Control system and method for reducing oxynitride in coke oven waste gas

A control system and nitrogen oxide technology, which is applied in the heating of coke ovens, coke ovens, combustible gas heating coke ovens, etc., can solve the problems of large investment and high operating costs, achieve low investment costs, reduce emissions, and be easy to popularize and apply Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] specific implementation plan

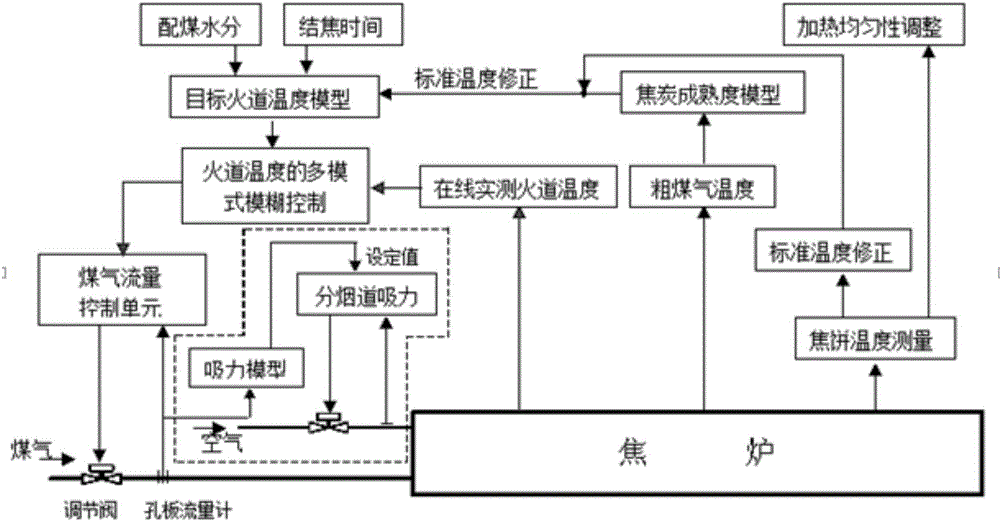

[0037] The most effective way to reduce nitrogen oxides in coke oven exhaust gas is to control NOx during combustion. In the coking production process, the nitrogen oxides generated when the gas is burned in the vertical flue of the coke oven are mainly nitrogen monoxide (NO), accounting for 95%, and nitrogen dioxide (NO2) is about 5%.

[0038] According to our research, most of the nitrogen oxides produced in the coking production process are caused by high temperature. There are two ways to control the flame temperature, the first is to dilute the concentration of combustible components in the fuel, and the second is to dilute the concentration of oxygen in the combustion-supporting gas (air), so that the fuel burns slowly in the fire channel, which can reduce the NOx Concentration can also improve the uniformity of heating in the high direction of the coke oven. The gas and air are mixed and burned in the combustion chamber, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com