Hyaluronic acid-chitosan microsphere carrying epidermal growth factor and preparation method and application of hyaluronic acid-chitosan microsphere

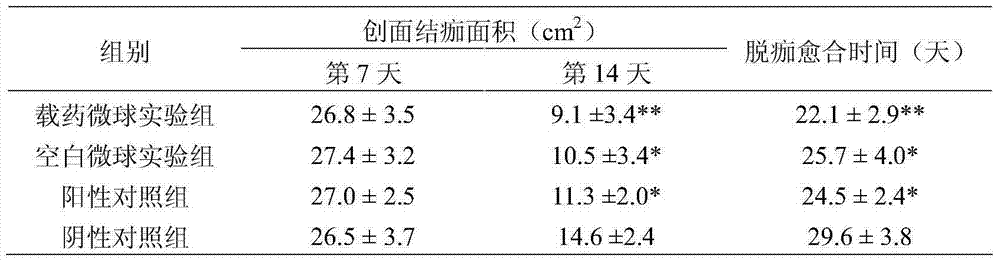

A technology of epidermal growth factor and chitosan microspheres, which can be applied to medical preparations without active ingredients, medical preparations containing active ingredients, skin diseases, etc. It can protect the wound surface, improve the quality of healing, and speed up the healing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of hyaluronic acid-chitosan microspheres loaded with epidermal growth factor

[0036] (1) Hyaluronic acid (average relative molecular mass 0.12×10 6 ) 0.2g, sodium tripolyphosphate 0.05g, and epidermal growth factor 0.1g were dissolved in 1000ml of purified water.

[0037] (2) Chitosan (average relative molecular mass 0.08×10 6 , deacetylation degree 88%) 1.2g dissolved in 1000ml purified water.

[0038] (3) Add the solution obtained in step (1) to the solution obtained in step (2) and stir and mix continuously with an electromagnetic stirrer, the addition speed is 50ml / min, the addition time is 20min, the stirring speed is 300 rpm, and the stirring time is 30min , to obtain a suspension containing hyaluronic acid-chitosan microspheres.

[0039] (4) Centrifuge the suspension obtained in the above step (3) with a centrifugal force of 10000g and a centrifugation time of 30min; discard the supernatant and collect the precipitate.

[0040] (5) Add the precip...

Embodiment 2

[0044] Preparation of hyaluronic acid-chitosan microspheres loaded with epidermal growth factor

[0045] (1) Hyaluronic acid (average relative molecular mass: 0.06×10 6 ) 0.4g, sodium tripolyphosphate 0.1g, and epidermal growth factor 0.1g were dissolved in 1000ml of purified water.

[0046] (2) Chitosan (average relative molecular mass 0.08×10 6 , deacetylation degree 88%) 2g dissolved in 1000ml purified water.

[0047] (3) Add the solution obtained in step (1) to the solution obtained in step (2) and stir and mix continuously with an electromagnetic stirrer, the addition speed is 100ml / min, the addition time is 10min, the stirring speed is 600 rpm, and the stirring time is 30min , to obtain a suspension containing hyaluronic acid-chitosan microspheres.

[0048] (4) Centrifuge the suspension obtained in the above step (3) with a centrifugal force of 10000g and a centrifugation time of 30min; discard the supernatant and collect the precipitate.

[0049] (5) Add the precipita...

Embodiment 3

[0053] Preparation of Film Containing Epidermal Growth Factor Microspheres

[0054] A. Take 120g of polyvinyl alcohol (model 2699) and add it to 1000ml of purified water to dissolve, take 10g of soluble starch, add it and stir to dissolve. Heat the above solution to 70°C-80°C, add 20g of glycerin, 10g of Tween, and 8g of simethicone oil respectively and stir, leave it at room temperature to cool down, filter, add 2g of hyaluronic acid-chitosan microbe loaded with epidermal growth factor Ball, spare.

[0055] B. Prepare an aqueous solution of 10% polyvinyl alcohol for later use.

[0056] C. Prepare 4% nitrocellulose alcohol-ether mixture (alcohol-ether volume ratio 1:1) for later use.

[0057] D. Prepare 4% collagen in glacial acetic acid solution for later use.

[0058] Apply liquid B evenly on a glass plate, dry it in vacuum at 40°C, then apply liquid C, liquid A, and liquid D in sequence, dry it in vacuum at 40°C, and divide it into small pieces to obtain the product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com