Quick double-null-line wire threading device

A wire passing device, fast technology, applied to wire processing, other household appliances, household appliances, etc., can solve the problems of copper wire surface finish and shelf life, and achieve the effect of avoiding severe impact, good cleaning effect and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

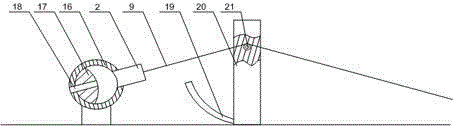

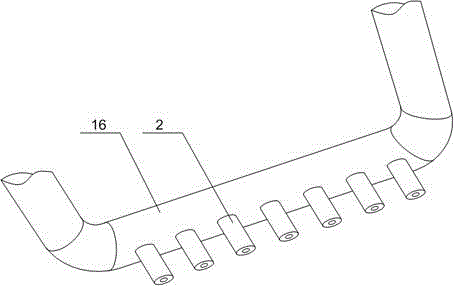

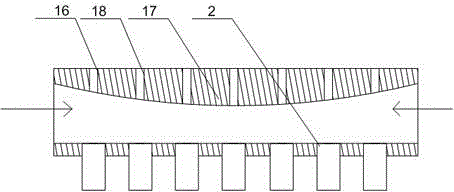

[0025] Such as Figure 1~Figure 5As shown, this embodiment includes a water absorption column 20, an air duct 16, and a plurality of air nozzles 2 arranged side by side on the air duct 16. A roller 21 is arranged inside the water absorption column 20, and copper wires 9 run through the water absorption column 20. And after the roller 17 changes direction, it is placed in the air nozzle 2. On the side of the water absorption column 20 close to the air duct 16, an arc-shaped return plate 19 is obliquely arranged. The inner wall is provided with a protrusion 17 with a circular arc-shaped cross section, and a plurality of wire passing holes 18 are opened on the air duct 16 on the same side as the protrusion 17. The apex of the protrusion 17 is located on the vertical line of the horizontal part of the air duct 16 , the two ends of the air nozzle 2 are respectively provided with an air inlet hole 1 corresponding to the wire hole 18 and two air outlet holes 4, and inside the air noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com