Extrusion production method of aluminum alloy seamless pipe with external variable diameter

A technology for seamless pipes and production methods, applied in the field of material processing engineering, can solve the problems of high processing cost, large processing volume, low material utilization rate, etc., to reduce processing costs, improve production efficiency and yield, and simple production methods Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

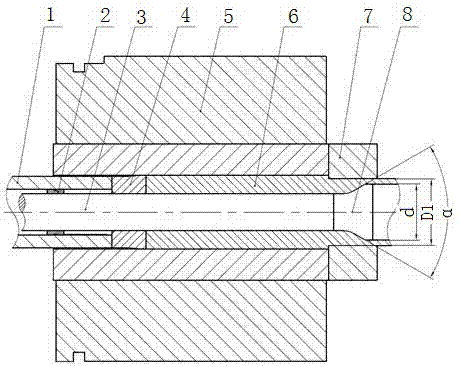

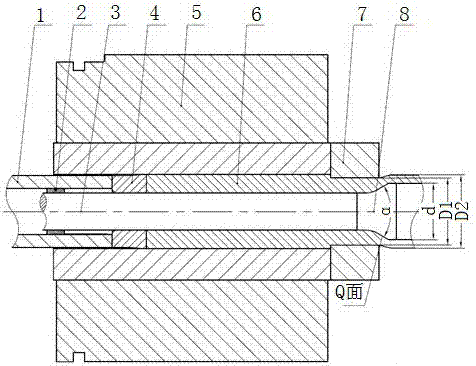

[0022] In order to overcome the problems of large machining volume, high processing cost and low material utilization rate in the traditional aluminum alloy seamless pipe processing method, the present embodiment provides an extrusion production method for an aluminum alloy seamless pipe with an outer variable diameter, which adopts The moving perforating needle 8 changes the gap between the perforating needle 3 and the extrusion die 7, thereby changing the outer diameter of the seamless pipe during the extrusion process, and the inner diameter of the seamless pipe is determined by the size of the head of the perforating needle 3, In this way, seamless pipes with constant inner diameter and increased outer diameter can be extruded.

[0023] Compared with the traditional processing method, the extrusion production method of the outer variable diameter aluminum alloy seamless pipe of the present invention not only greatly reduces the processing cost and processing technology of t...

Embodiment 2

[0025] On the basis of Embodiment 1, this embodiment provides an extrusion production method for an aluminum alloy seamless pipe with an outer variable diameter, and the method includes the following steps:

[0026] 1) During extrusion, the extrusion shaft (1) extrudes the billet (6) along the inside of the extrusion die (7) and the outside of the perforation needle (3) and the perforation needle (8) along the extrusion direction;

[0027] 2) When extruding with variable outer diameter, move the perforating needle (3) along the extrusion direction so that the big end of the perforating needle (8) is located outside the outlet of the extrusion die (7), and the bevel Q of the perforating needle (8) The surface is located at the exit of the extrusion die (7);

[0028] 3) The extrusion shaft (1) continues to extrude the billet (6) to flow along the extrusion direction, at this time, the inner diameter of the seamless pipe remains unchanged and the outer diameter becomes larger;

...

Embodiment 3

[0036] On the basis of Embodiment 2, this embodiment provides an extrusion production method of an aluminum alloy seamless pipe with an outer variable diameter, and the equipment used in the method is a double-action reverse extrusion equipment. The double-action reverse extrusion equipment is a double-action reverse aluminum and aluminum alloy extrusion device disclosed in Chinese Patent Application No. 200820228253.4, which does not belong to the protection scope of the present invention, and is not described in detail here.

[0037] Further, the perforating needle 8 is a bottle needle, and the length of the variable diameter section and the changed outer diameter of the outer variable diameter aluminum alloy seamless pipe are determined by the position of the perforating needle 3 and the angle α of the inclined plane Q of the perforating needle 8. ; This method realizes that the outer diameter of the outer diameter aluminum alloy seamless pipe becomes larger or smaller by co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com