A kind of transparent glass heat insulation material and its application

A technology for transparent glass and thermal insulation materials, applied in the direction of polyurea/polyurethane coatings, film/flaky adhesives, coatings, etc., can solve the problem of increasing ATO and ITO thermal insulation materials, affecting ATO and ITO thermal insulation materials Heat insulation effect and other issues, to achieve the effect of good heat insulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

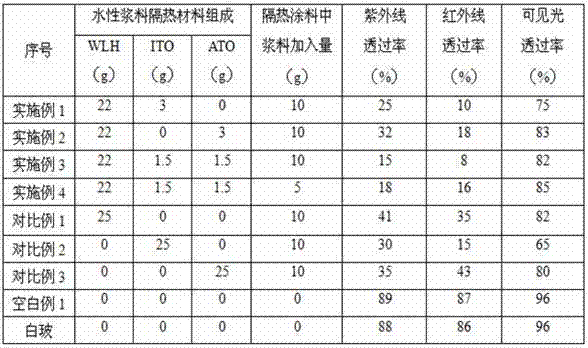

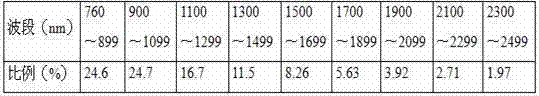

[0030] Transparent glass heat insulation material: WLH, ITO and ATO are mixed and prepared according to a certain ratio. The specific mixture is shown in Table 1 to obtain transparent glass heat insulation materials I to IV.

[0031] Preparation of water-based slurry for transparent glass heat insulation materials: add 0.5g of SN5050 dispersant and 0.2g of CF-10 wetting agent to 70g of deionized water respectively, stir evenly, add 25g of one of transparent glass heat insulation materials I to IV, Disperse with a high-speed disperser at a speed of 1000 rpm for 30 minutes, then add 0.5 g of RM2020 leveling thickener, grind until the particle size is 10-30 nm, and then obtain water-based slurries I to IV for transparent glass heat insulation materials.

[0032] Preparation of water-based heat-insulating coating for transparent glass: Water-based slurry I to IV of transparent glass heat-insulating material (the specific addition amount is shown in Table 1), 100 g of heat-crosslink...

Embodiment 5~9

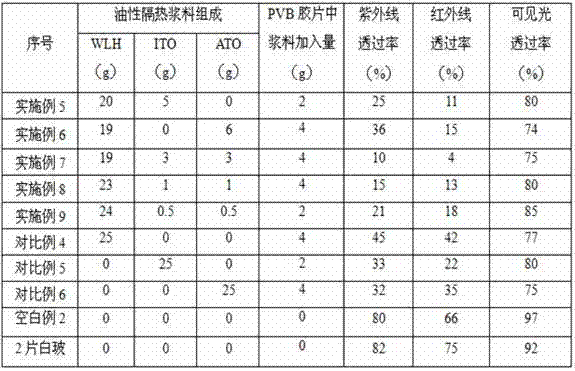

[0048] Transparent glass heat insulation material: WLH, ITO and ATO are mixed and prepared according to a certain ratio. The specific mixture is shown in Table 2 to obtain transparent glass heat insulation materials V-IX.

[0049] Preparation of oily slurry for transparent glass heat insulation materials: Add 25g of transparent glass heat insulation materials Ⅴ~Ⅸ to 75g of triethylene glycol diisocaprylate plasticizer respectively, disperse at a speed of 500 rpm for 30 minutes at a low speed, and grind When the particle size reaches 10-30nm, oily pastes V-IX for transparent glass heat insulation materials are obtained.

[0050] Preparation of heat-insulating polyvinyl butyral film for transparent glass: respectively add oily slurry Ⅴ~Ⅸ of heat-insulating material for transparent glass (see Table 2 for the specific addition amount) into 100g of polyvinyl butyral resin, stir After uniformity, add 20g of triethylene glycol diisocaprylate plasticizer, stir well, and mold on a PVB ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com