Lead-acid cell bus-bar pole and method for performing pole group welding of cell by using the same

A lead-acid battery and busbar technology, which is applied in the field of lead-acid battery busbar poles and battery pole group welding, can solve the problems such as the inability to guarantee the conductivity of the plates, the difference in capacity, and the large difference, so as to reduce thermal damage and improve Quality, the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

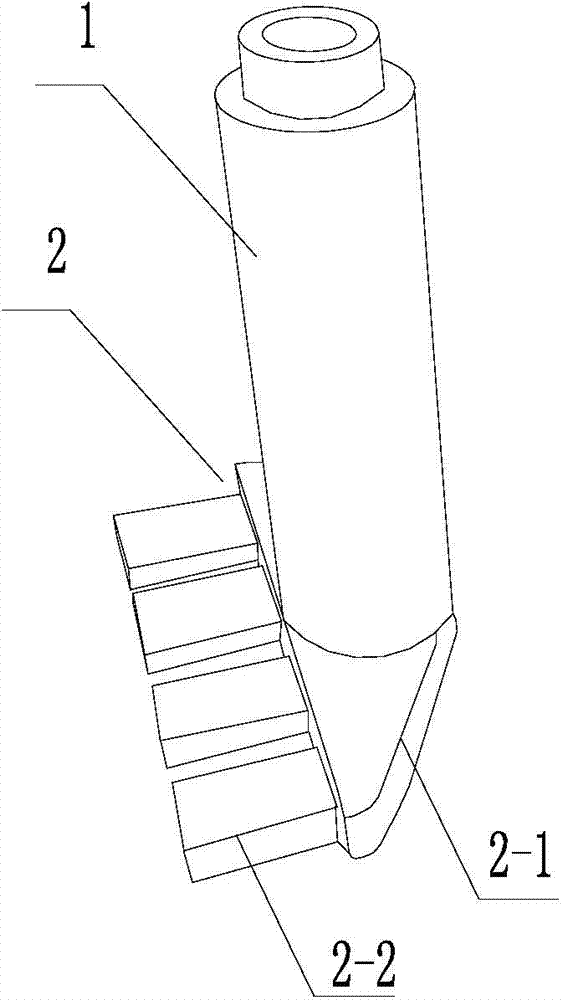

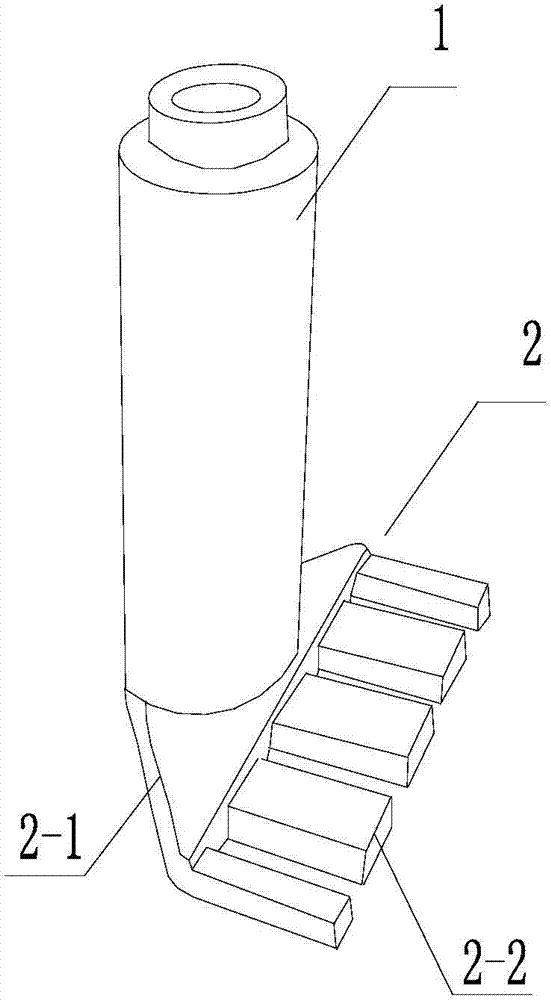

[0034] Example 1: Such as Figure 1-2 As shown, the lead-acid battery bus bar pole of the present invention includes a pole 1 and a bus bar 2 arranged at the bottom of the pole; the bus bar includes a pooling area 2-1 and a welding area 2-2; the pooling area 2 -1 is a tapered surface structure, its necking area is fixedly connected to the pole, and its opening area is connected to the welding zone 2-2; the welding zone 2-2 is a toothed structure at intervals, and the size of the tooth gap is the same as that of the battery pole. The lugs of the plate are adapted; the pole 1 and the bus bar 2 are integrally formed by casting; the material of the welding area is alloy lead; the thickness of the collection area is greater than the thickness of the welding area.

[0035] The method for welding a battery pack using the bus bar pole of the present invention comprises the following steps:

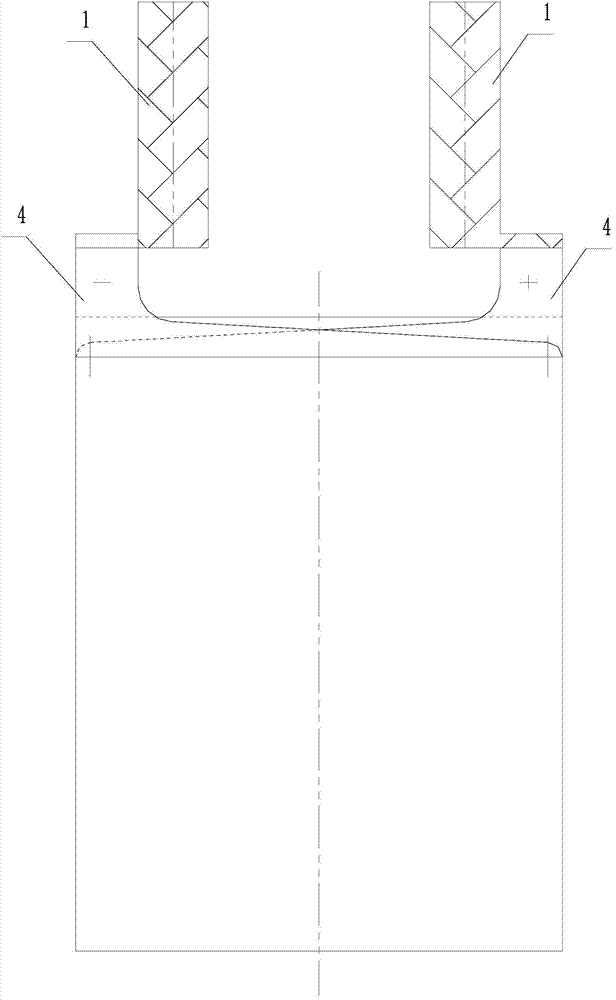

[0036] (1) Stack several pieces of positive and negative plates 4 and separators that need ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com