Automatic pushing type grinding device

An automatic and grinding mechanism technology, applied in the direction of grinding drive device, grinding workpiece support, grinding machine parts, etc., can solve the problem that there is no automatic push grinding mechanism, so as to improve labor efficiency, improve safety performance, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Embodiments of the present application will be described in detail below with reference to the drawings and examples.

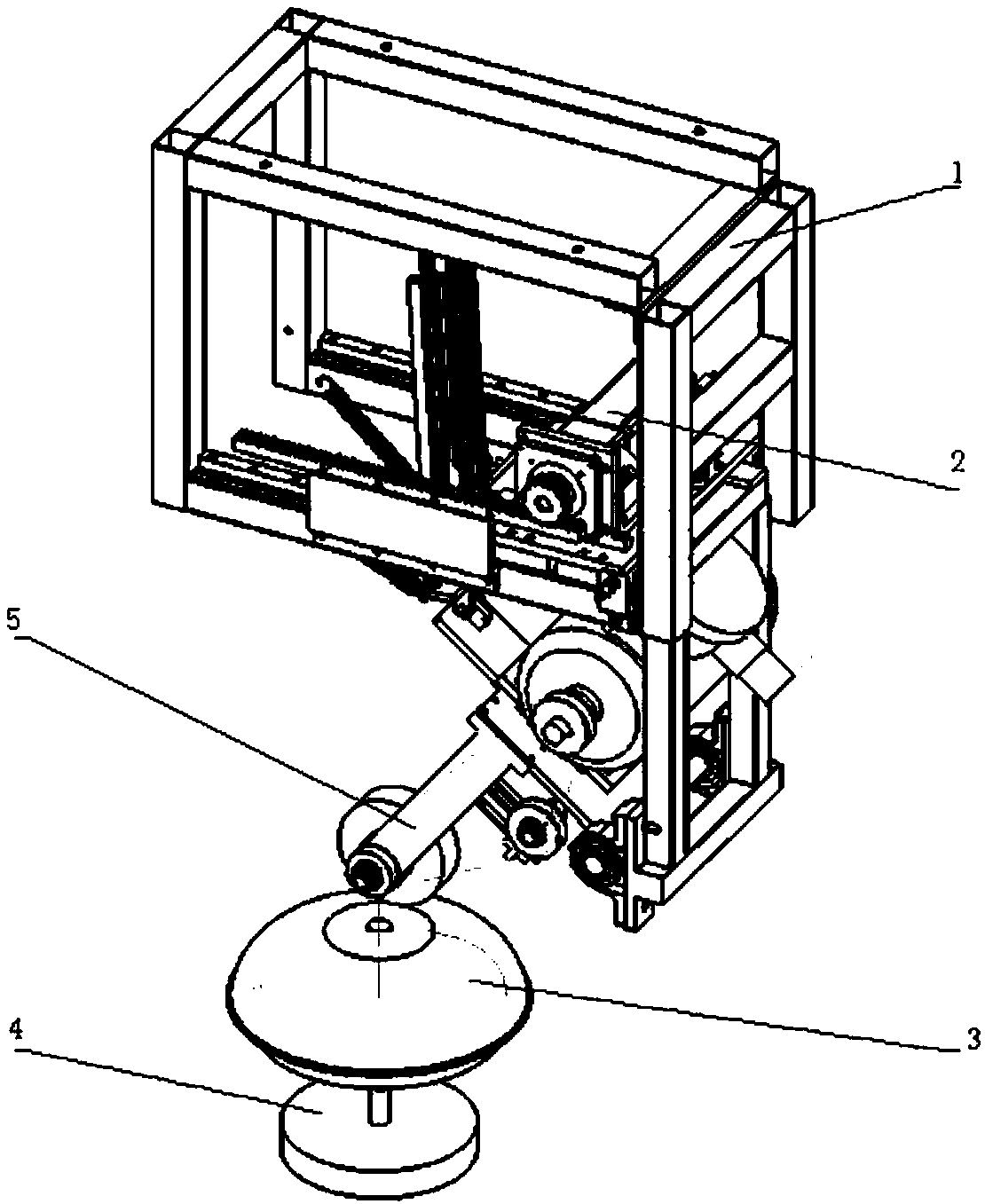

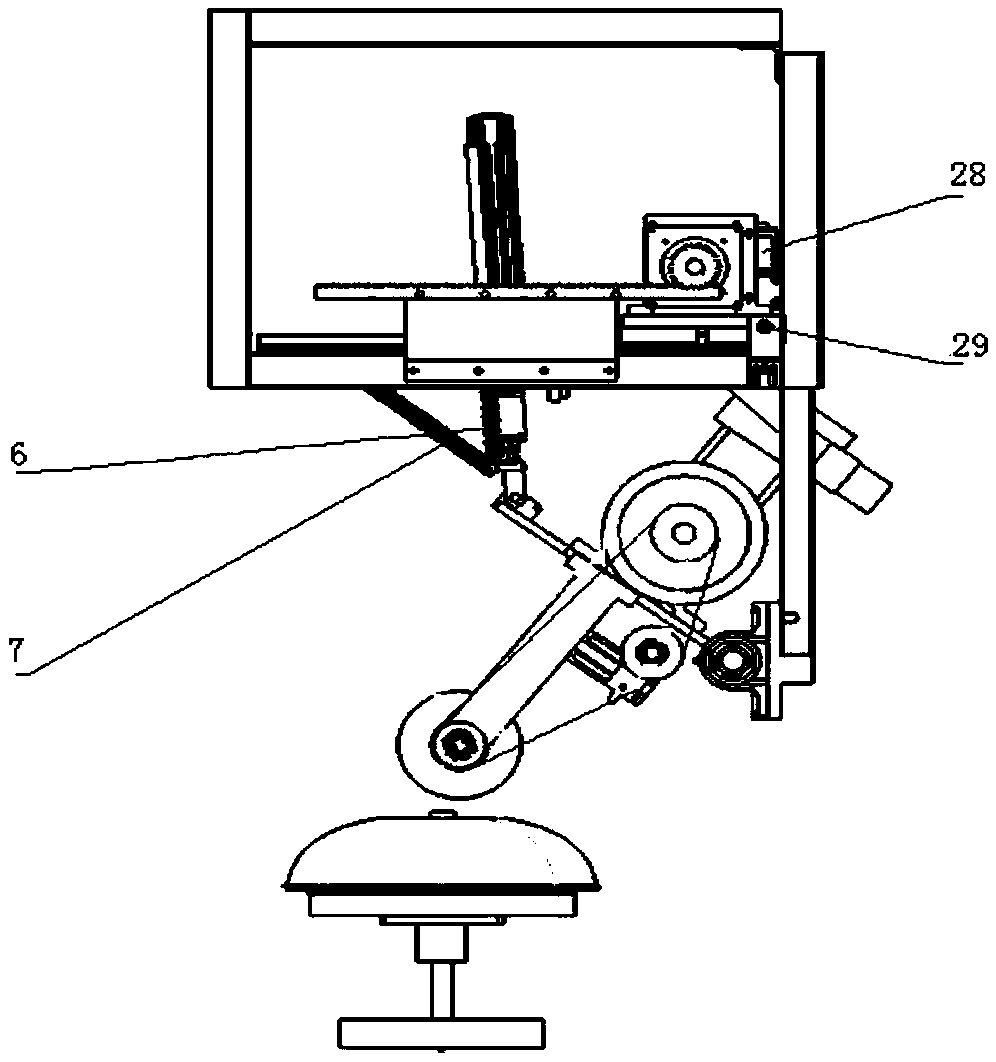

[0026] Such as Figure 1-Figure 5 As shown, the present invention provides an automatic push grinding device, which is composed of a translation mechanism 2, a grinding mechanism 5, and a jig 4.

