Highly-efficient organic electroluminescent device based on fluorescence doped luminescent layer

A technology for electroluminescent devices and light-emitting layers, which can be used in electro-solid devices, electrical components, semiconductor devices, etc., and can solve problems such as low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

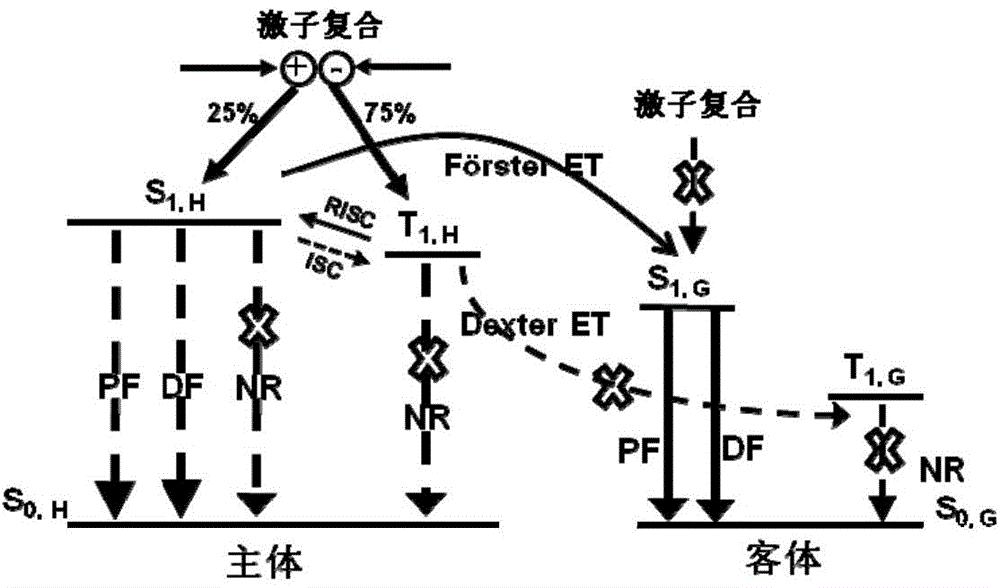

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

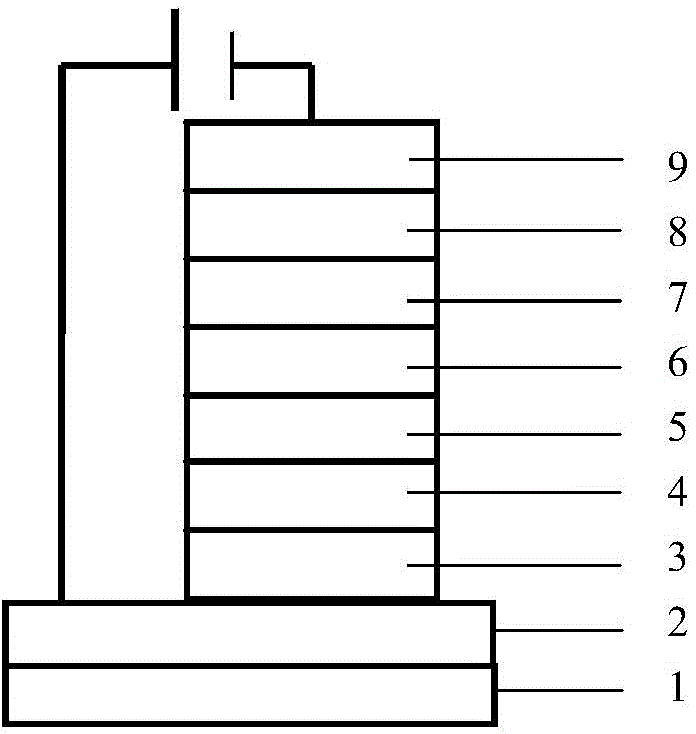

[0035] Example 1: Device [ITO / NPB / mCP / 4CzIPN:0.5%DFDB-QA / BCP / BePP 2 / LiF / Al]

[0036] The 15mm×15mm×1mm thick ITO conductive glass substrate was ultrasonically cleaned with ITO cleaning solution for 5 minutes, deionized water for 5 minutes, acetone for 20 minutes, and isopropanol for 20 minutes. After drying, plasma (plasma) treatment for 5 minutes. In high vacuum 5 x 10 -5 The hole transport layer NPB was sequentially deposited under Pa with a thickness of 35nm; the first exciton blocking layer mCP was deposited with a thickness of 5nm; the light emitting layer was deposited by dual-source co-evaporation, in which the host material was 4CzIPN and the guest doping material was DFDB-QA , the doping concentration is 0.5% (weight percentage), the thickness is 30nm; the second exciton blocking layer BCP, the thickness is 5nm; the electron transport layer BePP 2 , with a thickness of 40nm. Then deposit the electron injection layer LiF with a thickness of 1 nm; the metal cathode...

Embodiment 2

[0038] Example 2: Device [ITO / NPB / mCP / 4CzIPN:0.5%TCF 3 DB-QA / BCP / BePP 2 / LiF / Al]

[0039] The 15mm×15mm×1mm thick ITO conductive glass substrate was ultrasonically cleaned with ITO cleaning solution for 5 minutes, deionized water for 5 minutes, acetone for 20 minutes, and isopropanol for 20 minutes. After drying, plasma treatment for 5 minutes. In high vacuum 5 x 10 -5 The hole transport layer NPB was sequentially deposited under Pa with a thickness of 35nm; the first exciton blocking layer mCP was deposited with a thickness of 5nm; the light-emitting layer was deposited by double-source co-evaporation, in which the host material was 4CzIPN and the guest dopant material was TCF 3 DB-QA, the doping concentration is 0.5% (weight percentage), the thickness is 30nm; the second exciton blocking layer BCP, the thickness is 5nm; the electron transport layer BePP 2 , with a thickness of 40nm. Then deposit the electron injection layer LiF with a thickness of 1 nm and the metal cat...

Embodiment 3

[0041] Embodiment 3: Device [ITO / NPB / mCP / 4CzIPN:0.5%DCF 3 DB-QA / BCP / BePP 2 / LiF / Al]

[0042] The 15mm×15mm×1mm thick ITO conductive glass substrate was ultrasonically cleaned with ITO cleaning solution for 5 minutes, deionized water for 5 minutes, acetone for 20 minutes, and isopropanol for 20 minutes. After drying, plasma treatment for 5 minutes. In high vacuum 5 x 10 -5 The hole transport layer NPB was sequentially deposited under Pa with a thickness of 35nm; the first exciton blocking layer mCP was deposited with a thickness of 5nm; the light-emitting layer was deposited by double-source co-evaporation, in which the host material was 4CzIPN and the guest doping material was DCF 3 DB-QA, the doping concentration is 0.5% (weight percentage), the thickness is 30nm; the second exciton blocking layer BCP, the thickness is 5nm; the electron transport layer BePP 2 , with a thickness of 40nm. Then deposit the electron injection layer LiF with a thickness of 1 nm and the metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Band gap width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com