Method for making continuous carbon fiber cf/paek thermoplastic composite support buckle

A composite material and manufacturing method technology, which can be applied to household appliances, other household appliances, household components, etc., can solve problems such as time-consuming, and achieve the effects of simple implementation, short molding cycle, and high heat resistance temperature.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

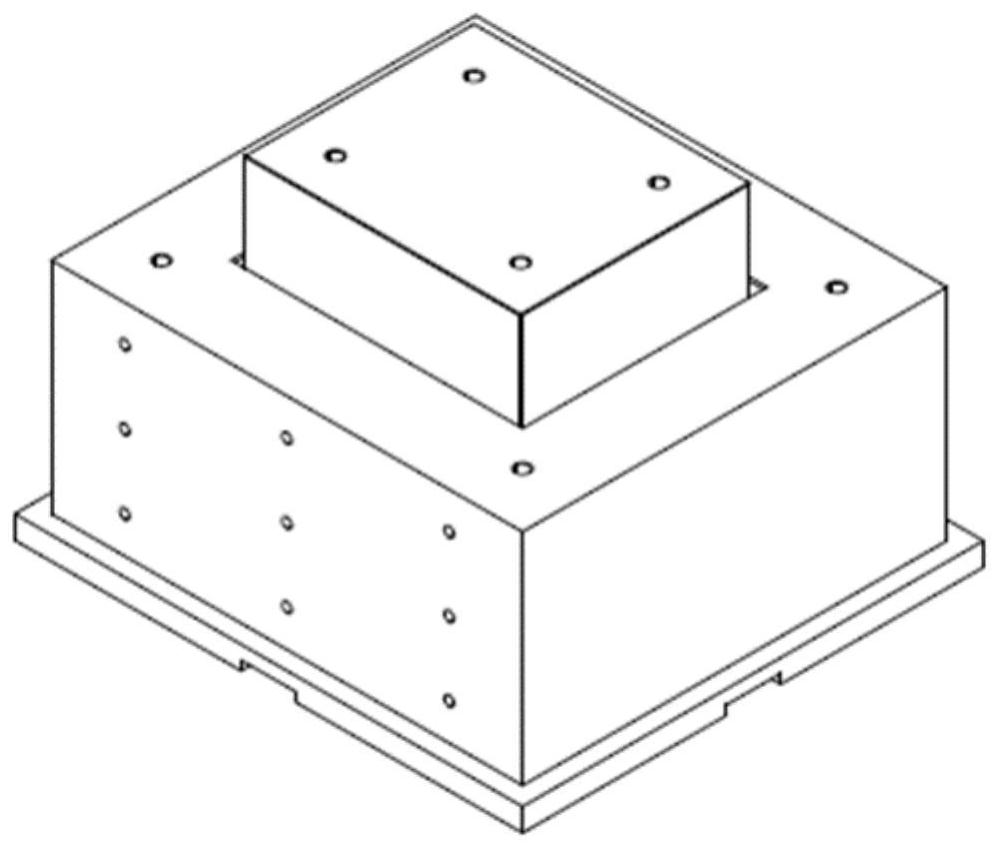

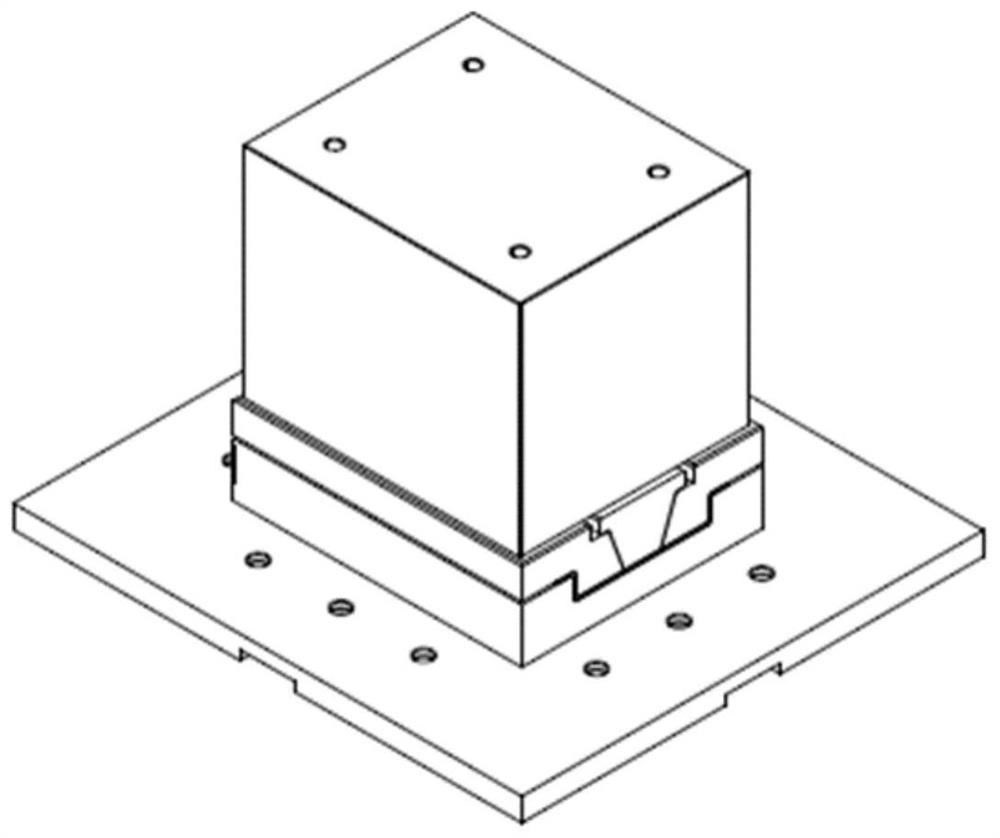

[0082] A continuous carbon fiber CF / PAEK thermoplastic composite material supporting buckle mold is an assembled mold, and the supporting buckle is a 90° bending supporting buckle; as Figure 1-16 As shown, it includes an upper cavity plate and a lower cavity plate 6 for forming an internal cavity and a concave-convex matching structure, a pressure block 1 for contacting with a press and applying pressure to the upper cavity plate; for accommodating the lower Cavity plate 6, upper cavity plate and mold frame frame plate 2 of briquetting block 1 and bottom plate 7 for supporting lower cavity plate 6;

[0083] The lower cavity plate 6, the upper cavity plate and the pressing block 1 are located in the outer frame of the mold in sequence, and the distance between the lower cavity plate 6, the upper cavity plate and the pressing block 1 and the inner wall of the frame plate 2 is 0.02mm~ 1mm; the support buckle 5 made by the mold is located between the lower cavity plate 6 and the ...

Embodiment 2

