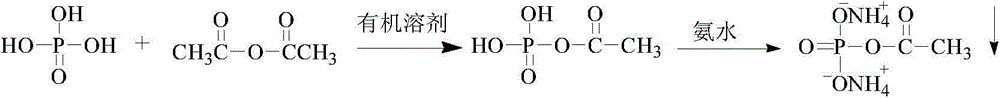

Preparation method of acetyl diammonium phosphate

A technology of acetyl phosphate diammonium salt and phosphoric acid, which is applied in the field of medicine, can solve problems such as hidden dangers, safety, and contamination at the entrance, and achieve the effects of being suitable for industrial production, reducing equipment requirements, and moderate reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 1L four-neck flask, add 80ml of ethyl acetate, add 54ml (0.79mol) of 85% industrial phosphoric acid under ice-water bath conditions, stir well, then slowly add 150ml (1.58mol) of acetic anhydride, and control the reaction temperature at 15°C. After the addition, the reaction was incubated for 0.5 hours. After the reaction, slowly add 118ml (1.74mol) of 28% concentrated ammonia water to keep the reaction internal temperature at 10°C. After the addition, keep stirring for 2 hours, filter, and dry to obtain 123g of acetyl phosphate diammonium salt solid (purity 98.3% ), the product yield is 90%.

Embodiment 2

[0031] In a 2L four-neck flask, add 320ml of ethyl acetate, add 108ml (1.58mol) of 85% industrial phosphoric acid under ice-water bath conditions, stir evenly, then slowly add 300ml (3.16mol) of acetic anhydride, and control the reaction temperature at 15°C. After the addition, the reaction was incubated for 0.5 hours. After the reaction, slowly add 28% concentrated ammonia water 257ml (3.8mol), keep the reaction temperature at 5°C, after the addition, keep stirring for 1.5h, filter, and dry to obtain 254g of acetyl phosphate diammonium salt solid (purity 98.5 %), product yield 93%.

Embodiment 3

[0033] In a 0.5L four-neck flask, add 40ml of acetonitrile, add 38.5g (0.39mol) of 100% industrial phosphoric acid under ice-water bath conditions, stir evenly, then slowly add 68ml (0.72mol) of acetic anhydride, and control the reaction temperature at 20°C. After the addition, the reaction was incubated for 0.5 hours. After the reaction is over, slowly add 28% concentrated ammonia water 58ml (0.86mol) to keep the reaction temperature at 5°C. After the addition, keep stirring for 2 hours, filter, and dry to obtain acetyl phosphate diammonium salt solid 59.7g (purity 98.2 %), product yield 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com