Preparation method of nickel-rich concentration gradient nickel-cobalt-manganese anode material with low acidity or alkalinity and high processability

A concentration gradient, cathode material technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of poor application, high pH, wide application of unfavorable materials, etc., to achieve excellent performance, low pH, novel preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

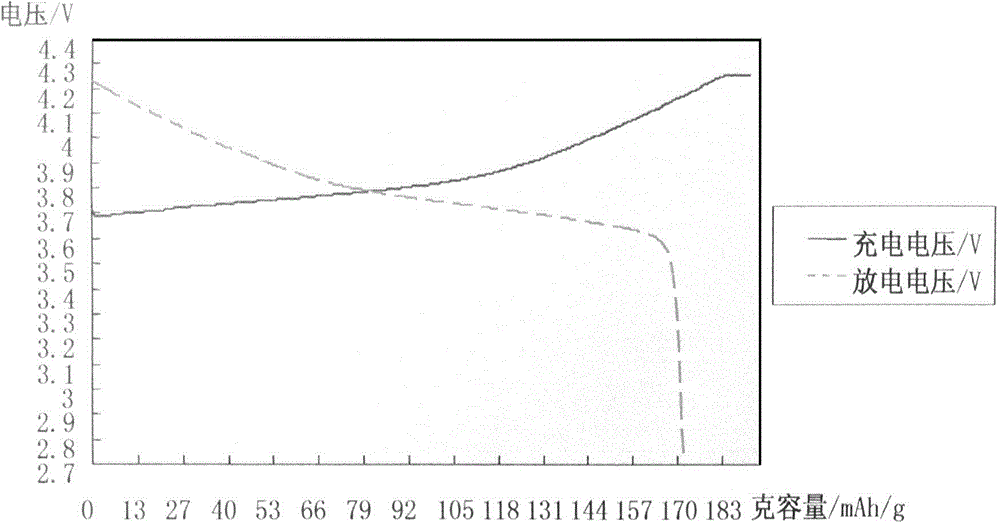

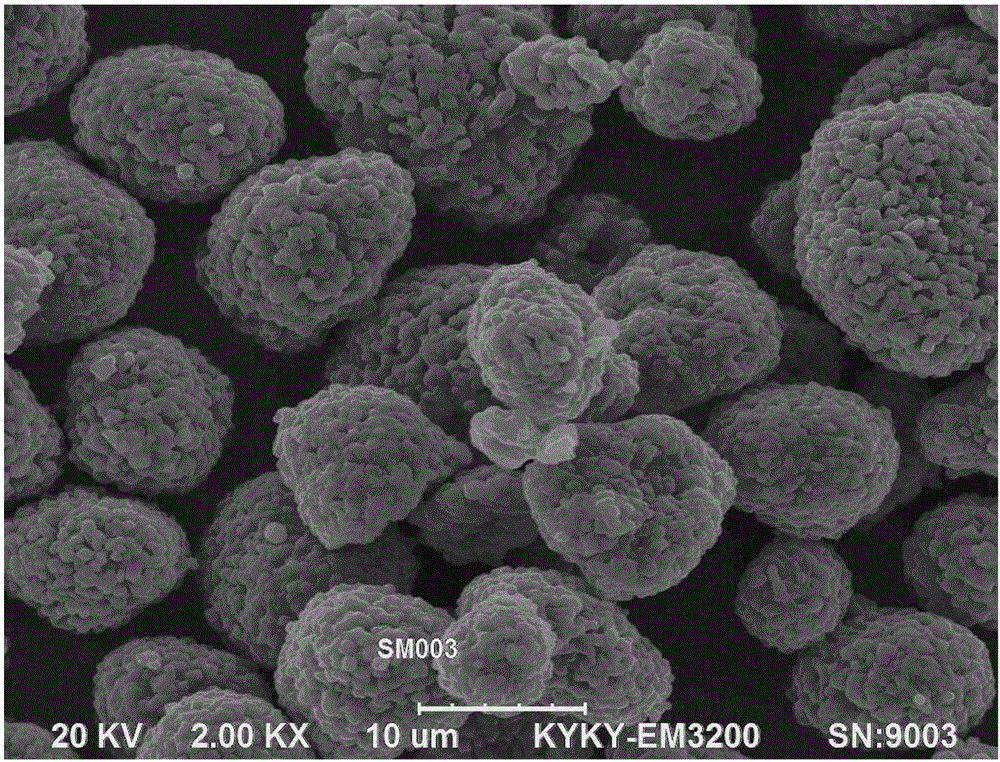

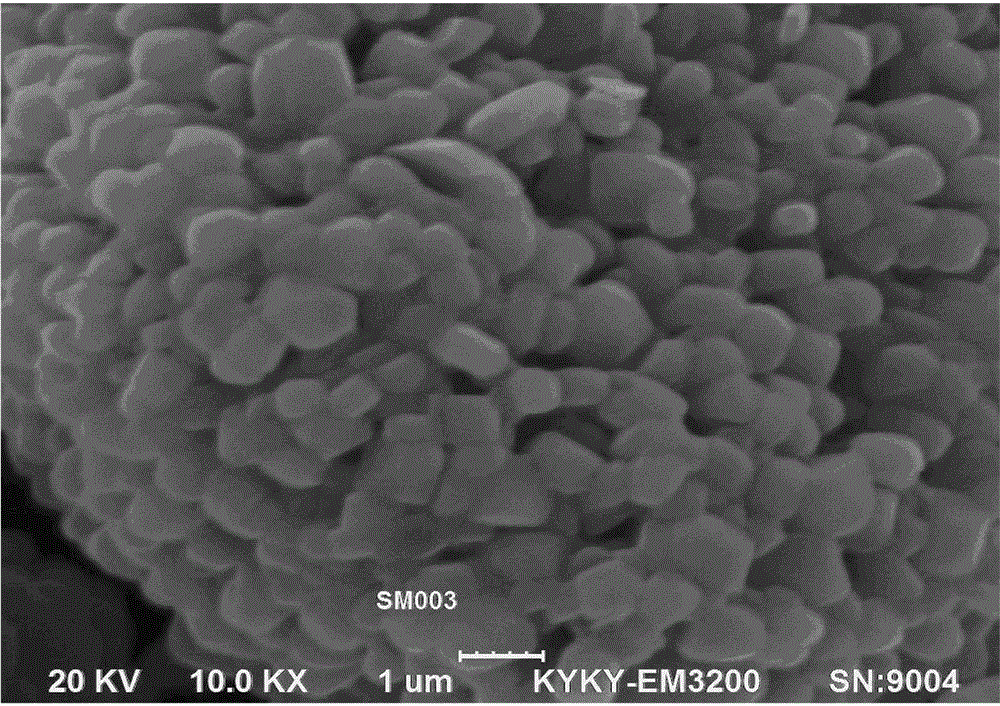

[0020] Example 1: Mix nickel-cobalt-manganese hydroxide (nickel: cobalt: manganese = 5:2:3) and lithium carbonate uniformly according to Li: M = 1.05, and heat at 850°C for 16 hours at a heating rate of 5°C / min , the airflow is controlled at 3 m 3 / h for the first sintering, cooling, ball milling, and Li 1.05 (Ni 0.5 co 0.2 mn 0.3 )O 2 Cathode material. Then carry out the first charge and discharge test, the first charge and discharge curve is shown in figure 1 , nickel cobalt lithium manganese oxide scanning electron imaging picture see figure 2 with image 3 .

Embodiment 2

[0021] Example 2: Mix nickel-cobalt-manganese hydroxide (nickel: cobalt: manganese = 5:2:3) and lithium carbonate uniformly according to Li: M = 1.05, and heat at 850 °C for 16 hours at a heating rate of 5 °C / min , the airflow is controlled at 3 m 3 / h for the first sintering, cooling, ball milling, and Li 1.05 (Ni 0.5 co 0.2 mn 