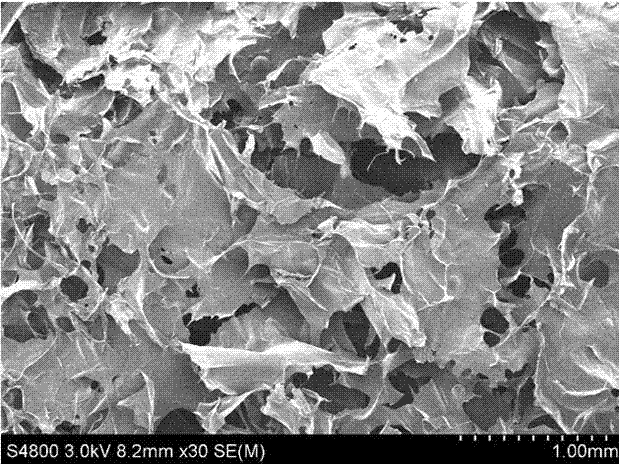

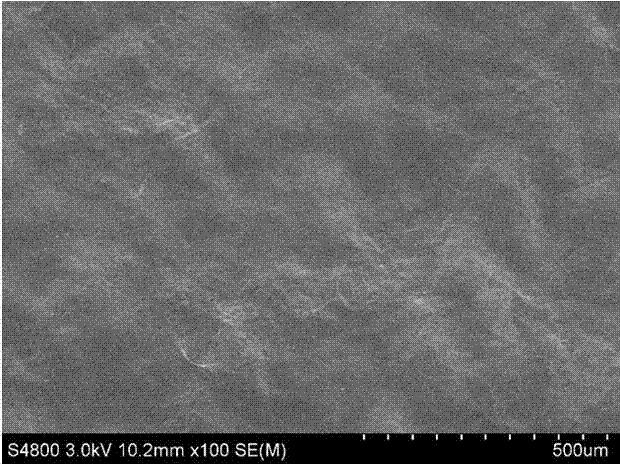

Preparation method for chitosan-based biomimetic membrane material with asymmetric structure

An asymmetric structure, chitosan technology, used in medical science, surgery and other directions, can solve the problems of fast degradation, fin shedding, allergic reactions, etc., achieve controllable degradation, good bone induction regeneration performance, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] 1) Disperse chitosan powder in 2% acetic acid aqueous solution, stir until completely dissolved, and prepare 2 wt % chitosan solution, then add anhydrous methanol and acetic anhydride to it to make anhydrous methanol The volume ratio with water is 4:3, the mass ratio of chitosan and acetic anhydride is 3.5, after stirring evenly, let it stand for reaction for 1.5h to obtain an acid-soluble chitosan solution;

[0018] 2) Centrifuge the acid-soluble chitosan solution in step 1) at a speed of 5000rpm for 10min, remove the precipitate, drop into it a NaOH aqueous solution with a mass fraction of 5% under stirring conditions until the solution is alkaline, filter and use three Wash the filtrate with distilled water until the washing liquid is neutral to obtain chitosan microgel;

[0019] 3) Add the chitosan microgel in step 2) into the glycerol aqueous solution with a volume fraction of 10%, stir for 30 minutes to obtain a mixed solution, inject the mixed solution into a mol...

Embodiment 2

[0023] 1) Disperse chitosan powder in 2% acetic acid aqueous solution, stir until completely dissolved, and prepare 2.5 wt % chitosan solution, then add anhydrous methanol and acetic anhydride to it to make anhydrous methanol The volume ratio with water is 5:3, the mass ratio of chitosan and acetic anhydride is 3.8, after stirring evenly, let stand for reaction 2h, obtain acid-soluble chitosan solution;

[0024] 2) Centrifuge the acid-soluble chitosan solution in step 1) at a speed of 6000rpm for 12min, remove the precipitate, drop into it a KOH aqueous solution with a mass fraction of 5% under stirring conditions until the solution is alkaline, filter and use three Wash the filtrate with distilled water until the washing liquid is neutral to obtain chitosan microgel;

[0025] 3) Add the chitosan microgel in step 2) into the glycerol aqueous solution with a volume fraction of 12%, stir for 30 minutes to obtain a mixed solution, inject the mixed solution into a mold, and let it...

Embodiment 3

[0029] 1) Disperse chitosan powder in 2% acetic acid aqueous solution, stir until completely dissolved, and prepare 3 wt % chitosan solution, then add anhydrous methanol and acetic anhydride to it to make anhydrous methanol The volume ratio with water is 4:3, the mass ratio of chitosan and acetic anhydride is 4.0, after stirring evenly, let it stand for reaction for 2h to obtain an acid-soluble chitosan solution;

[0030] 2) Centrifuge the acid-soluble chitosan solution in step 1) at a speed of 6500rpm for 15min, remove the precipitate, drop into it a KOH aqueous solution with a mass fraction of 5% under stirring conditions until the solution is alkaline, filter and use three Wash the filtrate with distilled water until the washing liquid is neutral to obtain chitosan microgel;

[0031] 3) Add the chitosan microgel in step 2) into the glycerol aqueous solution with a volume fraction of 15%, stir for 35 minutes to obtain a mixed solution, inject the mixed solution into a mold, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com