Coating composition for use in ship with reduced friction drag utilizing gas-lubricating function in water, coating film formed from said composition, ship coated with said coating film, method for manufacturing said ship, method for predicting said friction drag reduction effect, device used for prediction of said friction drag reduction effect, and friction drag reduction system for use in said ship with reduced friction drag

A technology of frictional resistance and gas lubrication applied to a coating composition for reducing frictional resistance of a ship utilizing the gas lubrication function in water, a coating film formed from the composition, a ship coated with the coating film, and manufacture of the ship , the field of predicting the above-mentioned frictional resistance reduction effect, a device for predicting the above-mentioned frictional resistance reduction effect, and a frictional resistance reduction system for the above-mentioned frictional resistance reduction ship, capable of solving problems such as lack of practicality and marine pollution in the atmosphere, Achieve the effects of reducing frictional resistance of water flow, preventing adhesion of aquatic organisms, and excellent frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0359] Hereinafter, the present invention will be described in more detail with reference to examples, but the present invention is not limited to these examples. In addition, unless otherwise specified, the pressure condition is normal pressure (about 0.1013 MPa), and the temperature condition is normal temperature (about 25° C.).

[0360] Details of various tests performed in each of the following Examples and Comparative Examples are as follows.

[0361]

[0362] According to JIS B 0601, the surface state of each coating film was measured using a stylus surface roughness meter (HANDYSURF E-35A, manufactured by Tokyo Precision Co., Ltd. (Tokyo Precision Co., Ltd.)).

[0363]

