Production method of NdFeB (Neodymium Iron Boron) radiation ring

A production method and radiation ring technology, applied in the manufacture of inductors/transformers/magnets, magnetic materials, electrical components, etc., can solve problems such as low production efficiency, directional arrangement damage, and poor squareness of characteristic curves, and achieve product qualification rate The effect of improving and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

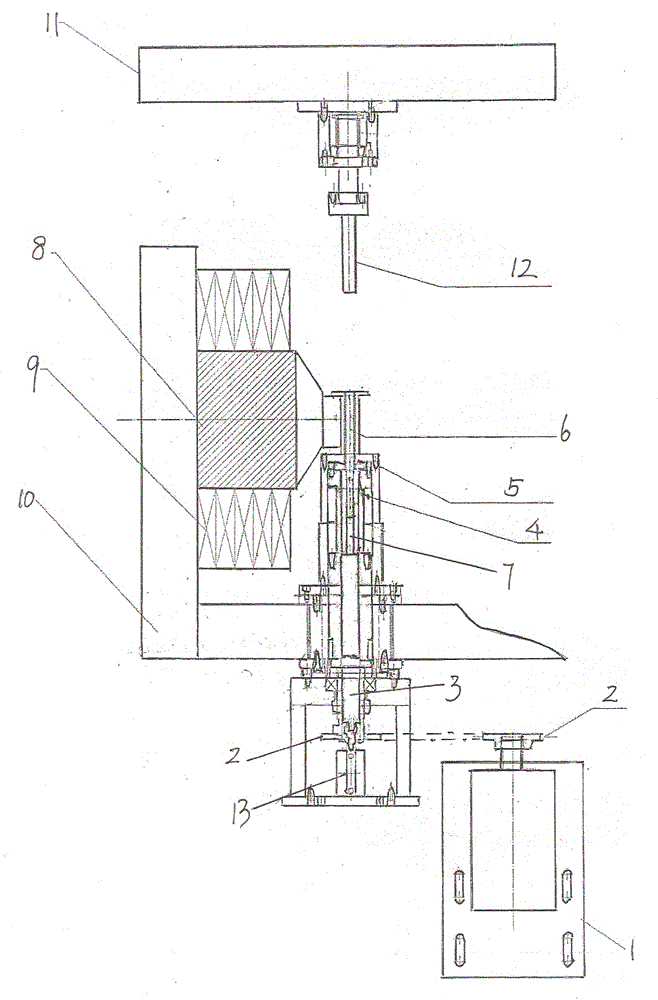

[0017] A method for producing NdFeB radiation rings, using a radiation ring forming device for production; the radiation ring forming device includes a sprocket mechanism 2 driven by a servo motor 1, the sprocket mechanism is connected to a transmission main shaft 3, and the upper part of the transmission main shaft is connected to a female mold The inner sleeve 4 is connected, the inner sleeve of the female mold is fixed outside the outer sleeve of the female mold and the outer jacket of the female mold 5, and the lower part of the female mold jacket is set outside the inner sleeve of the female mold, the upper part of the female mold jacket is located above the inner sleeve of the female mold, and the lower part of the female mold jacket The diameter is larger than the upper diameter of the female mold jacket; the mandrel is inserted into the upper part of the female mold jacket and the female mold inner sleeve, and the lower end of the mandrel 6 extends into the groove 7 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com