A kind of z-pin reinforced composite wind power blade structure and manufacturing method thereof

A technology for reinforcing composite materials and wind turbine blades, applied in the field of composite material reinforcement, can solve the problems of insufficient performance of the blade shell, weak bearing capacity of open thin-walled beams, poor connection interface performance, etc., and achieve strong designability and easy integration Strong molding and anti-peeling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: A method for manufacturing a Z-pin reinforced composite wind turbine blade structure of the present invention, the method includes the following steps:

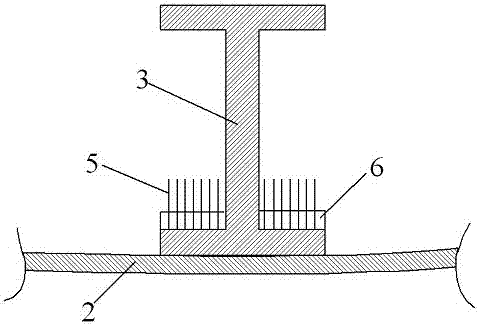

[0037] Step 1: Prepare high-performance Z-pin5 through advanced pultrusion equipment, design Z-pin5 parameters, and then implant Z-pin5 into foam preform 6;

[0038]Step 2: Lay the main girder 3 of the composite material on the special mold according to the designed laying sequence and the number of layers;

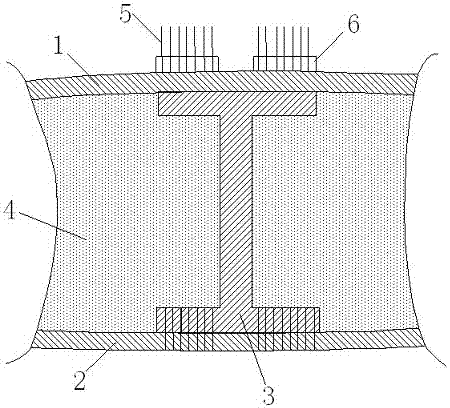

[0039] Step 3: Lay the upper half blade shell 1 in the upper mold of the wind power blade, lay the lower half blade shell 2 in the lower mold of the wind power blade, and then place the above-mentioned main girder 3 on the lower half blade The predetermined position of the casing 2 is such that the lower surface of the lower edge of the main beam 3 is in close contact with the inner wall of the lower half-blade casing 2, thereby forming a lower joint surface;

[0040] Step 4: Bending the above-menti...

Embodiment 2

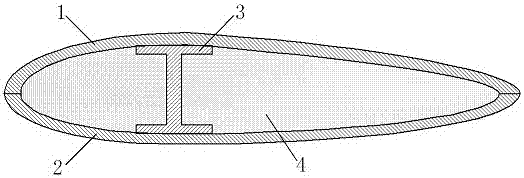

[0050] A Z-pin reinforced composite material wind power blade structure of the present invention includes an upper half blade shell 1 and a lower half blade shell 2 that cooperate to form a blade cavity and are located in the blade cavity for bearing most of the wind power blade. The I-shaped main beam 3 of the bending load, the upper edge of the I-shaped main beam 3 is closely attached to the inner wall of the upper half blade shell 1 to form an upper joint surface, and the lower edge of the I-shaped main beam 3 and the lower The inner walls of the half-blade shell 2 are tightly matched to form a lower joint surface, and the joints of the upper joint surface and the joint of the lower joint surface are implanted with pinning bridges to improve the main beam 1 and the upper half-blade shell. 1 and the Z-pin5 of the connection strength between the I-shaped main beam 3 and the lower half of the blade shell 2, the blade cavity is filled with fillers on both sides of the I-shaped m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com