Detecting method for diamond thickening degree on electroplating abrasive tool surface

A detection method and diamond technology, which are used in measuring devices, material analysis by optical means, instruments, etc., can solve the problems of complex detection methods, high cost and long time of diamond thickening on the surface of abrasive tools, and achieve fast shooting time. , The effect of low equipment requirements and no time consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further elaborated below with reference to the accompanying drawings.

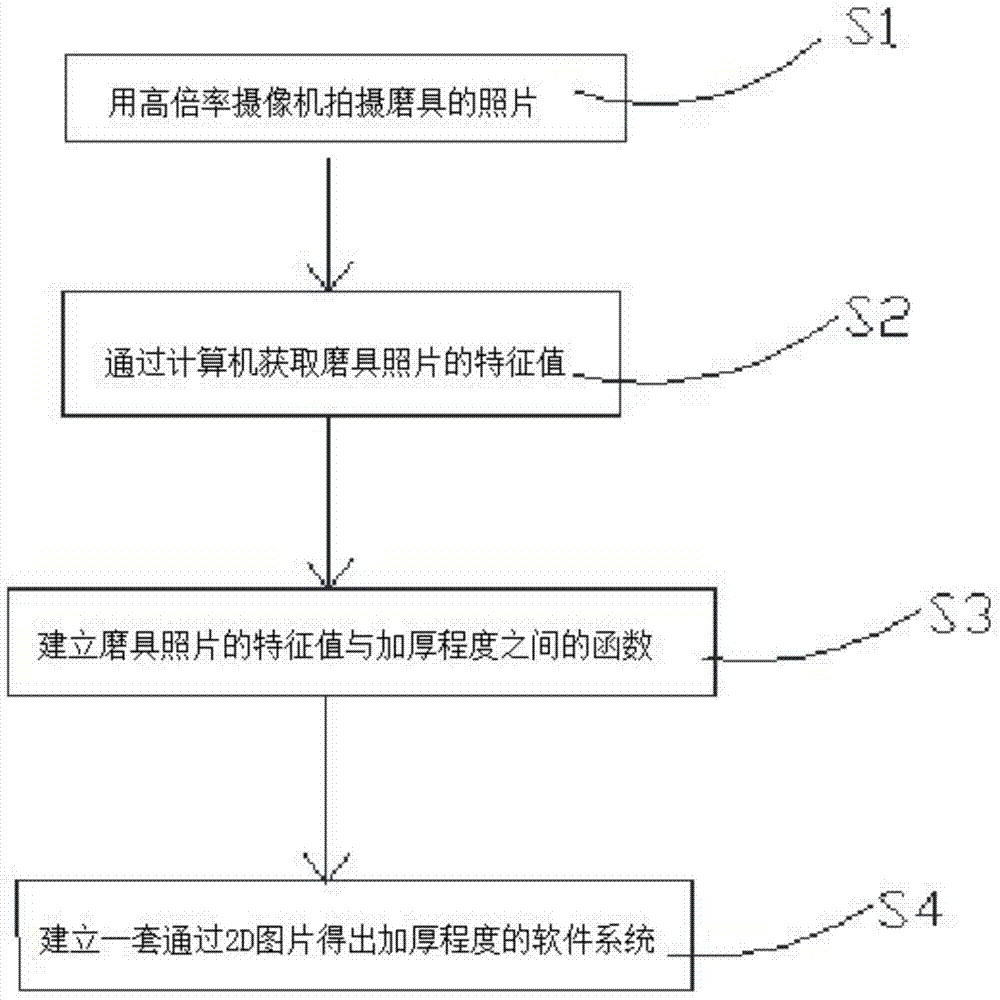

[0016] see figure 1 , a kind of detection method of the diamond thickening degree on the surface of the electroplated abrasive tool of the present invention, it comprises the following steps:

[0017] The first step S1 is to take pictures of the mold with a high-magnification camera. Wherein, the magnification of the camera head of the video camera should be between 50-300 times. Moreover, the photos taken by the camera are common 2D photos.

[0018] The second step S2 is to obtain the characteristic value of the mold photo through the computer. Under the condition of fixed brightness, the higher the average exposed height of the diamond, the stronger the surface optical diffuse reflection, and the lower the average exposed height, the weaker the surface diffuse reflection. The photos taken will also be different, and then by processing the photos, the feature value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com