A kind of Xiaoai plain tablet and preparation method thereof

A technology for Xiaoai flat tablets with average particle size, which is applied in pharmaceutical formulas, medical preparations containing active ingredients, antineoplastic drugs, etc., and can solve the problems of poor patient compliance, poor compressibility, uneven tablet surface, Achieve the effects of easy forming and stability, smooth and beautiful surface, and stable tablet weight difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Embodiment 1 Preparation of Xiaoai Plain Tablets of the present invention

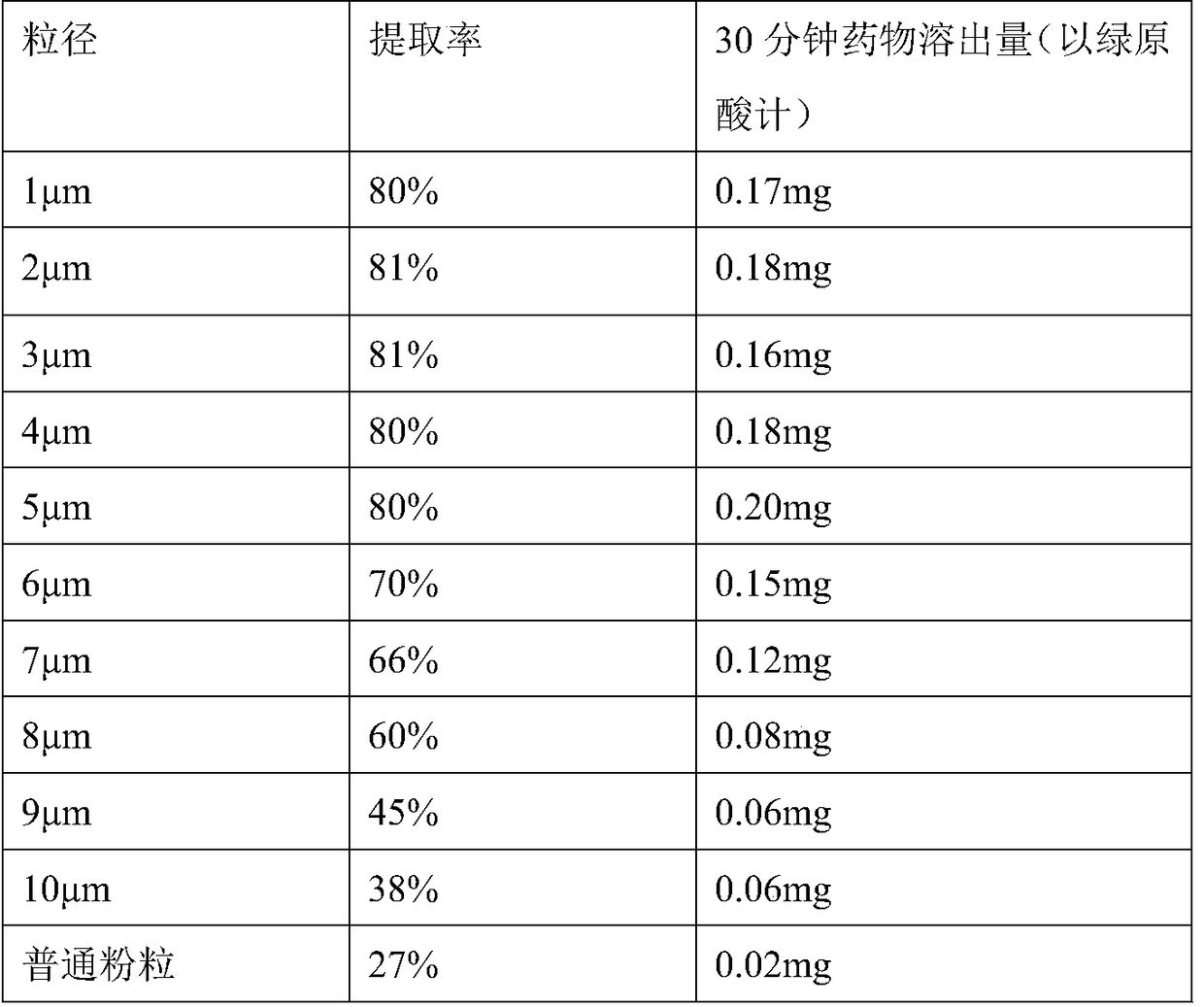

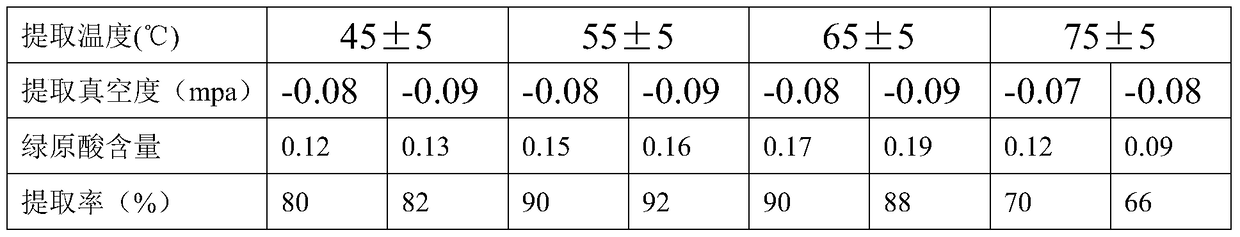

[0021] Take 1500g of Tengguan vine, soak it in water for 12 hours, and extract it under reduced pressure for 3 times. The vacuum degree of extraction is -0.08~-0.09mpa, and the extraction temperature is controlled at 65±5°C. The extract is ultrafinely pulverized, crushed to an average particle size of 5 μm, mixed with 20 g of starch for 10 minutes, and added with a small amount of water to continue mixing for 5 minutes. Granulate with a twin-screw extruder granulator (Changzhou Huaou Drying and Granulating Equipment Co., Ltd.: SET series twin-screw extruder granulator), and press into 1000 tablets to get final product.

Embodiment 2

