Preparation method and application of functional material for adsorption of 10-hydroxy-2-decenoic acid

A technology of functional materials and royal acid, which is applied in material separation, analytical materials, chemical instruments and methods, etc., can solve the problems of uneven particle size, poor rigidity, low mass transfer speed, etc., and achieve uniform particle size, high selectivity and specificity. the effect of improving dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The invention discloses a method for preparing a functional material for adsorbing royal acid. A bulk polymerization method is used to prepare a molecularly imprinted polymer with royal acid as a template molecule. Dissolve 0.186g of royal acid in 10mL of methanol, and add 421μL of 4-vinylpyridine, 1514.7mg of N,N'-methylenebisacrylamide and 50mg of azobisisobutyronitrile in sequence. The reacted solution was purged with nitrogen gas for 10 minutes to remove oxygen, then placed in a water bath at 55° C., and thermally initiated polymerization for 24 hours. After the reaction, the mixed solution of methanol and glacial acetic acid with a volume ratio of 9:1 was Soxhlet-extracted for 24 hours, and methanol was used as solvent for 12 hours to wash off the residual glacial acetic acid, and vacuum-dried at 50°C to obtain the royal acid molecularly imprinted polymer .

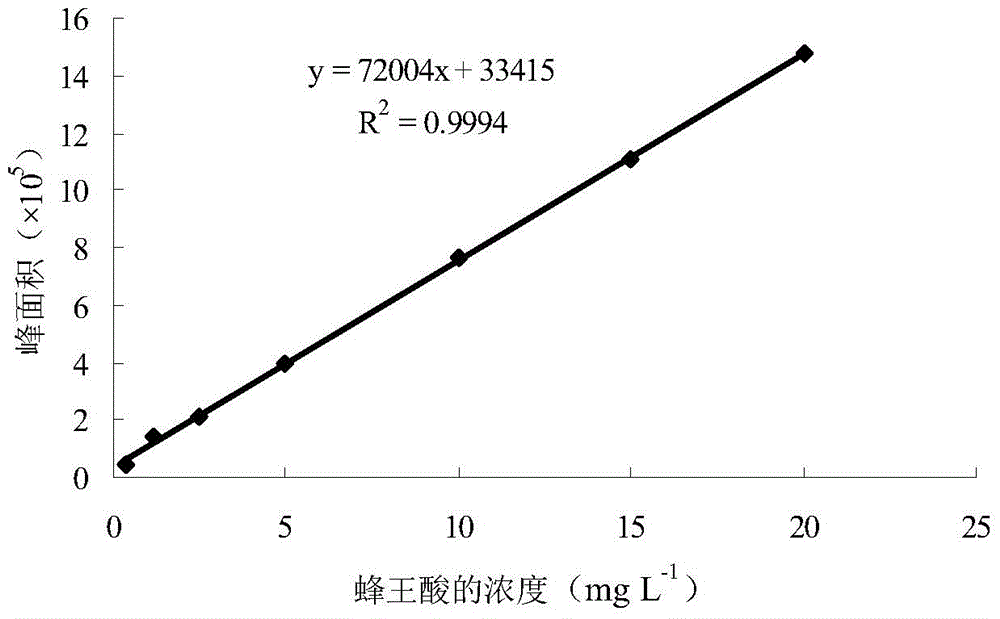

[0020] Accurately weigh 150 mg of the powdered royal acid adsorption material synthesized in Example 1, an...

Embodiment 2

[0022] The invention discloses a method for preparing a functional material for adsorbing royal acid. A bulk polymerization method is used to prepare a molecularly imprinted polymer with royal acid as a template molecule. Dissolve 0.3g of royal acid in 16mL of methanol, and add 674μL of 4-vinylpyridine, 2424mg of N,N'-methylenebisacrylamide and 80mg of azobisisobutyronitrile in sequence. The reacted solution was purged with nitrogen gas for 10 minutes to remove oxygen, then placed in a water bath at 55° C., and thermally initiated polymerization for 24 hours. After the reaction, the mixed solution of methanol and glacial acetic acid with a volume ratio of 9:1 was Soxhlet-extracted for 24 hours, and methanol was used as solvent for 12 hours to wash off the residual glacial acetic acid, and vacuum-dried at 50°C to obtain the royal acid molecularly imprinted polymer .

[0023] Accurately weigh 150 mg of the powdered royal acid adsorption material synthesized in Example 2, and pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com