Novel carbonylation reactor for process of producing glycol through synthesis gas

A reactor and ethylene glycol technology, applied in the field of new carbonylation reactors, can solve the problems of small catalyst temperature resistance range, high heat transfer efficiency, and increased thermal resistance of metal plates, and achieve completely uniform static pressure difference distribution and high boiling Effect of heat transfer coefficient and renewal speed acceleration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

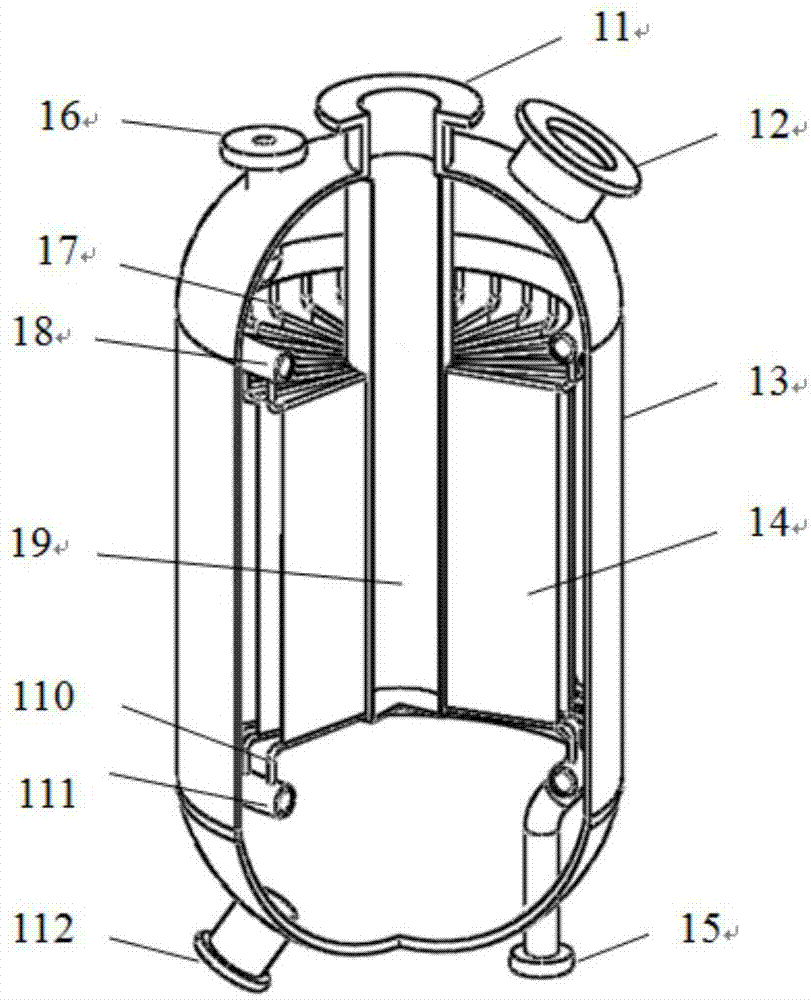

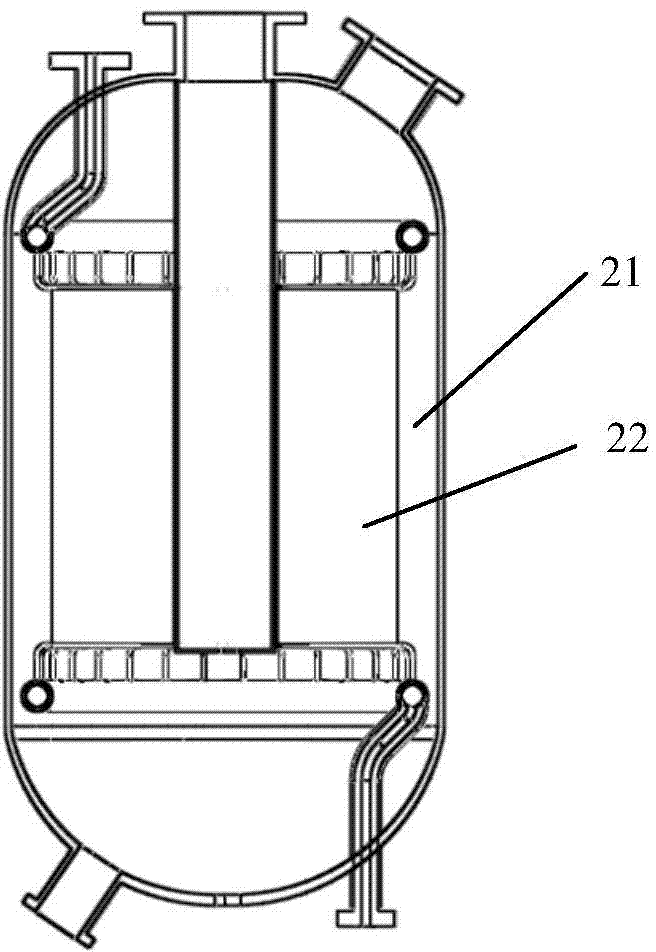

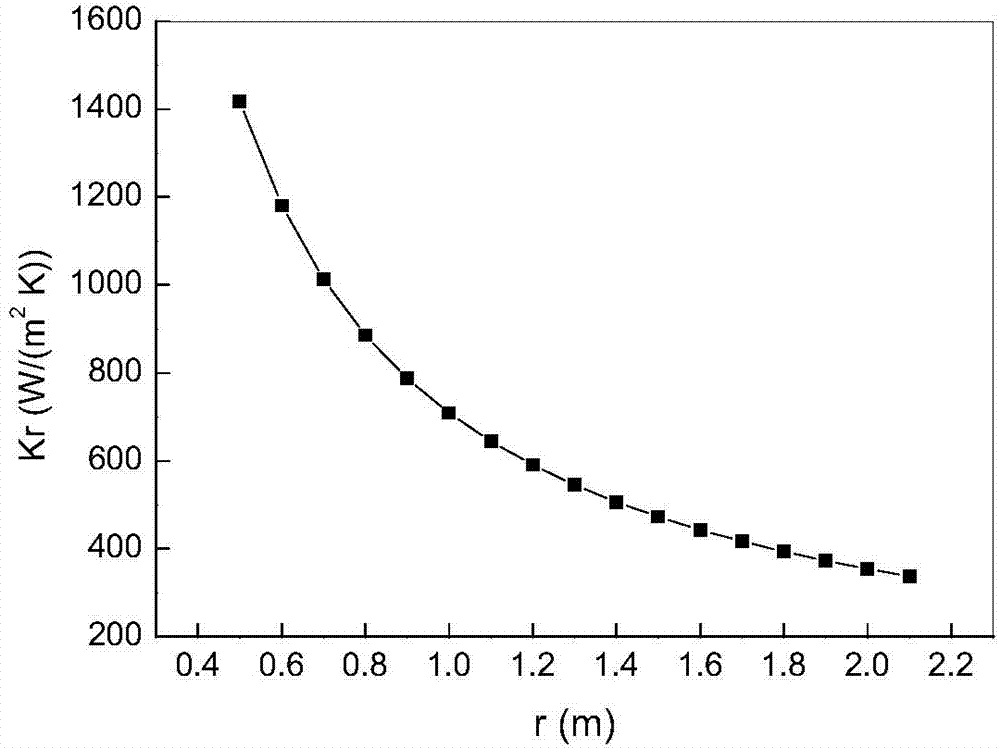

[0042] The present invention is a novel carbonylation reactor for synthesis gas to ethylene glycol process, the structure is as follows figure 1 As shown, the reactor is a radial reactor, including a reactor shell 13, a heat exchange assembly, a manifold 19, a header 21 and a catalyst 22, the manifold 19 is located at the center of the reactor, and the catalyst 22 is arranged in the heat exchange assembly , the reactor shell 13 includes a cylinder, an upper head, a lower head, a reaction gas inlet 11, a reaction gas outlet 12, a cooling medium inlet 15, a cooling medium outlet 16, and a catalyst discharge port 112; the reaction gas inlet 11 and the reaction gas The outlets 12 are all arranged on the upper head, and the reaction gas enters the reactor from the reaction gas inlet 11 on the upper head, and then flows down along the central shunt pipe 19, and reacts radially through the catalyst bed, and the reaction product gas enters the header 21 , and flow upward along the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com