Cationic type antifouling and anti-drag composite functional paint and coating

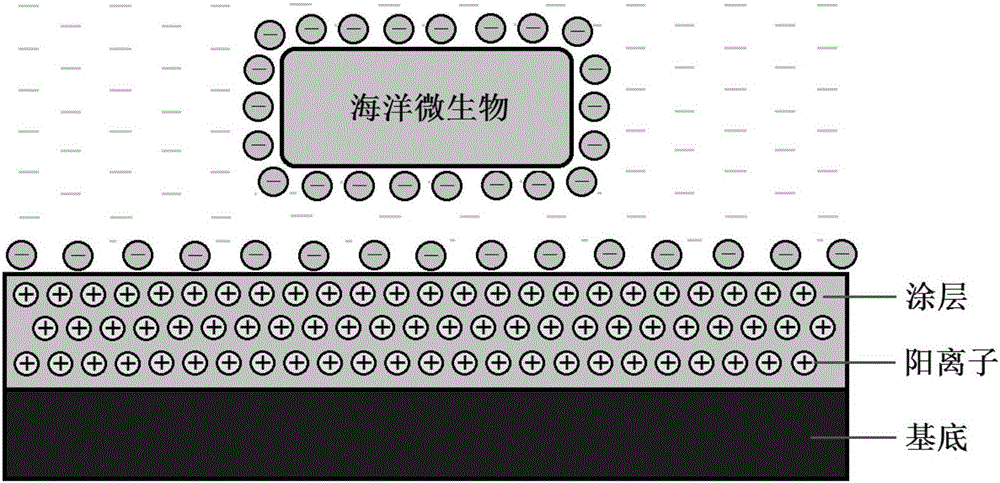

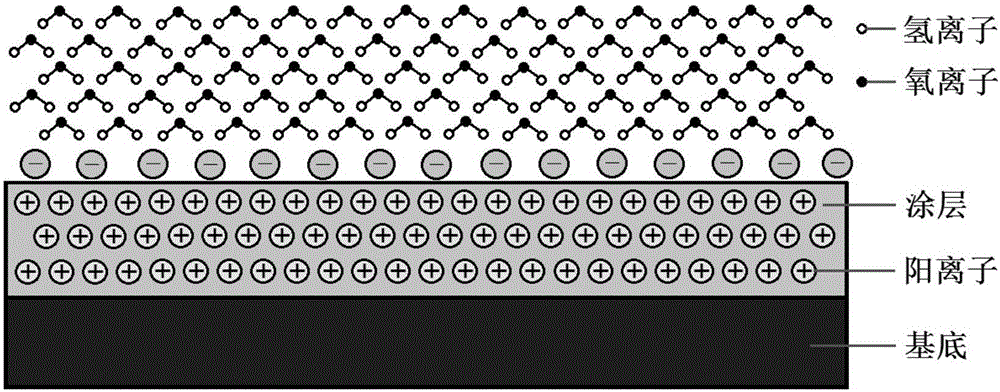

A cationic, composite function technology, applied in the direction of antifouling/underwater coatings, coatings, paints containing biocides, etc., can solve the problems of poor antifouling and drag reduction effects, achieve no toxic side effects, prevent approaching or Effect of adsorption and reduction of surface frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

