A new type of pipeline gas automatic water removal device

A gas and pipeline technology, which is applied in the field of new pipeline gas automatic water removal devices, can solve problems such as equipment failures, enterprise economic losses, gas leakage accidents, etc., and achieve the effects of avoiding equipment water inlet failures, reasonable design, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

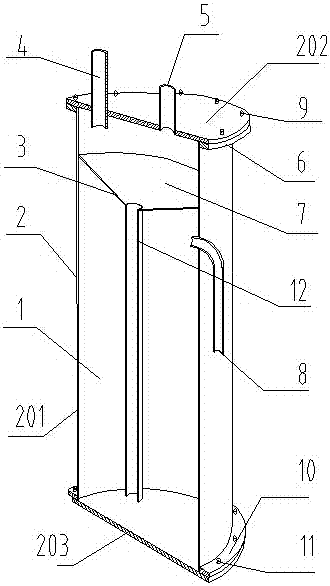

[0017] A new type of pipeline gas automatic water removal device includes a cylindrical water collector 2. The water collector 2 includes a cylindrical body 201, an upper end plate 202 and a lower bottom plate 203 respectively connected to the upper and lower ends of the cylinder 201. The cylinder 201 is provided with a funnel-shaped separator 3, the upper opening periphery of the separator 3 is fully welded and sealed with the inner wall of the cylinder 201, and the separator 3 divides the entire internal space of the cylinder 201 into a vent 7 The venting part 7 and the water storage part 1 are communicated with the water collection pipe 12 at the bottom of the funnel-shaped partition. The upper end plate 202 is provided with a gas inlet and a gas outlet. On the side wall of the cylinder 201, an overflow port is provided in communication with the water storage unit 1. The bottom of the water collection pipe 12 is separated from the water overflow by the accumulation of water ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com