Highly-dispersed carbon nano-tube composite electric conduction ink

A carbon nanotube composite, conductive ink technology, applied in the direction of carbon silicon compound conductors, conductive materials, conductive materials, etc., can solve problems such as the reduction of the electrical properties of surfactants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

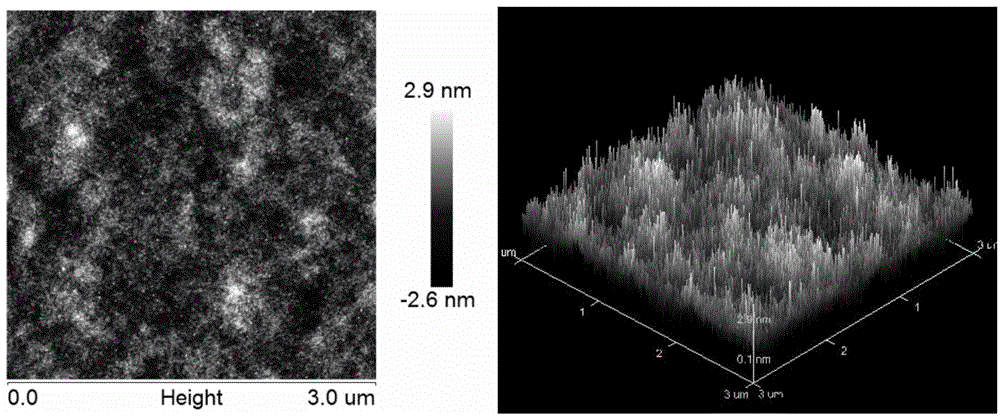

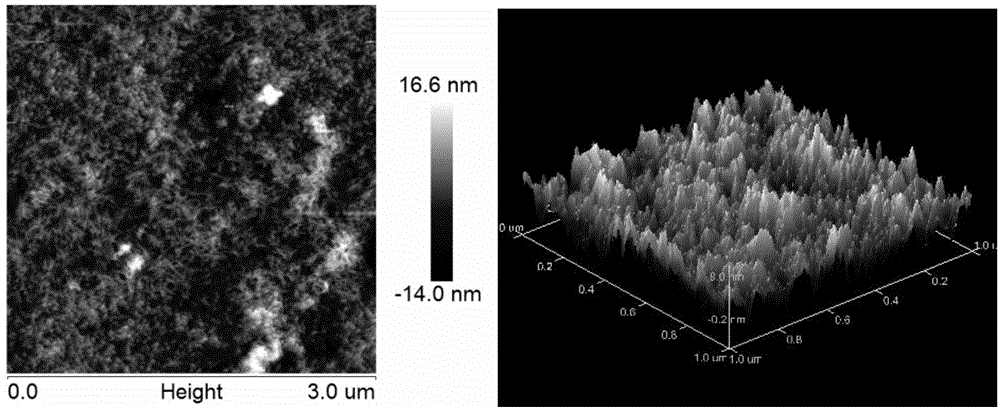

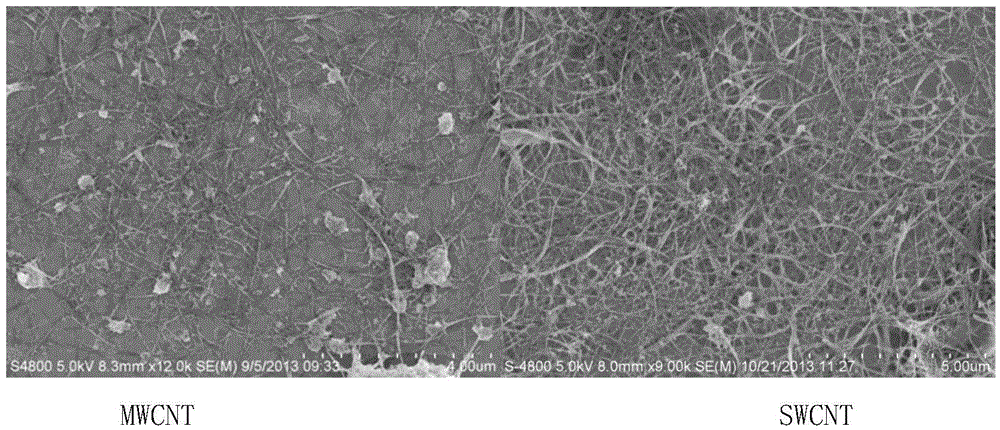

Image

Examples

Embodiment 1

[0029] Modified single-walled carbon nanotube methanol solution 10ml

[0030] 1.8% PEDOT: PSS aqueous solution of conductive polymer aqueous solution 20ml

[0031] Concentrate to a volume of 15ml.

[0032] Preparation method: 0.05 g of single-walled carbon nanotubes (SWCNTs) were ultrasonically dispersed in 20 ml of methanol for 20 min to form a SWNT suspension. Put the SWCNT suspension into a UV light cleaning machine for 40 minutes to obtain SWCNT powder; put 20ml of deionized water into a single-necked flask, and then add 10ml of concentrated HNO 3 (68wt%), add 5wt% ammonium persulfate (APS) aqueous solution, mix evenly, add the purified SWCNT powder, stir with a magnet, and reflux at 120°C for 5h. The deionized water was repeatedly washed by centrifugation (7000rpm, 10min) for 3 times, and the obtained single-walled carbon nanotubes were finally ultrasonically dispersed in methanol for 20min, and then centrifuged twice, and finally 10ml of methanol dispersion of SWCNT wa...

Embodiment 2

[0035] Modified multi-walled carbon nanotube (MWCNT) ethanol solution 20ml

[0036] 1.8%PEDOT:PSS aqueous solution 20ml

[0037] Preparation method: 0.05g of MWCNT is ultrasonically dispersed in 20ml of ethanol for 20min to form a MWCNT suspension. Put this MWCNT suspension into a UV light cleaning machine for 40min. The obtained MWCNT powder was ultrasonically cleaned with 20ml of DMF and TFA mixture (9:1 / Vol) for 30-60min, centrifuged at 7000rpm, and then repeated ultrasonically for a total of 5 times. Finally, ultrasonically dispersed with ethanol for 20min, and then centrifuged , repeated twice, and finally 20ml of ethanol dispersion of MWCNT was obtained.

[0038] Mix 20ml of 1.8% PEDOT:PSS with 10ml of MWCNT ethanol dispersion evenly, and concentrate to 15ml (weighing about 15 grams), to form a uniformly dispersed MWCNT / PEDOT:PSS ink solution.

Embodiment 3

[0040] Modified SWCNT methanol 10ml

[0041] 1.8%PEDOT:PSS aqueous solution 20ml

[0042]Preparation method: 0.05 g of single SWNT is dispersed in 20 ml of methanol, and the SWNT suspension is formed after ultrasonic dispersion for 20 min. Put the SWNT suspension into a UV light cleaning machine for 40 minutes to obtain SWNT powder; take 20ml of concentrated sulfuric acid and put it into a single-necked flask, add the purified single-wall SWNT powder, stir magnetically, and swell at room temperature for 12 hours. After diluting the mixed concentrated sulfuric acid solution of SWNT with 10:1 water, the centrifugation was carried out and repeated 4 times. Finally, a single-walled SWNT powder is obtained. Put this powder into a single-necked flask, add 20ml of deionized water, and then add 10ml of concentrated HNO 3 (68wt%), add 10ml H 2 o 2 , magnetic stirring, reflux reaction at 85°C for 5h. Repeated centrifugal washing (7000rpm, 10min) with deionized water for 3 times, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com