Epoxy resin material for concrete joint repair and waterproofing and preparation method thereof

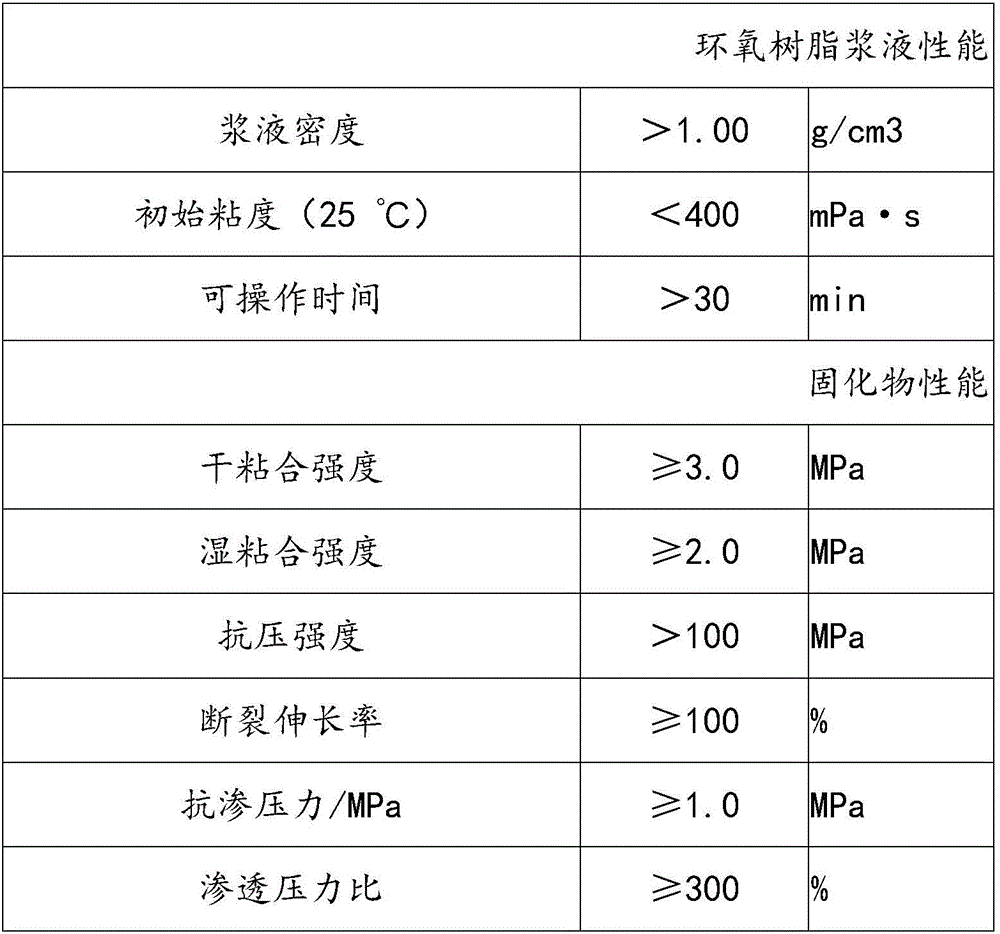

An epoxy resin and concrete technology, applied in building thermal insulation materials, building components, buildings, etc., can solve the problems that rigid materials cannot meet the needs of deformed joints, difficult to meet the needs of deformation joints, and can not meet the production leakage. Improved elongation at break and compression resistance, improved impermeability, and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The implementation and application of the original deformed joints of the concrete structure of the underground garage and the underground entrance and exit of the building when the rubber waterstop fails.

[0032] After the pre-grouting preparations are completed, the epoxy resin waterproof material is prepared. The specific ingredients and proportions are as follows:

[0033] Component A includes 70 parts of epoxy resin, 30 parts of heavy traffic asphalt, 30 parts of diluent, 18 parts of toughening agent, and 2 parts of coupling agent; put the epoxy resin of component A in a drying room at 60°C for 24 hours Standby, put the asphalt in component A in a heating container, heat up to 120°C and stir evenly for later use, prepare the heated epoxy resin and asphalt in component A according to the proportion, put them in the same container and mix and stir for 5- 10min, cool to 60°C, then configure the diluent, toughening agent, and coupling agent according to the proportion...

Embodiment 2

[0041] Subway shield tunnel segment geological subsidence, water seepage occurs in the ring joint of the segment, at this time, it is necessary to pour water-stop material into the ring joint of the segment.

[0042] First prepare the epoxy resin waterproof material, the specific composition and proportion are as follows:

[0043] Component A includes 60 parts of epoxy resin, 35 parts of heavy traffic asphalt, 33 parts of diluent, 20 parts of toughening agent, and 2 parts of coupling agent; put the epoxy resin of component A in a drying room at 60°C for 24 hours Standby, put the asphalt in component A in a heating container, heat up to 120°C and stir evenly for later use, prepare the heated epoxy resin and asphalt in component A according to the proportion, put them in the same container and mix and stir for 5- 10min, cool to 60°C, then configure the diluent, toughening agent, and coupling agent according to the proportion, place them in the same container and mix and stir for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com