scroll compressor

A scroll compressor, compression chamber technology, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., can solve the problems of increase in the diameter of the check valve, productivity, difficulty in workability, etc., and achieve the injection flow rate. added effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Hereinafter, the present invention will be described with reference to illustrated embodiments.

[0023] In the following description, injection refers to recompressing the liquid refrigerant (on the high pressure side), or the two-phase refrigerant, or the gas refrigerant output from the condenser while returning to the compression chamber of the compressor. In addition, the (high-pressure side) liquid refrigerant, two-phase refrigerant, or gas refrigerant output from the condenser is referred to as an injection refrigerant. In addition, the term "after output from the condenser" is not limited to the refrigerant immediately after output from the condenser, and may be, for example, refrigerant after passing through a predetermined expansion valve, a predetermined heat exchanger, or the like. In addition, the condenser can also be interpreted as a radiator, a heat exchanger that applies heat to the load side, or a gas cooler.

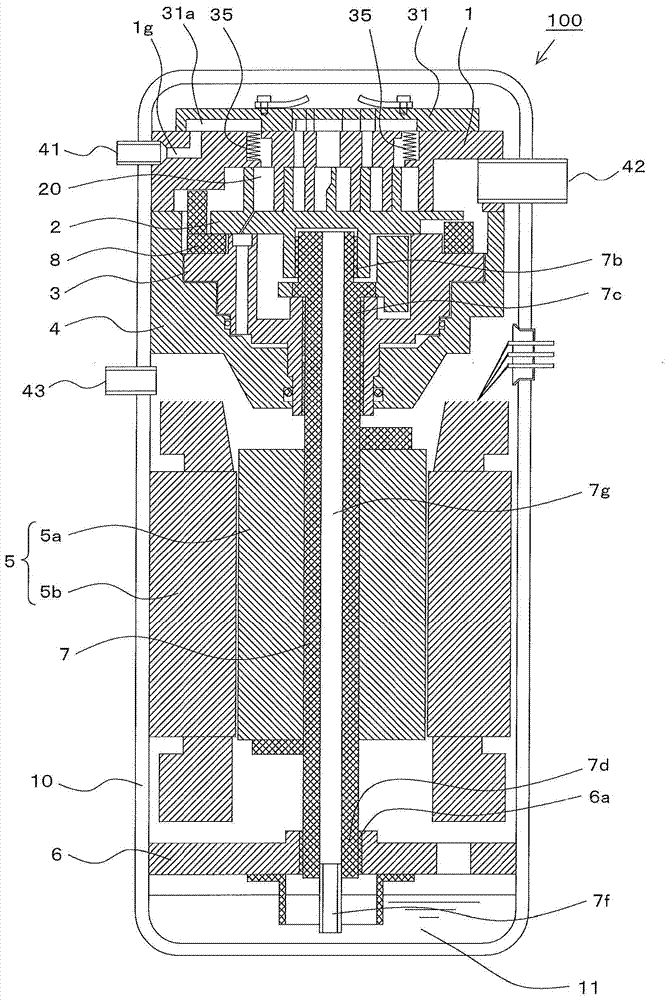

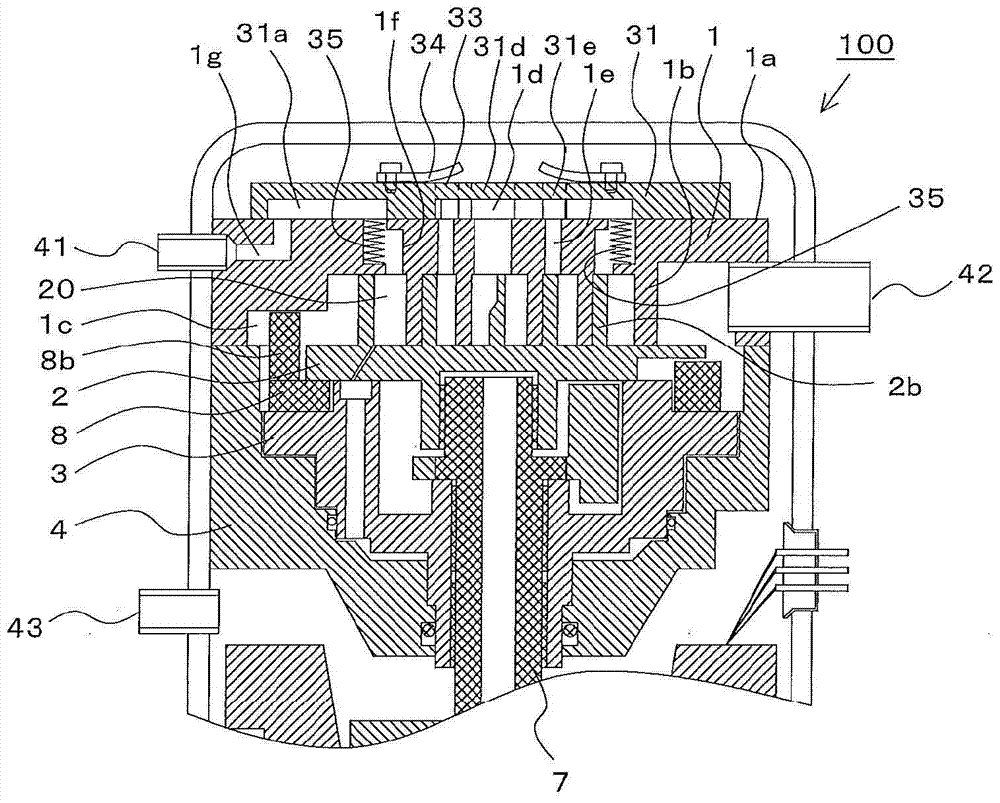

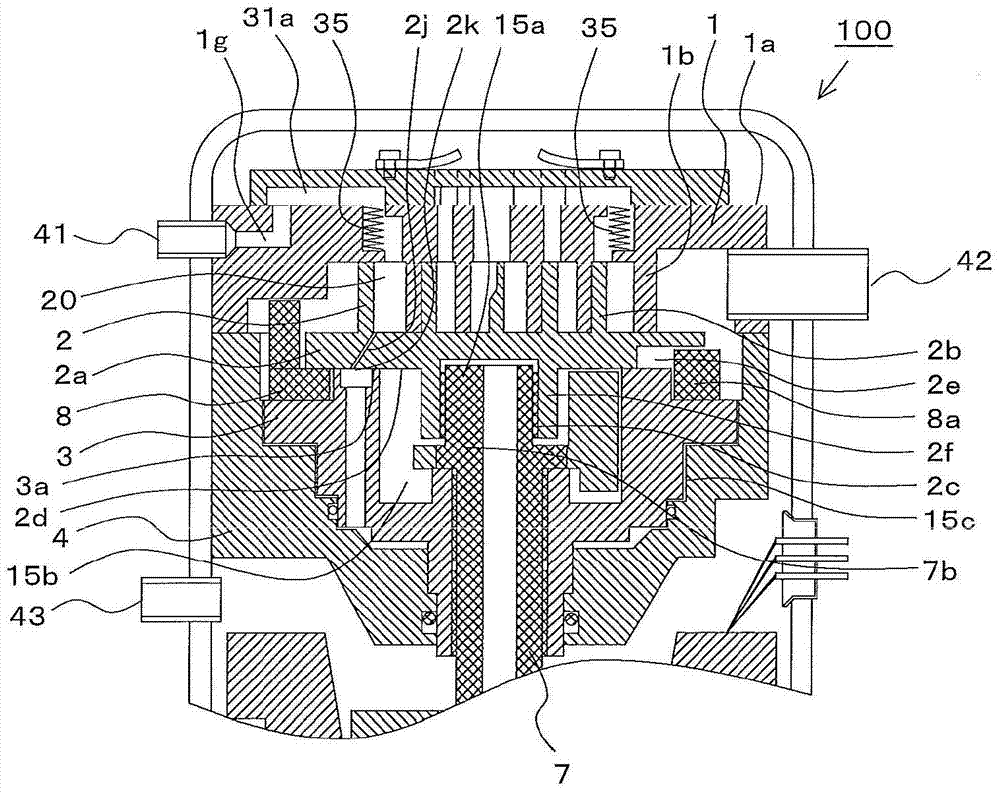

[0024] First, based on figure 1 The over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com