Preparation method of ultraviolet rejection attapulgite material

A technology of attapulgite and barrier material, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., to achieve excellent colloidal properties, good shielding properties, and the effect of solving agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

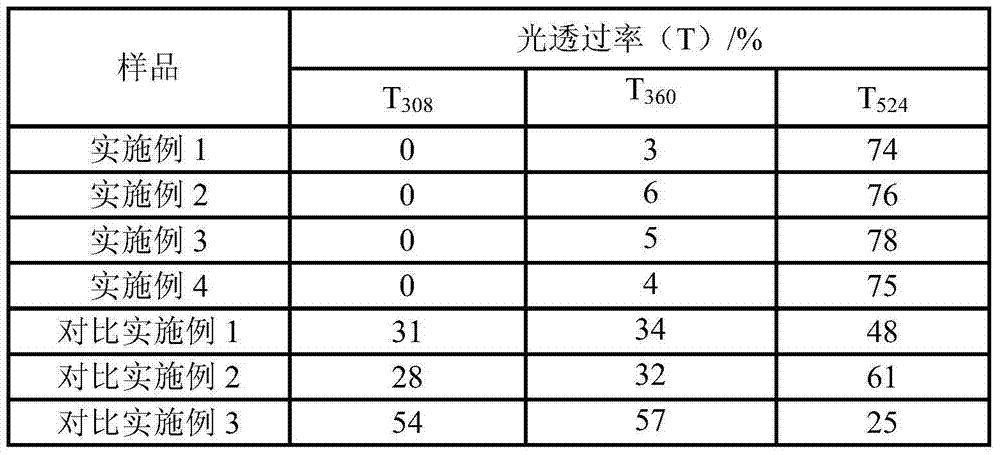

Examples

Embodiment 1

[0018] 1. Control the reaction temperature to 35°C, while stirring, add 2mol L to 0.8 liters -1 Slowly add 1mol·L dropwise to the NaOH aqueous solution -1 0.4 liters of aqueous titanium tetrachloride solution, the pH value of the system after the reaction is 7.0, the titanium dioxide hydrate generated by the reaction is filtered, and washed with deionized water to remove soluble salts to obtain a titanium dioxide hydrate filter cake;

[0019] 2. Add hydrochloric acid solution to 100 grams of attapulgite to prepare a hydrogen ion concentration of 1.5mol L -1 And 1.25 liters of the suspension with attapulgite content of 80 g / L, heat up to 96°C for 3 hours, cool down to 10°C, add the titanium dioxide hydrate filter cake obtained in step 1, heat for 120 hours, add solid partial zinc Sodium acid until the pH of the system is 6.5, continue to react for 2 hours, filter, and wash with deionized water to remove ions in the filter cake;

[0020] 3. The filter cake obtained in step 2 w...

Embodiment 2

[0022] 1. Control the reaction temperature at 25°C, while stirring, add 1mol L to 4 liters -1 Slowly add 0.5mol·L dropwise to the NaOH aqueous solution -1 2 liters of titanium tetrachloride aqueous solution, the pH value of the system after the reaction is 7.0, the titanium dioxide hydrate generated by the reaction is filtered, and washed with deionized water to remove soluble salts, to obtain a titanium dioxide hydrate filter cake;

[0023] 2. Add hydrochloric acid solution to 100 grams of attapulgite to prepare a hydrogen ion concentration of 0.3mol L -1 And 2 liters of the suspension with attapulgite content of 40 g / L, heated up to 88°C for 6 hours, then cooled to 0°C, added the titanium dioxide hydrate filter cake obtained in step 1, and kept the temperature at 0°C for 240 hours, Add sodium metazincate solid until the pH of the system is 7.5, continue to react for 3 hours, filter, and wash with deionized water to remove ions in the filter cake;

[0024] 3. The filter cak...

Embodiment 3

[0026] 1. Control the reaction temperature at 5°C, while stirring, add 3mol·L to 2 liters -1 Slowly add 3mol·L dropwise to the NaOH aqueous solution -1 0.5 liter of titanium tetrachloride aqueous solution, the pH value of the system after the reaction is 7.0, the titanium dioxide hydrate generated by the reaction is filtered, and washed with deionized water to remove soluble salts to obtain a titanium dioxide hydrate filter cake.

[0027] 2. Add hydrochloric acid solution to 120 grams of attapulgite to prepare a hydrogen ion concentration of 1mol L -1 And 1 liter of suspension with a content of attapulgite of 120 g / l, heat up to 100°C for 1 hour, and then cool down to 25°C, add the titanium dioxide hydrate filter cake obtained in step 1, and heat at 25°C for 48 hours, Add sodium metazincate solid until the pH of the system is 6.0, continue to react for 1 hour, filter, and wash with deionized water to remove ions in the filter cake;

[0028] 3. The filter cake obtained in ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com