High-sensitivity intelligent robot skin

An intelligent robot and sensitivity technology, which is applied in the field of intelligent sensing, can solve the problems of the tactile sensor being heavy, not high enough, and unable to have both the flexibility of human skin and the characteristics of multidimensional sensitivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The scheme of this application is further described in conjunction with the accompanying drawings as follows:

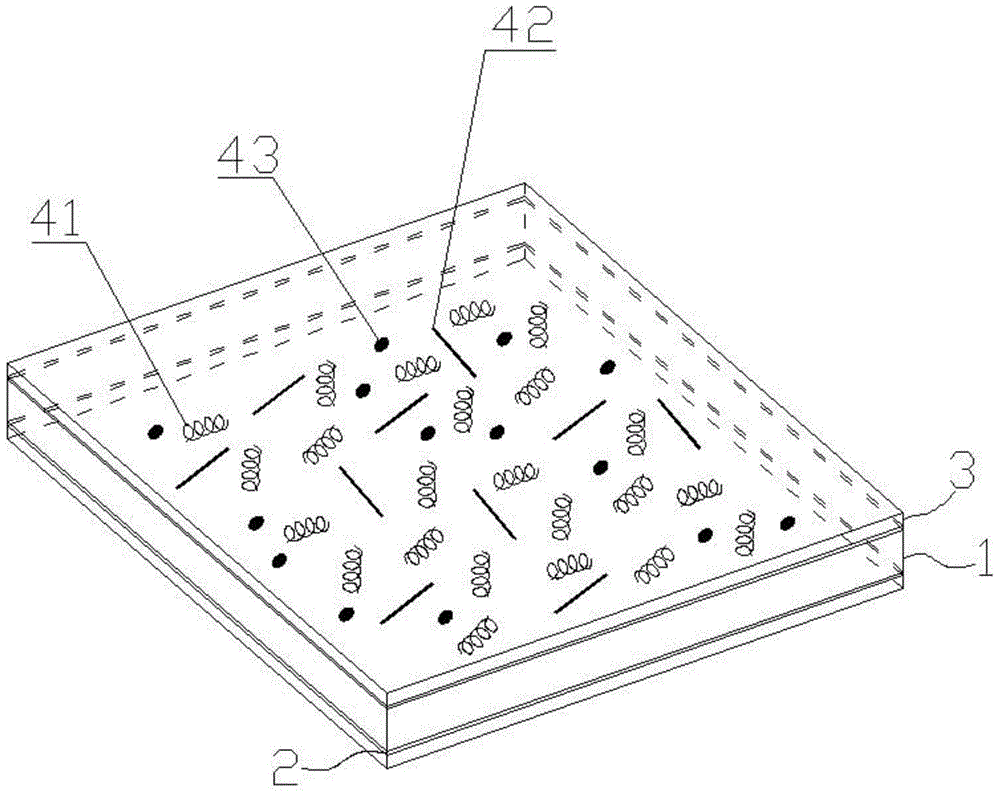

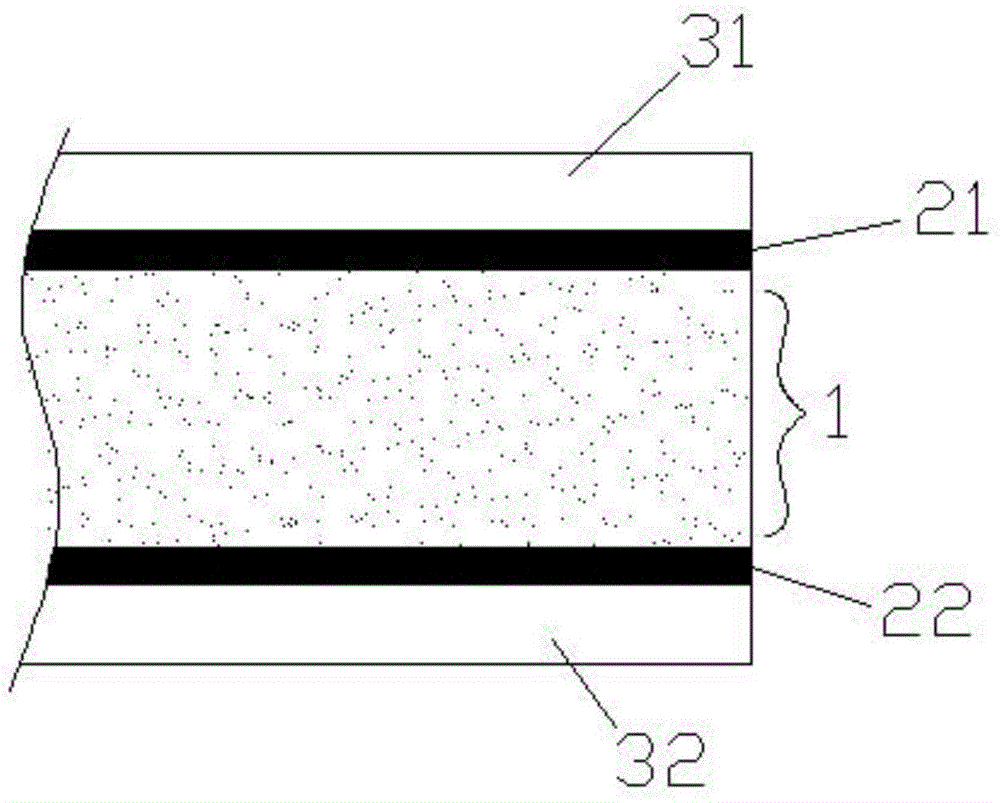

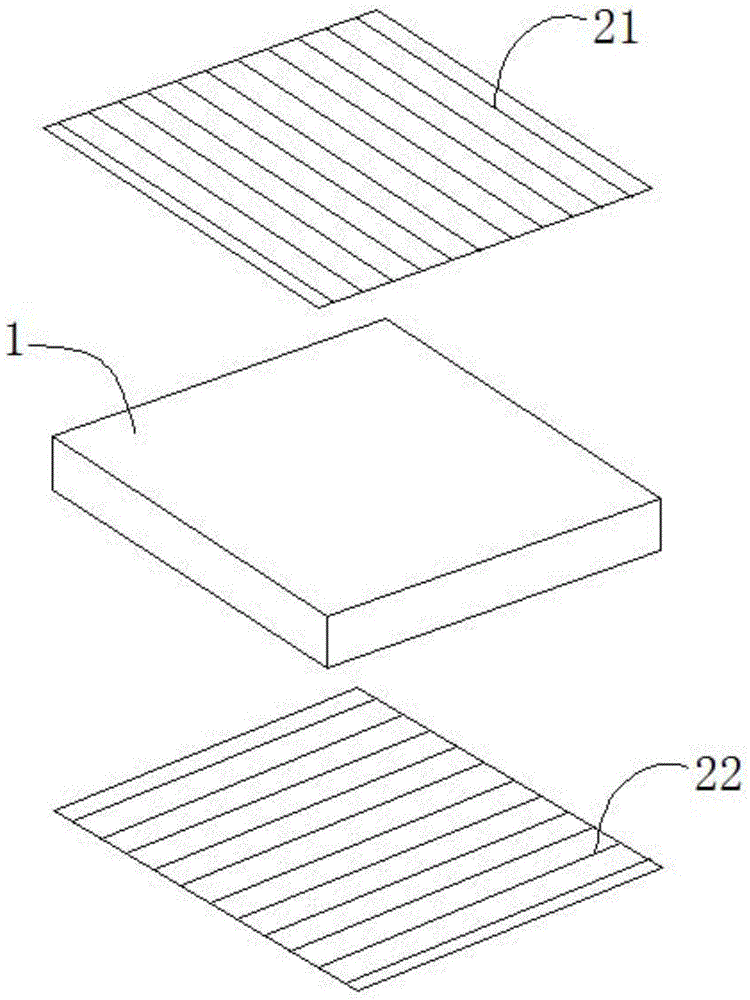

[0023] like figure 1 , 2 As shown in and 3, a high-sensitivity intelligent robot skin includes a composite layer 1 formed by doping a conductive monomer with a polymer in a certain proportion, plated on the electrode layer 2 on both sides of the composite layer 1, and wrapped in the electrode layer. The outer layer 3 on the outside of the layer 2, the conductive monomer includes conductive microsprings 41, conductive fibers 42 and conductive particles 43; among the present embodiment, the conductive fibers 42 are rod-shaped carbon fibers, and the conductive particles 43 are Carbon black and conductive monomers are randomly doped in the composite layer 1 , specifically, the conductive fibers 42 and conductive particles 43 are distributed in the gaps of the conductive microsprings 41 .

[0024] The composite layer 1, the electrode layer 2 and the outer layer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com