Precise casting medium temperature modulated wax and preparation method thereof

A technology of precision casting and medium temperature, which is applied in the direction of casting molding equipment, casting molds, manufacturing tools, etc. It can solve the problems of difficult production of high-quality mold materials, and achieve the advantages of improving production efficiency, easy demoulding, and strong dimensional stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

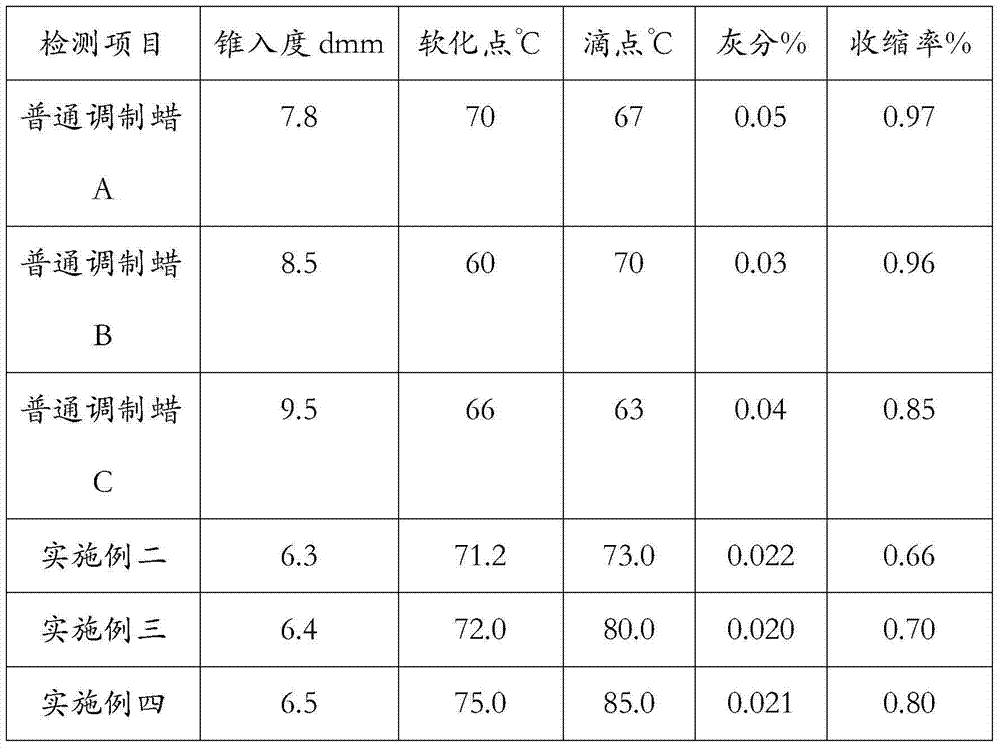

Examples

Embodiment 1

[0031] A medium-temperature modulation wax for precision casting, which includes the following raw materials in parts by mass: 44-46 parts of microcrystalline wax, 2.5-3.5 parts of montan wax, 34-36 parts of rosin resin, ethylene-vinyl acetate copolymer 3.5-4.5 parts of compound, 12-14 parts of pure monomer resin.

[0032] The preparation method of the above-mentioned medium temperature modulation wax for precision casting comprises the following steps:

[0033] (1) Divide the rosin resin into two parts, heat one part at 120° C., keep stirring until melting, then add another part of rosin resin, continue heating, keep stirring until melting, and obtain molten rosin resin A;

[0034] (2) Continue heating the molten rosin resin A obtained in step (1) at 100-120° C. for 1-2 minutes, add montan wax, and keep stirring until completely melted to obtain mixture B;

[0035] (3) Continue heating the mixture B obtained in step (2) at 110-120°C for 1-2 minutes, add ethylene-vinyl acetat...

Embodiment 2

[0041] A medium-temperature modulation wax for precision casting according to Example 1, which includes the following raw materials in parts by mass: 44 parts of microcrystalline wax, 2.5 parts of montan wax, 34 parts of rosin resin, 3.5 parts of ethylene-vinyl acetate copolymer, pure 12 parts of monomer resin.

[0042] The preparation method of the above-mentioned medium temperature modulation wax for precision casting comprises the following steps:

[0043] (1) Divide the rosin resin into two parts, heat one part at 120° C., keep stirring until melting, then add another part of rosin resin, continue heating, keep stirring until melting, and obtain molten rosin resin A;

[0044] (2) Continue heating the molten rosin resin A obtained in step (1) at 100° C. for 1 minute, add montan wax, and keep stirring until completely melted to obtain mixture B;

[0045] (3) Continue heating the mixture B obtained in step (2) at 110° C. for 1 minute, add ethylene-vinyl acetate copolymer, an...

Embodiment 3

[0051]A medium-temperature modulation wax for precision casting according to Embodiment 1, which includes the following raw materials in parts by mass: 46 parts of microcrystalline wax, 3.5 parts of montan wax, 36 parts of rosin resin, 4.5 parts of ethylene-vinyl acetate copolymer, pure 14 parts of monomer resin.

[0052] The preparation method of the above-mentioned medium temperature modulation wax for precision casting comprises the following steps:

[0053] (1) Divide the rosin resin into two parts, heat one part at 120° C., keep stirring until melting, then add another part of rosin resin, continue heating, keep stirring until melting, and obtain molten rosin resin A;

[0054] (2) Continue heating the molten rosin resin A obtained in step (1) at 120° C. for 2 minutes, add montan wax, and keep stirring until completely melted to obtain mixture B;

[0055] (3) Continue heating the mixture B obtained in step (2) at 120° C. for 2 minutes, add ethylene-vinyl acetate copolymer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| drop melting point | aaaaa | aaaaa |

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com