Medical device and manufacture thereof

A technology of medical devices and coatings, applied in pharmaceutical formulations, medical science, prostheses, etc., which can solve problems such as delayed corrosion or biodegradation, loss of mechanical stability, and complex manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

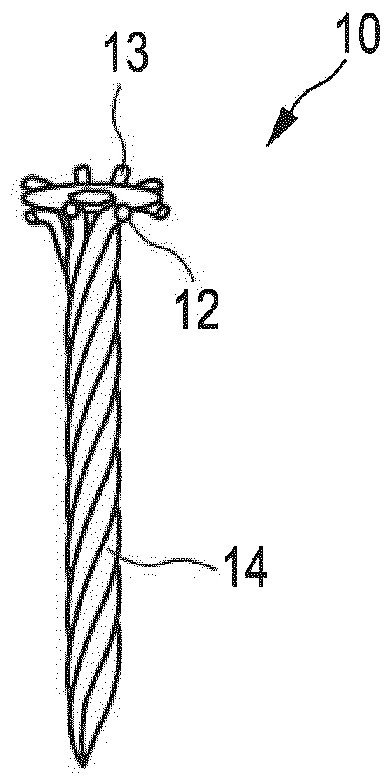

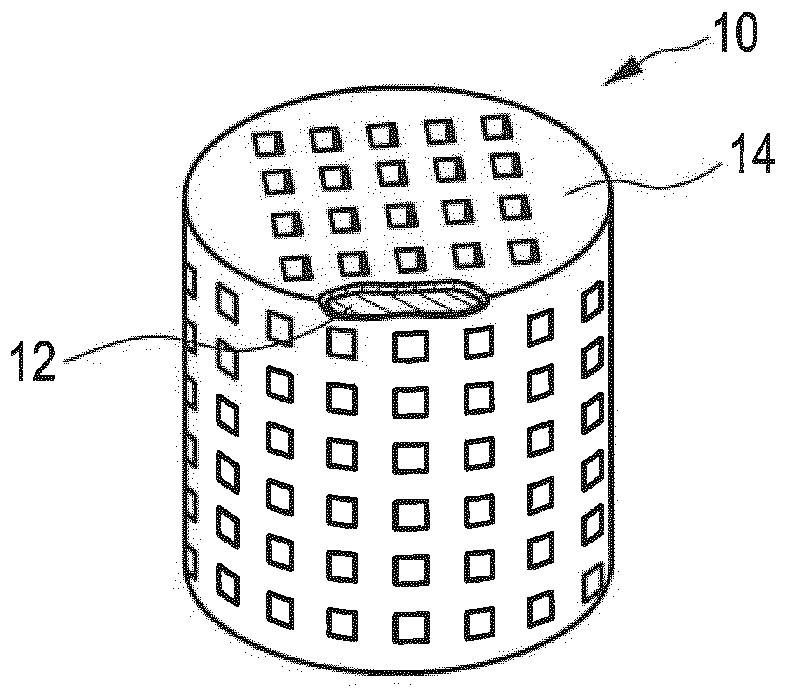

[0123] figure 1 An embodiment of the medical device 10 according to the present invention is shown schematically. The medical device 10 includes a device body 12. The device body 12 preferably includes or comprises a material that is easy to corrode or biodegradable, such as magnesium or magnesium alloy. Further, the medical device 10 includes a worm coating 14. The apparatus body 12 covers the insect rubber coating 14 only or completely (as shown). Preferably, the insect coating 14 has a thickness from 0.1 μm to 20 μm.

[0124] By way of example, the medical device 10 can be in the form of a backbone for a bone.

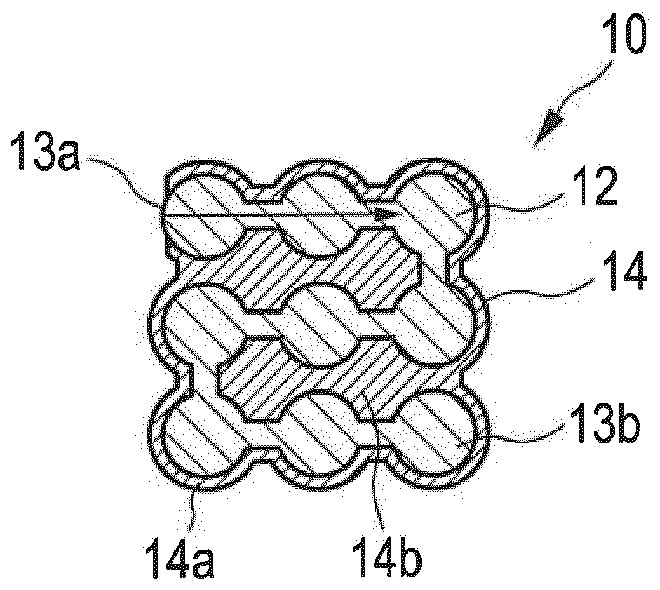

[0125] figure 2 A cross-sectional view of the strut 11 of the medical device 10 of the present invention is shown schematically. The pillar 11 covers a insect rubber coating 14. The pillar 11 preferably includes or comprising a material that is easy to corrode or biodegradable, such as magnesium or magnesium alloy (eg, "WE43" or "resoloy").

[0126] The strut 11 can c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com