0.3 )O 2 intermediate goods. Then the intermediate product and oxalic acid were uniformly mixed at a ratio of 1:0.2%, and kept at 300°C for 6 hours at a heating rate of 3°C / min, and the air flow was controlled at 5 m 3 / h for the second sintering, cooling, ball milling, and Li 1.05 (Ni 0.5 co 0.2 mn 0.3 )O 2 Cathode material. Then carry out the first charge and discharge test, the first charge and discharge curve is shown in figure 1 , nickel cobalt lithium manganese oxide scanning electron imaging picture see figure 2 with image 3 .

Embodiment 3

[0022] Example 3: Mix nickel-cobalt-manganese hydroxide (nickel: cobalt: manganese = 5:2:3) and lithium carbonate uniformly according to Li: M = 1.05, and heat at 850°C for 16 hours at a heating rate of 5°C / min , the airflow is controlled at 3 m 3 / h for the first sintering, cooling, ball milling, and Li 1.05 (Ni 0.5 co 0.2 mn 0.3 )O 2 intermediate goods. Then the intermediate product and oxalic acid were uniformly mixed at a ratio of 1:0.6%, and kept at 300°C for 6 hours at a heating rate of 3°C / min, and the air flow was controlled at 5 m 3 / h for the second sintering, cooling, ball milling, and Li 1.05 (Ni 0.5 co 0.2 mn 0.3 )O 2 Cathode material. Then carry out the first charge and discharge test, the first charge and discharge curve is shown in figure 1 , nickel cobalt lithium manganese oxide scanning electron imaging picture see figure 2 with image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com