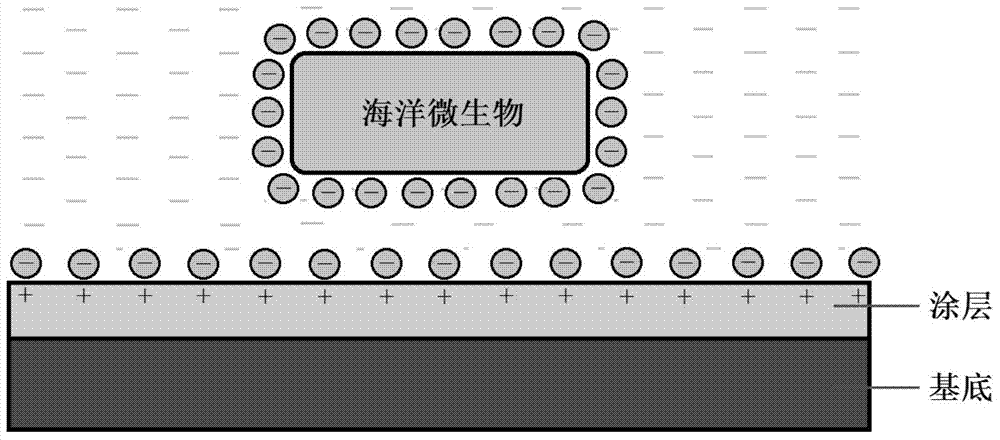

Environment-friendly antifouling damping complex-function coating and preparation method thereof

A composite function, environment-friendly technology, applied in the field of marine engineering and fluid dynamics, can solve the problems of poor anti-fouling and drag reduction effects, and achieve remarkable anti-fouling and drag reduction effects and good engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Mix cationic polyacrylamide (CPAM) with polydimethylsiloxane, acrylic resin and xylene with anti-sedimentation agent and dispersant according to the following parts by weight, and stir evenly to make a coating;

[0031] Cationic polyacrylamide (CPAM) 3.5 parts,

[0032] 5 parts of polydimethylsiloxane,

[0033] Acrylic resin 70 parts,

[0034] 20 parts of xylene,

[0036] Dispersant 0.5 parts.

[0037] Before painting, all pollutants such as oil, dust or rust on the surface of the hull or marine structure should be cleaned up. Then apply (airless spray, high-pressure air spray, brush or roller) antirust paint (such as 616 chlorinated rubber iron red thick paste) and epoxy connecting paint (such as FJ-18) in sequence. After the paint film of the previous paint is cured, the anti-fouling and drag-reducing composite functional coating can be painted. The specific construction process parameters are as follows.

[0038]

[0039] The c...

Embodiment 2

[0041] Blend cationic polyacrylamide (CPAM) with polydimethylsiloxane, fluorocarbon resin and xylene according to the following mass percentages and add anti-sedimentation agent and dispersant, and stir evenly to make a coating;

[0042] Cationic polyacrylamide (CPAM) 5 parts,

[0043] 5.5 parts of polydimethylsiloxane,

[0044] Fluorocarbon resin 73 parts,

[0045] 15 parts of xylene,

[0047] Dispersant 0.5 parts.

[0048] After cleaning the substrate surface, apply anti-rust paint and epoxy connecting paint in sequence. After the paint film of the previous paint is cured, the coating operation of the anti-fouling and drag-reducing composite functional coating is carried out. After the coating is dry, the antifouling and drag reduction performance test is carried out. The results showed that compared with the traditional tin-free self-polishing antifouling coating, the inhibition rate of diatom attachment was increased by 72%, and the num...

Embodiment 3

[0050] Blend cationic polyacrylamide (CPAM) with polydimethylsiloxane, fluorocarbon resin and xylene according to the following mass percentages and add anti-sedimentation agent and dispersant, and stir evenly to make a coating;

[0051] Cationic polyacrylamide (CPAM) 5 parts,

[0052] 5.5 parts of polydimethylsiloxane,

[0053] 30 parts of fluorocarbon resin,

[0054] Acrylic resin 30 parts,

[0055] 16 parts of xylene,

[0056] 0.5 parts of polyamide wax,

[0057] Dispersant 0.3 parts.

[0058]After cleaning the substrate surface, apply anti-rust paint and epoxy connecting paint in sequence. After the paint film of the previous paint is cured, the coating operation of the anti-fouling and drag-reducing composite functional coating is carried out. After the coating is dry, the antifouling and drag reduction performance test is carried out. The results showed that, compared with the traditional tin-free self-polishing antifouling coating, the inhibition rate of diatom a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com