Boundary-changing fluid mechanism engine

A fluid mechanism and engine technology, which is applied in the direction of machines/engines, combustion engines, internal combustion piston engines, etc., to achieve the requirements of reducing temperature rise, reducing pressure bearing capacity, and the effect of fewer parts of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

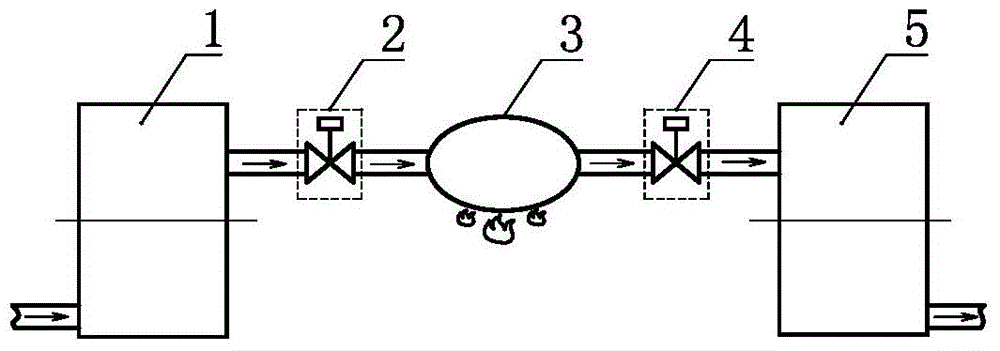

[0042] A variable boundary fluid mechanism engine, such as figure 1 As shown, it includes a variable boundary fluid mechanism 1 for compression, a gas compression control valve 2, a continuous working medium heater 3, a gas expansion control valve 4, and a variable boundary fluid mechanism 5 for expansion. The compression variable fluid mechanism 1, the The gas compression control valve 2, the working medium continuous heater 3, the gas expansion control valve 4 and the expansion fluid mechanism 5 are sequentially connected, and the working fluid inlet of the expansion fluid mechanism 5 is The ratio of the volume flow rate to the volume flow rate at the outlet of the working fluid mechanism 1 for compression is greater than 1.

Embodiment 2

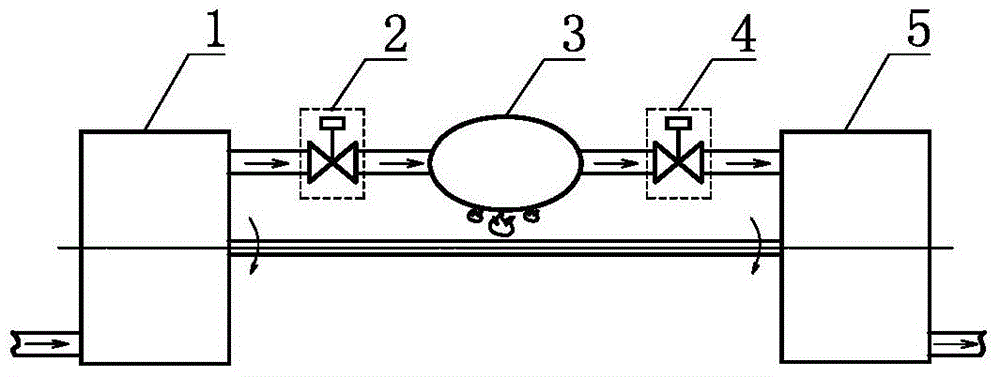

[0044] A variable boundary fluid mechanism engine, such as figure 2 As shown, on the basis of Embodiment 1, the boundary changing fluid mechanism 5 for expansion and the boundary changing fluid mechanism 1 for compression are further arranged in linkage.

Embodiment 3

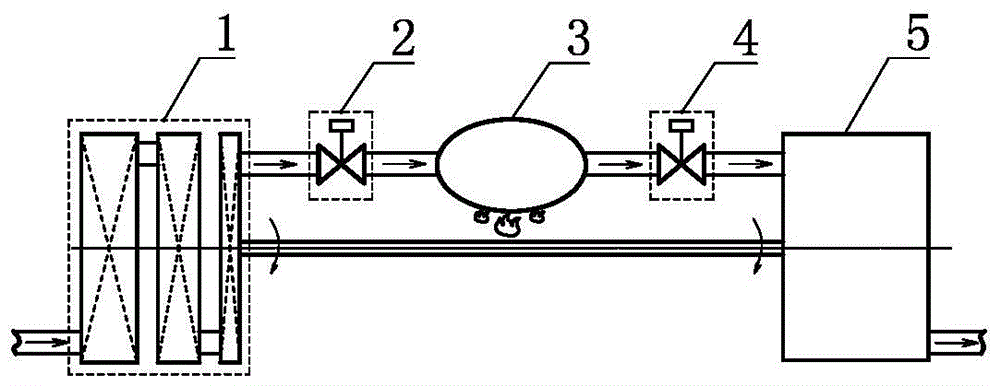

[0046] A variable boundary fluid mechanism engine, on the basis of Embodiment 2, further sets the variable boundary fluid mechanism 5 for expansion and the variable boundary fluid mechanism 1 for compression through a speed change mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com