Pressurizing changeable edge thread sleeve of parallel double-screw extruder

A technology of twin-screw extrusion and threaded sleeves, which is applied in the field of chemical machinery extruders, can solve the problems of small mixing and stirring, long twin-screws, and low occupancy rate of cone-twin extruders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

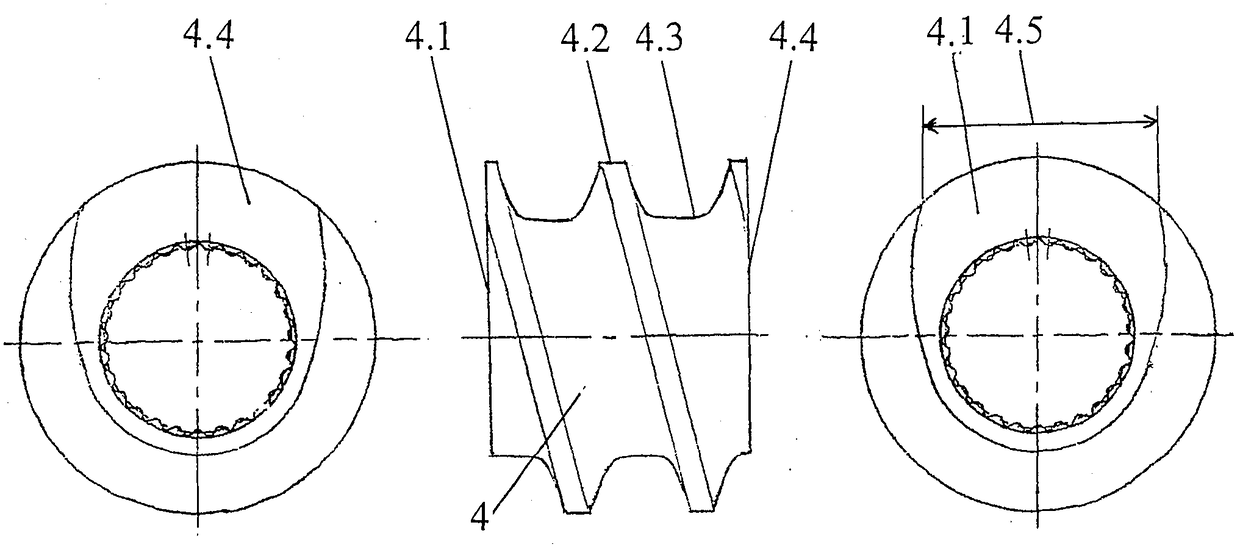

[0018] The specific implementation of this technology is that the last extrusion section of the parallel twin-screw extruder is a homogenization and extrusion section, all of which are 1-section cylinder, 2-section cylinder, 3-section cylinder or 4-section cylinder, This is to meet the homogenization and extrusion of different materials, some need to be short, and some need to be long, so the last row is usually between 6 to 26 threaded sleeves, while maintaining the outer diameter and inner diameter of the original conventional threaded sleeves and internal splines unchanged, starting from the output, figure 1 It is a general-purpose conventional double-ended threaded sleeve (1), the flight is a regular width screw flight (1.2), the screw groove is a regular width screw groove (1.3), the left side of the threaded sleeve (1.1) and the right side of the threaded sleeve ( 1.4) The shape and size are the same, and they are all regular width flight (1.5).

[0019] The first doubl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com