Device and method for testing fiber bragg grating corrosion and liquid refractive index

A technology of liquid refractive index and optical fiber grating, which is applied in the direction of measuring devices and instruments, can solve the problems of expensive micro-nano optical fiber drawing system and complexity, and achieve the effect of low production cost, simple structure and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. The embodiments of the present invention are implemented on the basis of existing technical solutions, but the present invention is not limited to the following embodiments.

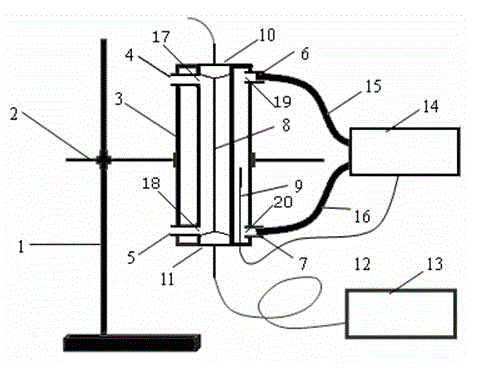

[0030] Such as figure 1 As shown, a fiber grating corrosion and liquid refractive index testing device includes a support frame 1 and a cross bar 2 on the support frame; The inner wall and the outer wall of the tube at the upper and lower ends of the side are provided with a through hole a17 and a through hole b18, and a columnar tube a4 and a columnar tube b5 are arranged in the through hole a17 and the through hole b18; The lower end is provided with a through hole c19 and a through hole d20, and the through hole c19 and the through hole d20 are respectively provided with a columnar tube c6 and a columnar tube d7; a temperature sensor 9 is provided in the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com