Plastic packaging type IPM lead wire framework injection moulding guider

A lead frame and guiding device technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of great influence on module quality, influence on product insulation characteristics, difficult to grasp injection flow rate, etc. Yield, improve stability and reliability, improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

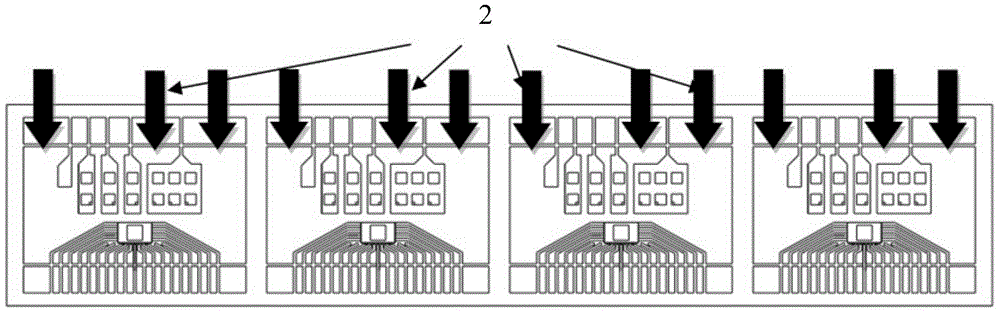

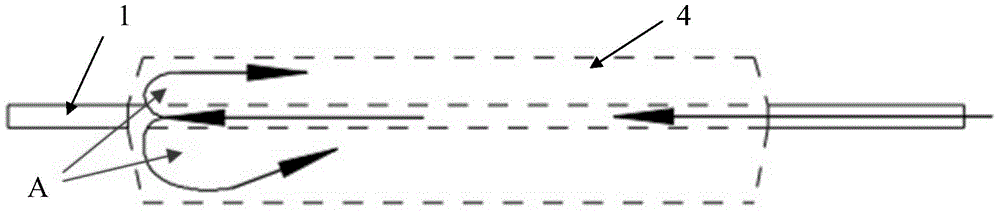

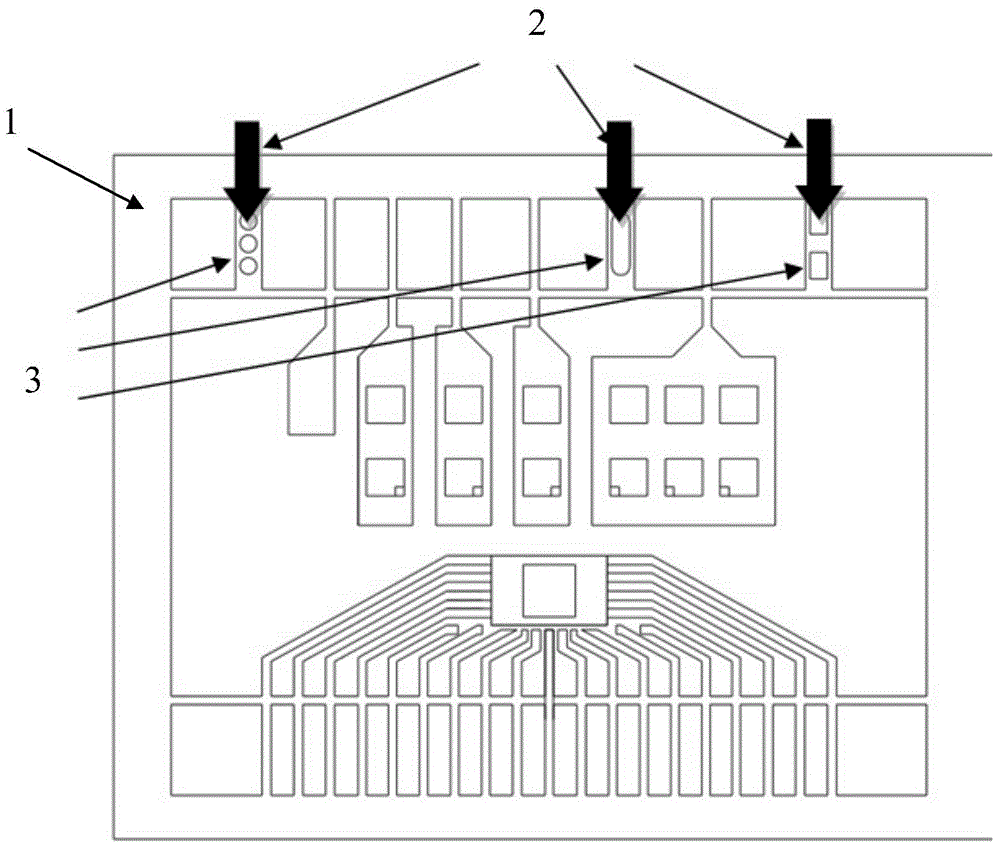

[0033] Please also see image 3 , Figure 4 , image 3 It is a schematic diagram of the structure of the lead frame disclosed in the present invention. Figure 4 It is a schematic structural diagram of the flow direction of the injection plastic in the present invention. As shown in the figure, a plastic-encapsulated IPM lead frame injection guide device, the injection guide device is an injection runner 2 arranged on the lead frame 1, and a deceleration shunt mechanism is arranged in the injection runner 2, and the deceleration shunt mechanism is at least one Hollow hole 3.

[0034] The injection plastic enters through the injection flow channel 2 on the lead frame 1 , and is blocked and shunted by the hollow hole 3 , and the injection plastic enters the injection tooling from the upper and lower sides of the lead frame 1 .

[0035] The structure of the hollow hole will have a corresponding blocking effect on the plastic injection, reducing the flow rate to a certain exte...

Embodiment 2

[0039] The rest is the same as the embodiment 1, the difference is that, in addition to the hollow holes, the injection flow channel 2 is also provided with a multi-stage flow blocking mechanism for blocking the injection plastic. Wherein, the multi-stage flow blocking mechanism is a protrusion (not shown) disposed on the surface of the injection flow channel 2 .

[0040] By setting the bulge, when the injection plastic shunted by the hollow hole 3 flows to the position of the bulge, the bulge will block the injection plastic, and at the same time, the shunted injection plastic will be shunted again, effectively reducing the bubbles and voids in the injection molding body. The amount of production, improve the insulation characteristics of products, improve product stability and reliability, improve product quality, improve production efficiency.

[0041] The protrusions can be integrally formed on the lead frame 1 .

[0042] Wherein, the multi-stage flow blocking mechanism c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com