Anti-fatigue reinforcing device for concrete filled steel pipe truss structure nodes and construction method thereof

A steel pipe concrete and truss structure technology, applied in truss bridges, bridge reinforcement, erection/assembly of bridges, etc., can solve the problems of stress concentration at the welding seam, large damage to the original steel pipe structure, unfavorable later maintenance, etc., to achieve The effect of simple structure, reduced fatigue stress range and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

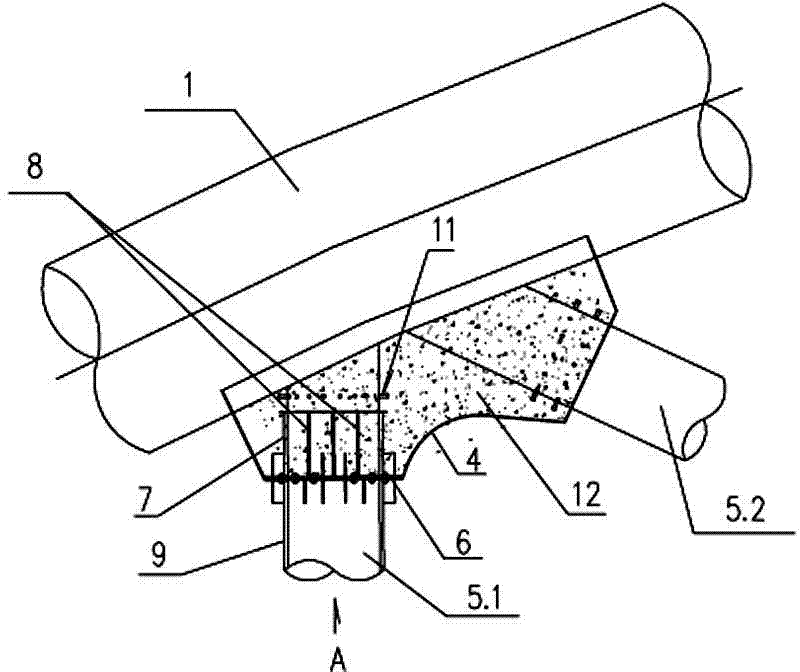

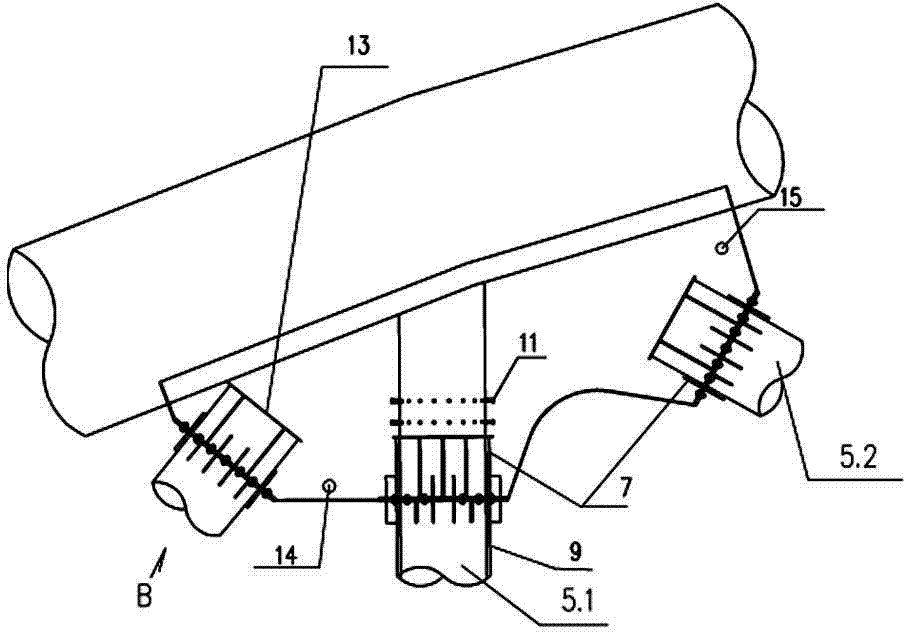

[0027] Such as Figure 1-2 As shown, the anti-fatigue reinforcement device for steel pipe concrete truss structure nodes according to the present invention includes upper and lower guard plates 2,3 welded at the node of the upper chord 1, and the upper and lower guard plates 2,3 are welded on The side sealing plate 4 on the outer edge forms a closed node cavity; the webs (including straight webs 5.1 and oblique webs 5.2) located in the node cavity are sequentially fitted with flanges 6 and reinforcing tubes 7, and the reinforcing tubes 7 The lower end is fixedly connected to the flange 6 attached to the inner surface of the side sealing plate, and a plurality of connecting steel plates 8 are welded between the reinforcing tube 7 and the upper and lower guard plates 2 and 3; located on the web bar 5 outside the node cavity Attached tube 9 is set, and the upper end of the attached tube 9 is fixed on the flange 6 through connecting bolts; the reinforced tube 7 near the flange 6 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com