[0089] A continuous carbon fiber CF / PAEK thermoplastic composite material supporting buckle mold, basically the same as embodiment 1, the only difference is that the longitudinal section of the wedge block 4 is a similar isosceles triangle, and the base angle of the similar isosceles triangle is 60 °. An isosceles triangle and an extension line formed by extending the base of the isosceles triangle to the outside of both sides for a certain length, the extension line and the base are collinear, and the base of the isosceles triangle constitutes a horizontal middle part of the T-shape; etc. The sum of the extension lines formed by the base of the isosceles triangle extending to the outside of both sides for a certain length accounts for 25% of the side length of the base of the isosceles triangle; the length of the base of the isosceles triangle is the length of the T-shape 40%, and the width of the briquetting block 1 is 250% of the length of the base of the isosceles triangle....

Embodiment 3

[0091] A kind of continuous carbon fiber CF / PEEK thermoplastic composite material support buckle that adopts embodiment 1 to make the method for supporting buckle with mold, its concrete steps are as follows:

[0092] (1) Preparation of prepreg: The continuous CF / PEEK prepreg uses continuous carbon fiber CF as the reinforcing phase and PEEK as the matrix phase (the mass content of PEEK resin is 60%). First, cut according to the size of the blank and prepare the material;

[0093] Mold pretreatment: use soft tools to process the mold to remove surface slag, stains or rust spots, etc., then use 2000-grit sandpaper to polish, spray a layer of anti-sticking mold liquid reagent and paste film, and the mold is waiting for assembly ;

[0094] (2) Lay the cut prepregs in the lower cavity 6 of the mold in sequence to complete the preliminary laying. The upper cavity plate is divided into the lower cavity plate and tapped with a rubber cone to ensure that the upper cavity plate is place...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com