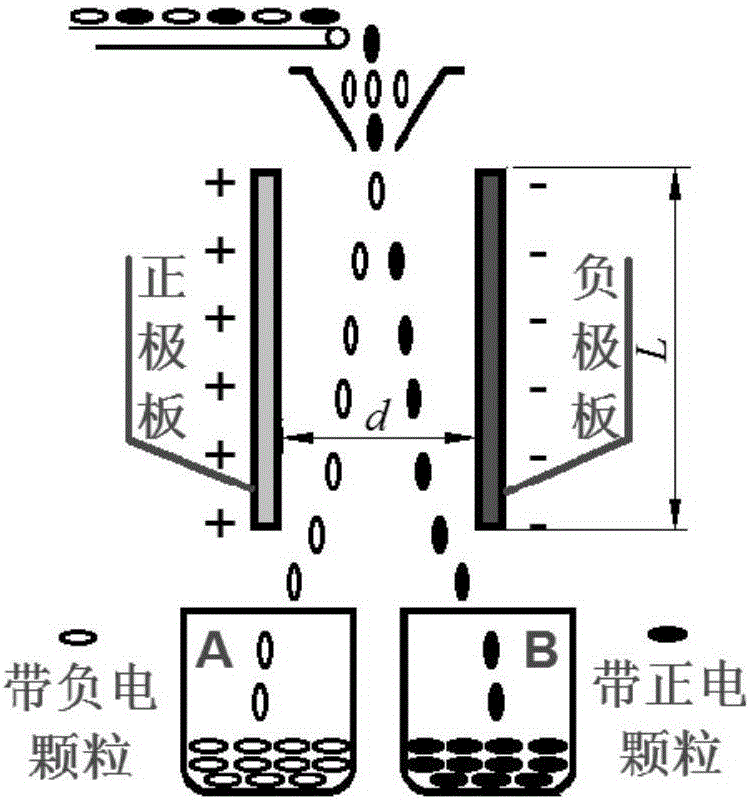

Method used

Image

Examples

Embodiment 1

[0048] The cationic anti-fouling and drag-reducing composite functional coating provided in this embodiment has the following composition:

[0049]

[0050] The anti-fouling and drag-reducing coating prepared by using the above coating is prepared by a preparation method including the following steps:

[0051] Weigh in parts by weight: 20 parts of aluminum powder particles with positive charges on the surface, 50 parts of fluorocarbon resin, 5 parts of isocyanate, 5 parts of xylene, stir and mix evenly to prepare anti-fouling and drag-reducing paint;

[0052] Before painting, clean the oil, dust, rust and other contaminants on the surface of the substrate first, and then apply anti-rust paint (616 chlorinated rubber iron red thick paste type) and epoxy connection on the substrate surface by spraying. Paint (FJ-18), after the paint film of the anti-corrosion paint and epoxy connection paint is cured, the coating operation of the composite functional coating of this embodiment is carri...

Embodiment 2

[0055] The cationic anti-fouling and drag-reducing composite functional coating provided in this embodiment has the following composition:

[0056]

[0057] The anti-fouling and drag-reducing coating prepared by using the above coating is prepared by a preparation method including the following steps:

[0058] Weigh in parts by weight: 10 parts of titanium dioxide particles with positive charges on the surface, 60 parts of fluorocarbon resin, 15 parts of silicone resin, 15 parts of isocyanate, and 20 parts of xylene. Stir and mix evenly to obtain anti-fouling and drag-reducing paint ;

[0059] Before painting, clean the oil, dust, rust and other contaminants on the surface of the substrate first, and then apply anti-rust paint (616 chlorinated rubber iron red thick paste type) and epoxy connection on the substrate surface by spraying. Paint (FJ-18), after the paint film of the anti-corrosion paint and epoxy connecting paint is cured, perform the coating operation of the composite fu...

Embodiment 3

[0062] The cationic anti-fouling and drag-reducing composite functional coating provided in this embodiment has the following composition:

[0063]

[0064] The anti-fouling and drag-reducing coating prepared by using the above-mentioned paint is prepared by a preparation method including the following steps:

[0065] Weigh in parts by weight: 2 parts of silica particles with positive charge on the surface, 73 parts of silicone resin, 10 parts of isocyanate, 5 parts of xylene, 5 parts of butyl acetate, stir and mix evenly to obtain antifouling reduction Barrier coating

[0066] Before painting, clean the oil, dust, rust and other contaminants on the surface of the substrate first, and then apply anti-rust paint (616 chlorinated rubber iron red thick paste type) and epoxy on the surface of the substrate by brushing. Connecting paint (FJ-18). After the paint film of the anti-corrosion paint and epoxy connecting paint is cured, perform the coating operation of the composite functional ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com