Composite titanium dioxide nano-sheet photocatalyst, preparation method and applications thereof

A technology of titanium dioxide and photocatalyst, applied in the field of photocatalysis, can solve the problems of two-dimensional nanostructure research, the efficiency is only 80%, and achieve the effect of simple preparation method, improved efficiency and reduced energy cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

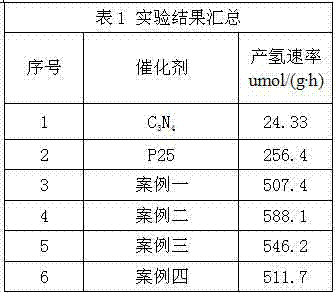

Examples

Embodiment example 1

[0033] Configure P with a mass ratio of 1:14 123 and absolute ethanol mixed solution, the obtained mixed solution was added into the concentrated hydrochloric acid and isopropyl titanate mixed solution with a volume ratio of 1:3, and stirred for 30 min. Take the above solution and ethylene glycol with a volume ratio of 1:8, mix them evenly and add them into an autoclave, and react for 20 hours at 120°C, then wash the solid product in the autoclave with absolute ethanol for 4 times, and put it in a vacuum drying oven for 80 °C, dried for 3 hours to obtain white titanium dioxide nanosheets. 100 mg of titanium dioxide nanosheets were calcined in a tube furnace at 500° C. for 2 h, and then cooled down to room temperature naturally to obtain a white solid.

[0034] Weigh titanium dioxide nanosheets and melamine with a mass ratio of 1:2 and dissolve them in water, mix the mixed solution with 15 mg / L carbon quantum dot solution at a volume ratio of 3:1, stir at 69~70°C for 6...

Embodiment example 2

[0036] Configure P with a mass ratio of 1:15 123 and absolute ethanol mixed solution, the obtained mixed solution was added into the concentrated hydrochloric acid and isopropyl titanate mixed solution with a volume ratio of 1:3, and stirred for 30 min. Take the above solution and ethylene glycol with a volume ratio of 1:8, mix them evenly and add them to the autoclave, and react for 20 hours at 120 °C, then wash the solid product in the autoclave with absolute ethanol for 3 times, and put it in a vacuum drying oven for 80 °C, dried for 3 hours to obtain white titanium dioxide nanosheets. 100 mg of titanium dioxide nanosheets were calcined in a tube furnace at 500° C. for 2 h, and then cooled down to room temperature naturally to obtain a white solid.

[0037] Weigh titanium dioxide nanosheets and melamine with a mass ratio of 1:4 and dissolve them in water, mix the mixed solution with 12mg / L carbon quantum dot solution at a volume ratio of 3:1, stir at 69~70°C for 6h...

Embodiment example 3

[0039] Configure P with a mass ratio of 1:15 123 and absolute ethanol mixed solution, the obtained mixed solution was added into the concentrated hydrochloric acid and isopropyl titanate mixed solution with a volume ratio of 1:4, and stirred for 30 min. Take the above solution and ethylene glycol with a volume ratio of 1:10, mix them evenly and add them into the autoclave, react at 120°C for 20h, then wash the solid product in the autoclave with absolute ethanol for 3 times, and put it in a vacuum drying oven for 80 °C, dried for 3 hours to obtain white titanium dioxide nanosheets. 100 mg of titanium dioxide nanosheets were calcined in a tube furnace at 500° C. for 2 h, and then cooled down to room temperature naturally to obtain a white solid.

[0040]Weigh titanium dioxide nanosheets and melamine with a mass ratio of 1:8 and dissolve them in water, mix the mixed solution with 13mg / L carbon quantum dot solution at a volume ratio of 3:1, stir at 65~69°C for 6h, and then...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com