Translational gravity/acceleration measuring sensitive structure

A technology of acceleration measurement and sensitive structure, applied in the direction of speed/acceleration/shock measurement, measurement of acceleration, measurement device, etc., can solve the problems of complex assembly process and process, difficult to correct nonlinear effects, large volume and weight, etc., to eliminate Drift and instrument dropout error, increase the capacitance displacement sensing area, increase the effect of heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to facilitate those of ordinary skill in the art to understand and implement the present invention, the present invention will be described in further detail below in conjunction with the examples. It should be understood that the implementation examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

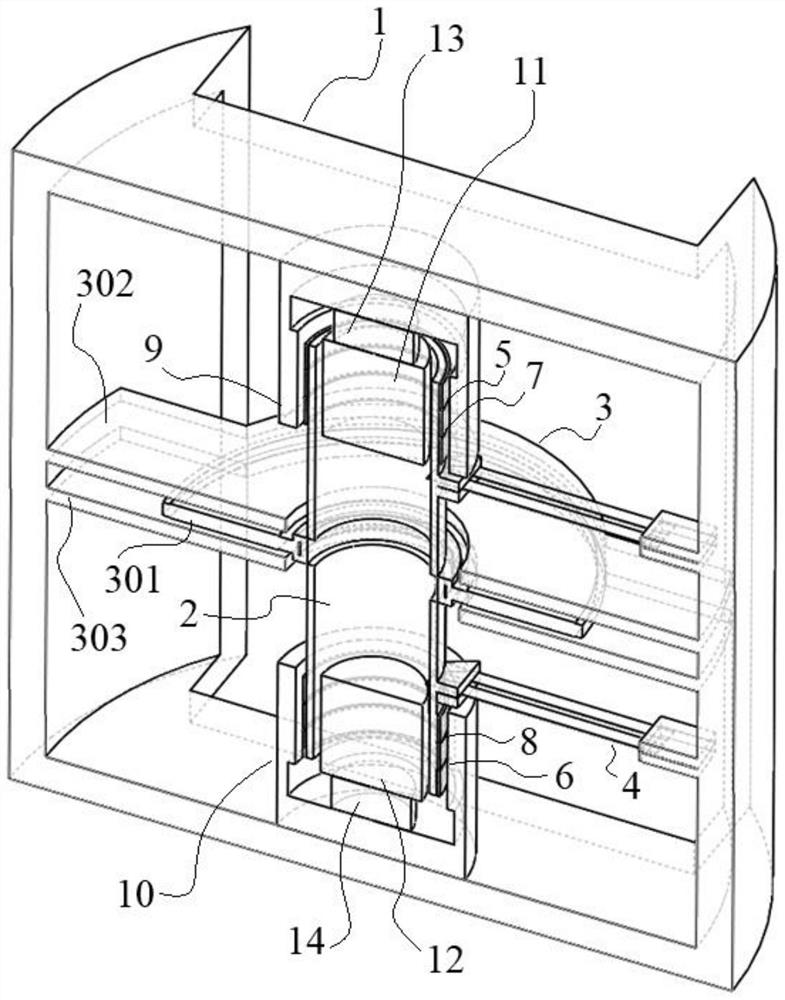

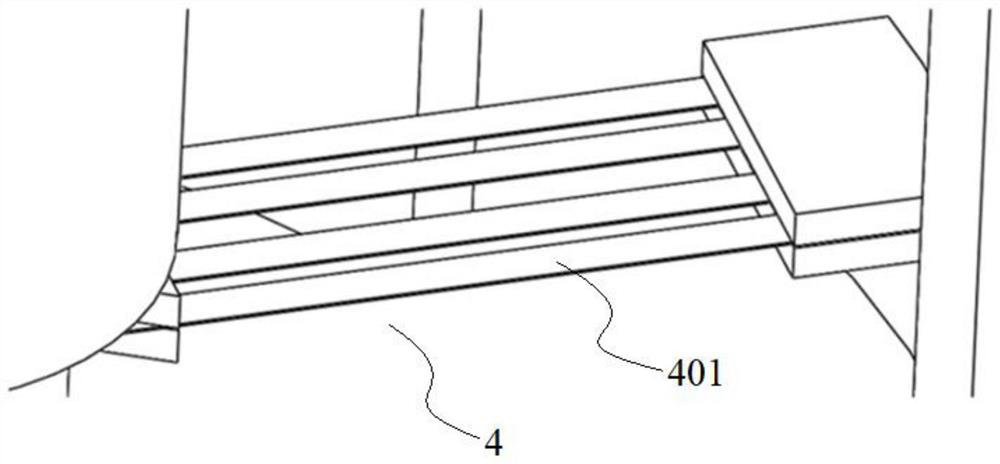

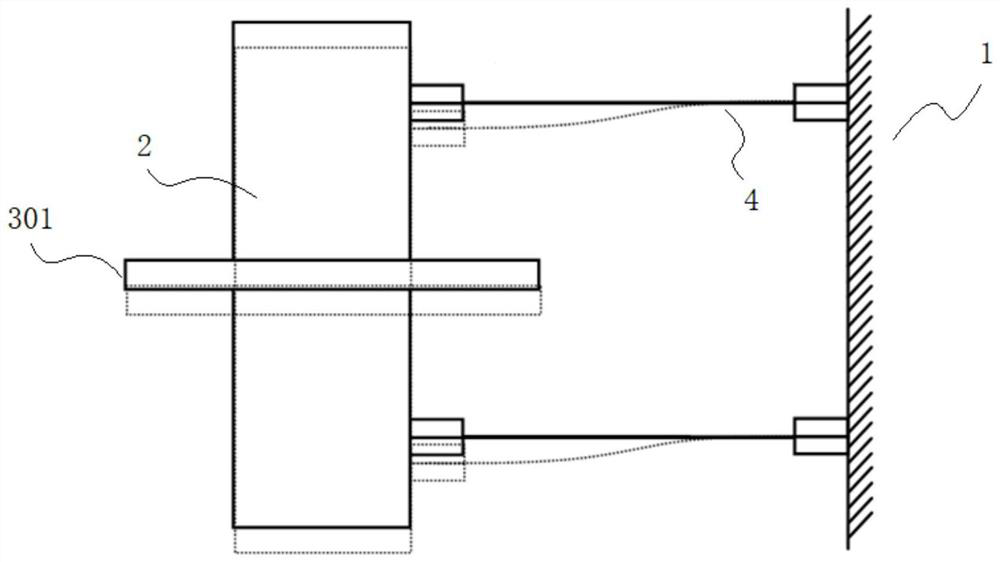

[0030] A translational gravity / acceleration measurement sensitive structure, including a frame 1, a sampling mass cylinder 2, a variable-pitch capacitive displacement sensor 3, and a reed set 4,

[0031] Frame 1: Fixedly connected to the frame of the gravity / acceleration measurement platform. The frame 1 can be a hollow cuboid, a medium-sized cylinder and other structural types. The upper and lower permanent magnets, the upper and lower magnetic cylinders, and the upper and lower magnetic guide blocks are all fixedly connected with the frame.

[0032]Sampling mass cylinder 2: in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com