Dual-output 3D printing four-degree-of-freedom decoupling parallel robot

A 3D printing and robotic technology, applied in the field of robotics, can solve problems affecting printing speed and printing accuracy, and size limitations of printed products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

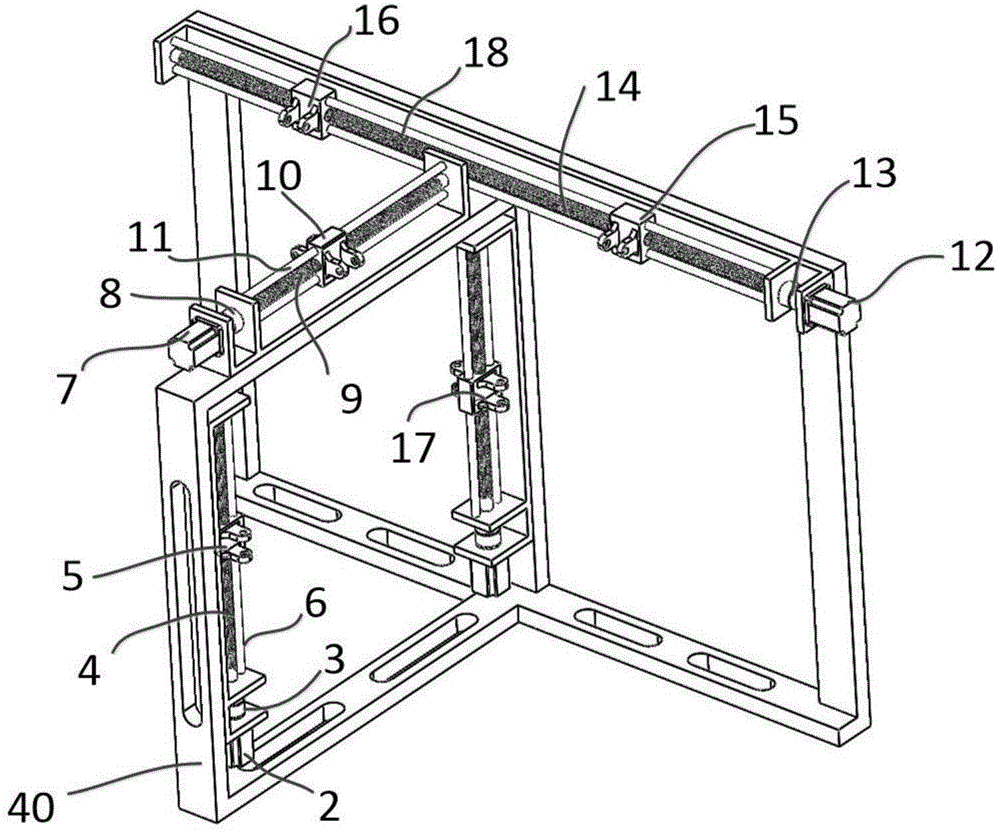

[0030] The present invention will be further described in conjunction with accompanying drawings.

[0031] Technical scheme of the present invention:

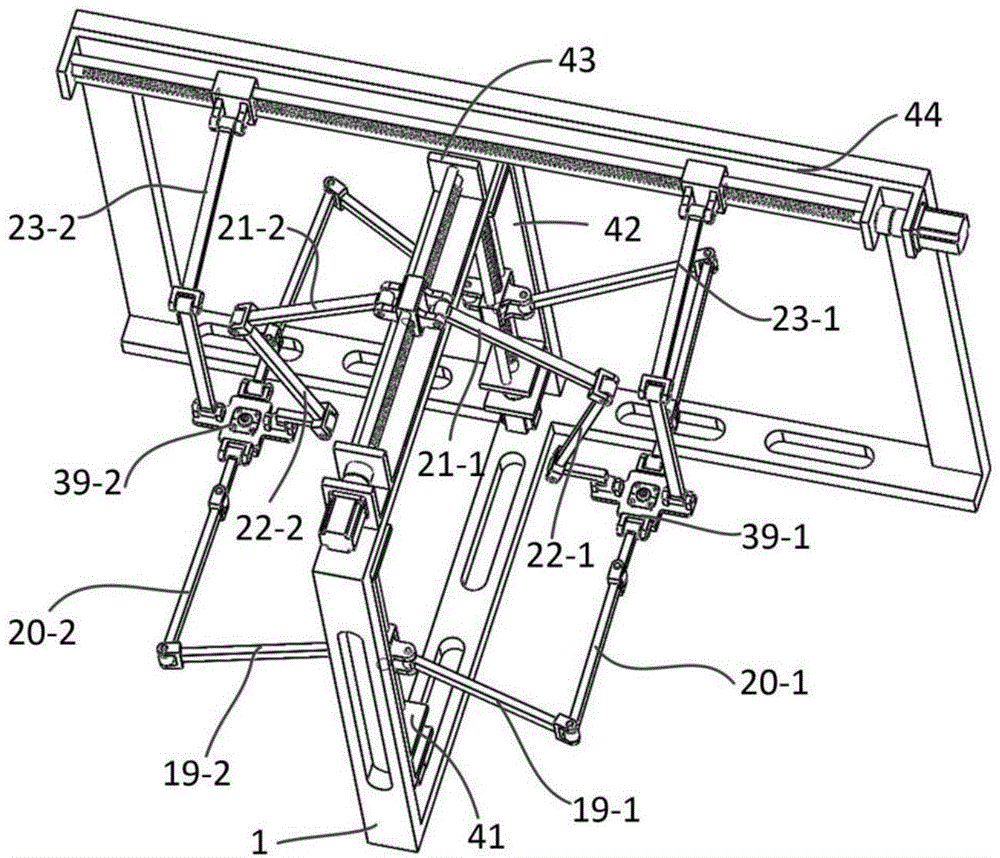

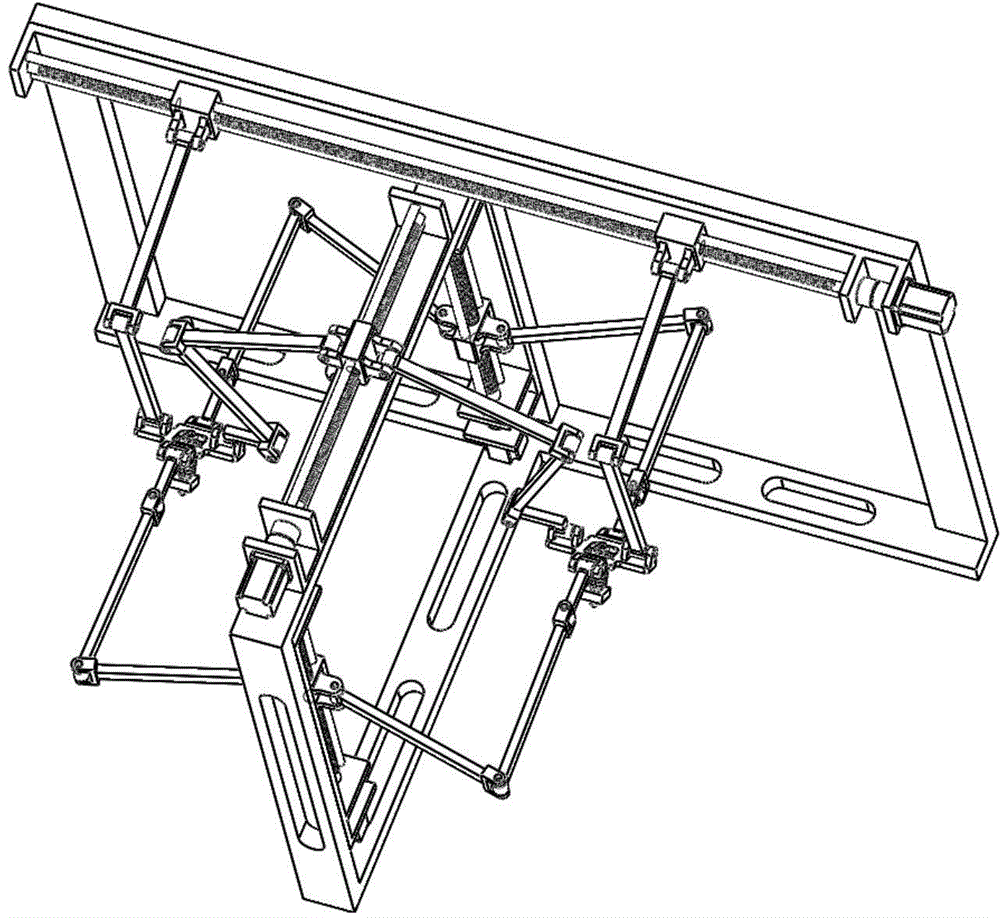

[0032]In the dual-output 3D printing decoupling parallel robot, the two ends of the vertically arranged symmetrical U-shaped slider 5 are respectively connected to the first connecting rod 19-1, the first connecting rod One end of 19-2 is connected to form a rotating pair; the other end of the first connecting rod 19-1 and the first connecting rod 19-2 pass through the installation shaft 24, bearing 25, bushing 26 and the second connecting rod 20-1, the second connecting rod One end of the two connecting rods 20-2 is connected to form a rotating pair; the other end of the second connecting rod 20-1 and the second connecting rod 20-2 pass through the installation shaft 24, bearing 25, axle sleeve 26 and one end of the third connecting rod connected to form a revolving pair; the other end of the third connecting rod 27-1, the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com