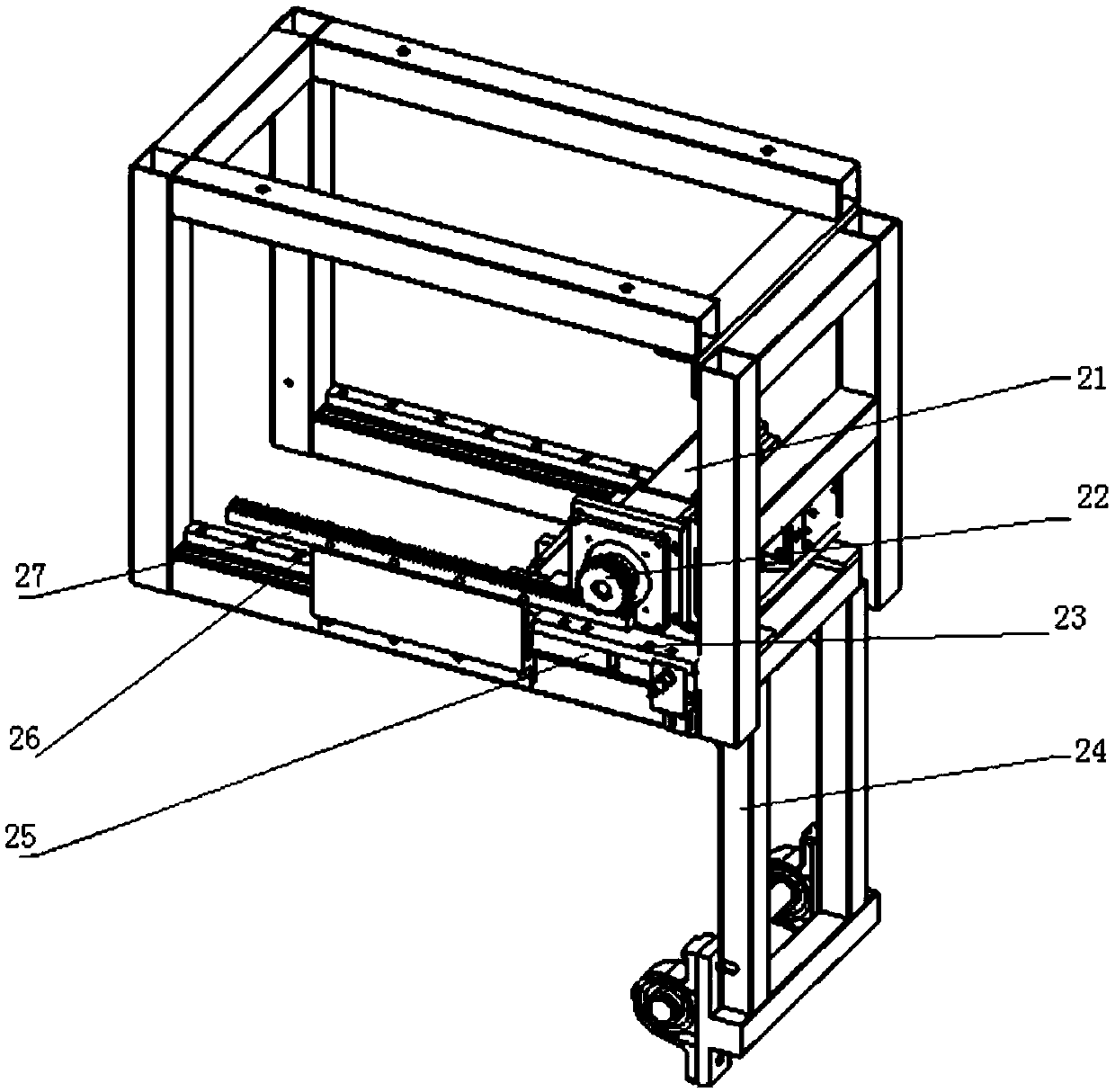

[0027] Such as image 3 As shown, translation mechanism 2 comprises fixed frame 1, translation motor mount 23 above fixed frame 1 and translation frame 24 below fixed frame 1, and translation motor 21 is installed on translation motor mount 23, and translation motor 21 is equipped with a gear 22, the fixed frame 1 is provided with a rack 27 meshing with the gear 22, and the fixed frame 1 is provided with a slide rail 26 and a slide block 25 matched with the slide rail 26, and the translation motor mount 23 and translation frame 24 are connected with slide block 25 respectively. The forward and reverse rotation of the translation motor 21 enables the transl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com