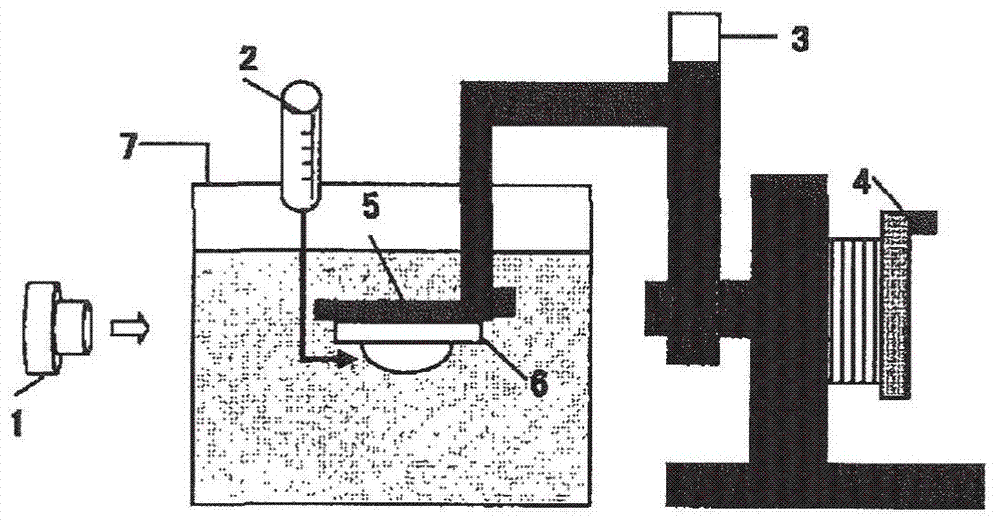

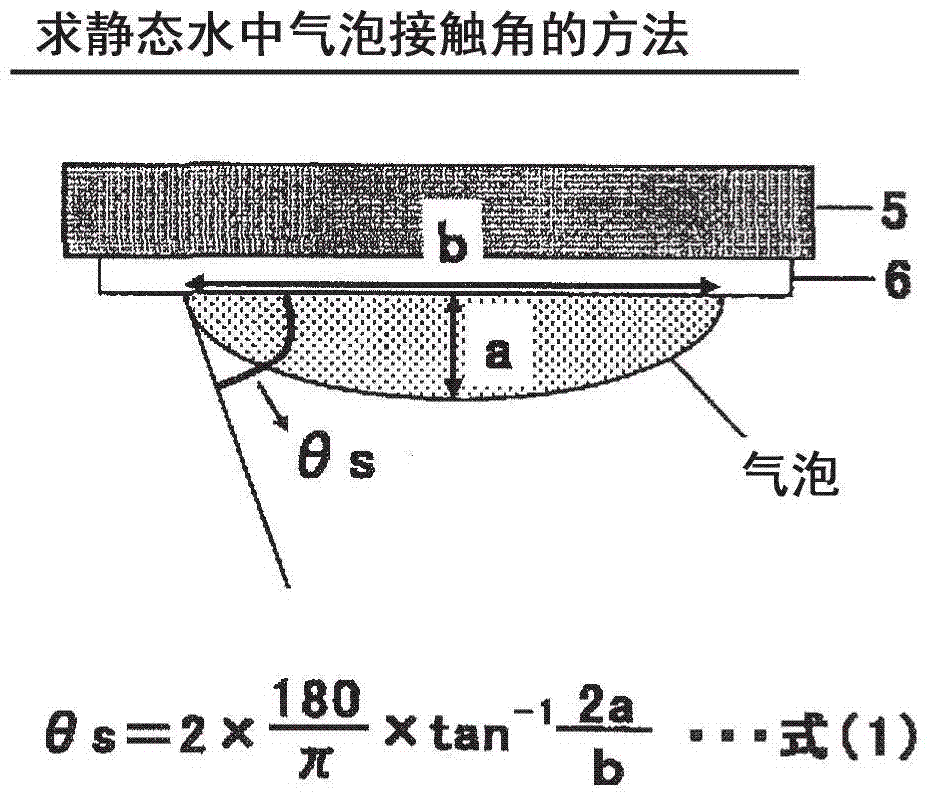

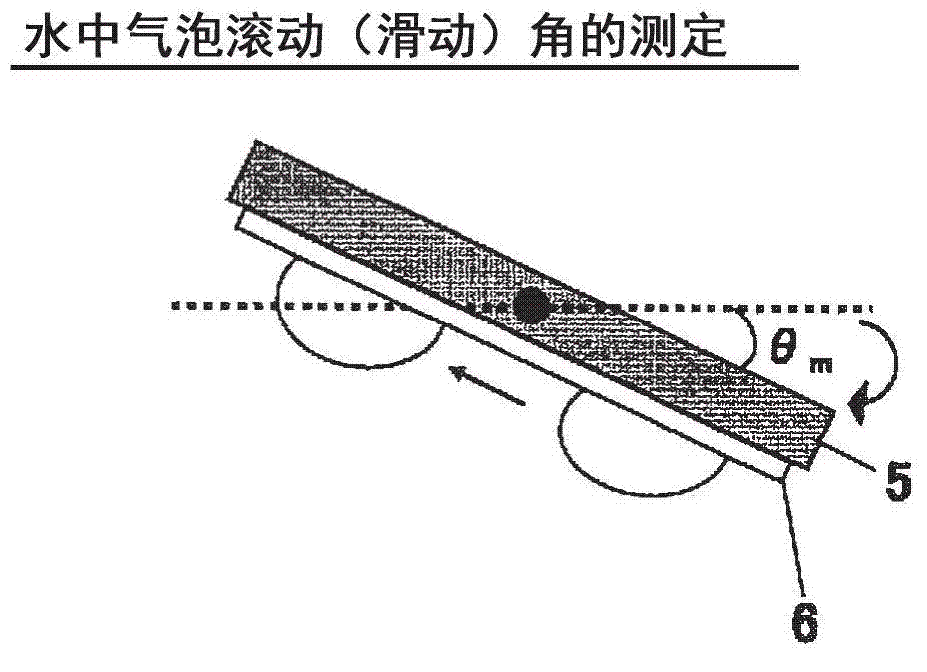

[0364] The coating composition manufactured in the following examples is coated on a rigid polyvinyl chloride plate of 50 × 50 × 2 mm (the maximum height measured according to JIS B 0601 is below 1 μm), so that the dry film thickness reaches 150 μm. Drying was carried out for 5 days, and a test p...

manufacture example 1

[0385] The viscosity at 25°C is 700 mm when both ends of the molecular chain are terminated by silanol groups. 2 900 parts by weight of dimethylpolysiloxane (manufactured by Momentive, XF3905) per s and a specific surface area of 200 m 2 100 parts by weight of surface hydrophobized fumed silica (manufactured by Japan Arrosil Co., Ltd. (Japan Aerosil Corporation), R-972) using a stirring mixer (manufactured by Dalton Corporation (Dalton Corporation) , 5NDMV) were uniformly mixed at 150° C. for 2 hours to obtain basic mixture 1. Base mix 1 has a viscosity of 1530mm 2 / s.

manufacture example 2~4

[0387] In addition to using YF3057 (viscosity: 3000mm 2 / s, manufactured by Momentive), YF3807 (viscosity: 20000mm 2 / s, manufactured by Momentive) and YF3802 (viscosity: 80000mm 2 / s, manufactured by Momentive) as the dimethylpolysiloxane whose molecular chain ends were terminated with silanol groups in Production Example 1, base mixtures 2, 3 and 4 were obtained in the same manner as in Production Example 1. The viscosities of base mixtures 2 and 3 are respectively 8670mm 2 / s, 46000mm 2 / s. Base mix 4 could not be subjected to viscosity measurements due to its high viscosity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com