Brown porous inorganic solid pigment synthesis method

A technology of inorganic solids and synthesis methods, applied in inorganic pigment processing, chemical instruments and methods, fibrous fillers, etc., can solve the problem of affecting color chromaticity and stability, easily changing the adsorption amount of organic dyes, affecting the distance between compounds and adsorption space, etc., to achieve the effect of stable adsorption capacity, increased specific surface area, and no pollution to the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

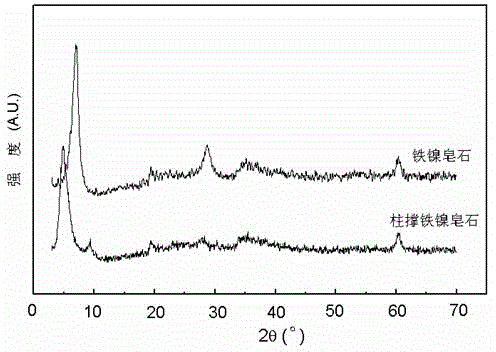

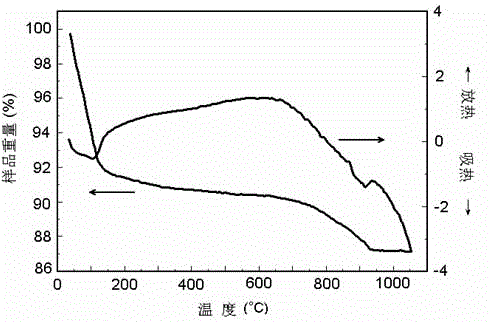

[0020] At room temperature, 38.3 milliliters of water glass solution is added dropwise in the aqueous solution that is dissolved with 9.26 gram of nickel chloride hexahydrate and 1.35 gram of ferric chloride hexahydrate, vigorously stirs during the dropping process, the molar proportion of various raw materials is : iron in ferric chloride: silicon in water glass: nickel in nickel chloride = 1: 7.8: 8.1, after stirring for 10 minutes, add dropwise 0.1mol / L sodium hydroxide solution to the solution to adjust the pH to 8.5, continue to stir, then transfer the obtained tan turbid liquid to a stainless steel reactor and seal it, react at 270°C for 20 hours, then wash, filter, and dry to obtain tan saponite; take 10 grams of the above-mentioned synthesized iron Nickel saponite is added to a pillar solution formed by adding 13 polyhydroxy aluminum containing 25 mmoles of aluminum (the molecular formula of 13 polyhydroxy aluminum is [AlO 4 Al 12 (OH) 24 (H 2 O) 12 ] 7+ , the con...

Embodiment 2

[0022] At room temperature, 34.4 milliliters of water glass solution will be added dropwise to the aqueous solution in which 8.71 grams of nickel nitrate hexahydrate and 1.35 grams of ferric chloride hexahydrate are dissolved, vigorously stirred during the dropping process, and the molar ratio of various raw materials is : iron in ferric chloride: silicon in water glass: nickel in nickel nitrate = 1.0: 7.0: 6.0, after stirring for 20 minutes, sodium hydroxide solution was added dropwise in the solution to adjust the pH to 9.0, continue to stir, and then The tan turbid liquid obtained is transferred to a stainless steel reactor and sealed, reacted at 290°C for 60 hours, then washed, filtered, and dried to obtain tan saponite; 10 grams of the above-mentioned synthetic iron-nickel saponite was added to the Pillar solution formed by 13 polyhydroxyaluminum with 50 mmoles of aluminum (13 polyhydroxyaluminum molecular formula is [AlO 4 Al 12 (OH) 24 (H 2 O) 12 ] 7+ , the concent...

Embodiment 3

[0026] At room temperature, 21.1 milliliters of water glass solution is added dropwise in the aqueous solution that is dissolved with 5.25 grams of nickel sulfate hexahydrate and 1.35 grams of ferric chloride hexahydrate, vigorously stirs during the dropping process, and the molar ratio of various raw materials is: Iron in ferric chloride: silicon in water glass: nickel in nickel sulfate = 1:4.3:4, after stirring for 30 minutes, add sodium hydroxide solution dropwise to the solution, adjust the pH to 10.0, continue stirring, and then add The tan turbid liquid obtained is transferred to a stainless steel reactor and sealed, and reacted for 48 hours at 285° C., then washed, filtered, and dried to obtain tan saponite; 10 grams of the above-mentioned synthetic iron-nickel saponite was added to the A pillared solution prepared by millimoles of aluminum thirteen polyhydroxyaluminum (the molecular formula of thirteen polyhydroxyaluminum is [AlO 4 Al 12 (OH) 24 (H 2 O) 12 ] 7+ , ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com