Steam water supply device for wine making boiler

A boiler and steam technology, applied in the field of brewing boiler steam water supply device, can solve the problems of heat dissipation loss, low thermal efficiency of small industrial boilers, etc., and achieve the effect of large jet flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in further detail below by means of specific embodiments:

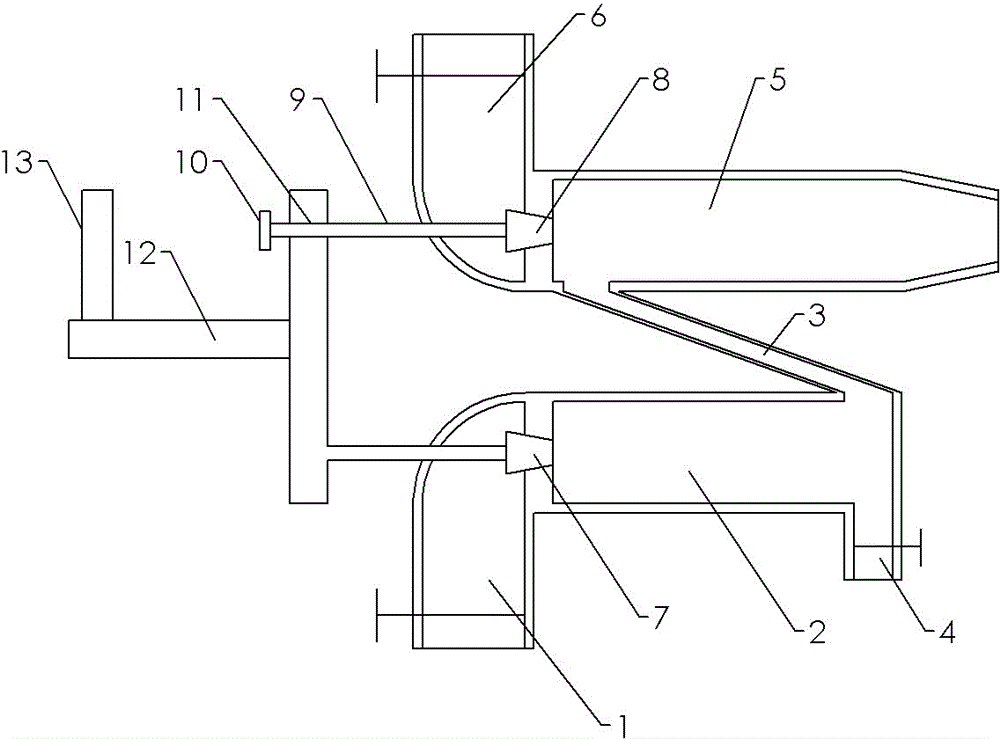

[0013] The reference signs in the drawings of the description include: water supply pipe 1, water inlet chamber 2, relay pipe 3, overflow port 4, jet chamber 5, steam pipe 6, valve core 7 in the water chamber, valve core in the jet chamber 8. Slide bar 9, bump 10, slide hole 11, drive rod 12, handle 13.

[0014] The embodiment is basically as attached figure 1 Shown: the upper part of the shell is the jet chamber, the lower part is the water inlet chamber, the outlet end on the right side of the water inlet chamber is connected to the inlet end of the jet chamber through a relay pipe, and the inlet end of the water inlet chamber is provided with a valve hole and connected to the water supply from below The pipeline and the water supply pipeline are used to supplement the water source. The jet cavity is connected to the steam pipeline through the valve hole at the inlet e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com