[0022] Embodiment 2 Preparation of Xiaoai Plain Tablets of the present invention

[0023] Take 1500g of Tengguan vine, soak it in water for 12 hours, and extract it under reduced pressure for 3 times. The extraction vacuum is -0.08~-0.09mpa; the extraction temperature is controlled at 65±5°C, the extract is ultra-micronized, crushed to an average particle size of 3 μm, mixed with 15g of starch for 10 minutes, and added with a small amount of water to continue mixing for 5 minutes. Granulate with a twin-screw extrusion granulator, press into 1000 tablets, and coat with sugar.

Embodiment 3

[0024] Embodiment 3 Preparation of Xiaoai Plain Tablets of the present invention

[0025] Take 1500g of Tengguan vine, soak it in water for 12 hours, and extract it under reduced pressure for 3 times. The extraction vacuum is -0.08~-0.09mpa; the extraction temperature is controlled at 65±5°C. The extract was ultramicronized, pulverized to an average particle size of 8 μm, mixed with 30 g of starch for 10 minutes, and added with 12.5% water to continue mixing for 5 minutes. Granulate with a twin-screw extrusion granulator, press into 1000 tablets, and coat with a film.

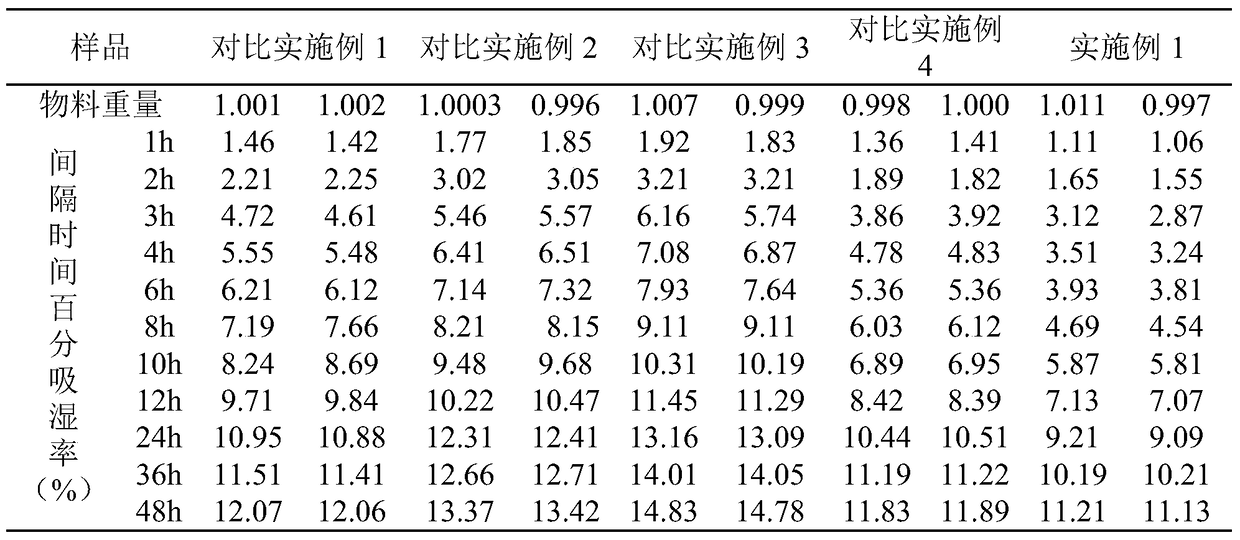

[0026] The beneficial effect of the present invention is further illustrated by comparative experiments below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com