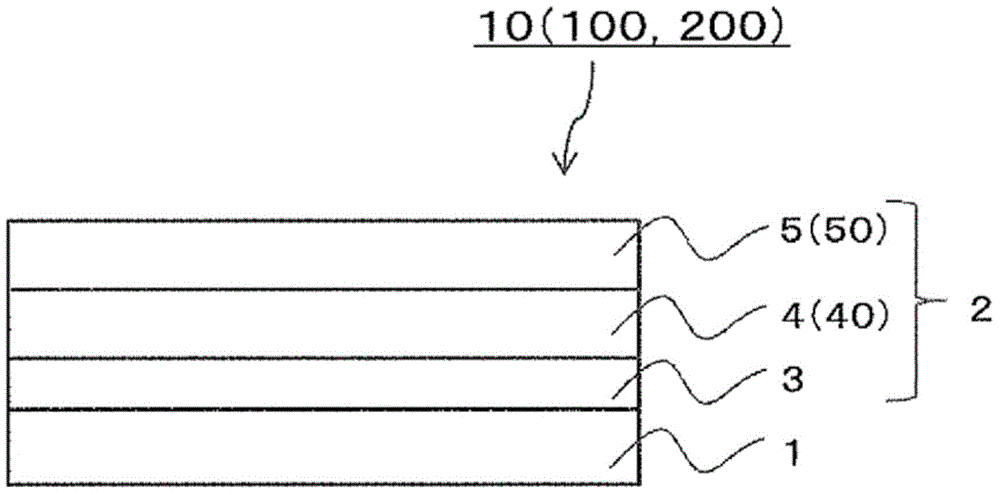

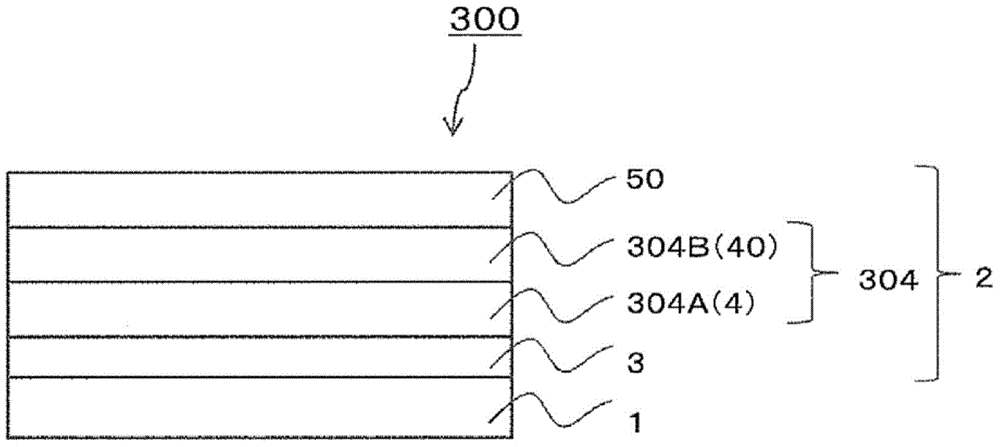

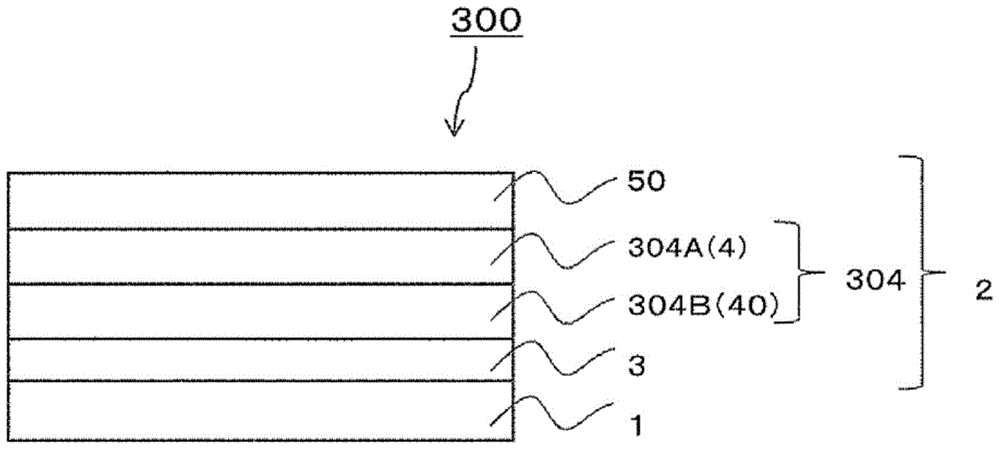

Intermediate transfer medium

An intermediate transfer, medium technology, applied in printing, printing device, post-processing of printing, etc., can solve the problems of poor coating stability, coating cracks, protective layer cracks, etc., to achieve excellent plasticizer resistance, simple Excellent effect of durability and coating film stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0140] A PET film with a thickness of 12 μm was used as a base material, and a release layer-forming coating liquid having the following composition was applied to one side of the base material by a bar coating method, dried to a thickness of 0.8 μm, and dried to form a release layer. Next, a coating solution 1 for forming a protective layer having the following composition was applied on the peeling layer by bar coating, dried to a thickness of 1.0 μm, and dried to form a protective layer. Next, a receiving layer-forming coating solution 1 having the following composition was applied on the protective layer by bar coating, dried to a thickness of 2.5 μm, and dried to form a receiving layer, whereby the intermediate transfer medium of Example 1 was obtained.

[0141]

[0142] ·Acrylic

[0143] 100 copies

[0144] (BR-87 (manufactured by Mitsubishi Rayon Co., Ltd.)

[0145] ·Toluene

[0146] 200 copies

[0147] ·MEK

[0148] 200 copies

[0149]

[0150] ·Polyvinyl alc...

Embodiment 2

[0169] The intermediate transfer medium of Example 2 was obtained in the same manner as in Example 1 except that the protective layer forming coating liquid 1 was changed to the protective layer forming coating liquid 2 having the following composition.

[0170]

[0171] ·Polyvinyl butyral

[0172] 10 copies

[0173] (BM-5 degree of saponification: 34.0% manufactured by Sekisui Chemical Co., Ltd.)

[0174] ·MEK

[0175] 45 copies

[0176] ·Toluene

[0177] 45 copies

Embodiment 3

[0179] The intermediate transfer medium of Example 3 was obtained in the same manner as in Example 1 except that the protective layer-forming coating liquid 1 was changed to the protective layer-forming coating liquid 3 having the following composition.

[0180]

[0181] · Polyvinyl acetal

[0182] 50 copies

[0183] (KX-1 degree of saponification: 70.0 to 90.0% manufactured by Sekisui Chemical Co., Ltd.)

[0184] ·water

[0185] 25 copies

[0186] ·IPA

[0187] 25 copies

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com