Method for extracting tobacco flavor from fireworks and applying it to snus

A technology for tobacco flavor and snus, which is applied in the field of snus, can solve problems such as solvent residue and insufficient safety, and achieve the effects of ensuring safety, avoiding waste of resources, and alleviating insufficient raw materials of tobacco leaves.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for extracting tobacco spices from fireworks and applying them to snus, comprising the following steps:

[0029] Step 1. Collect the fireworks in time after the tobacco is topped, and filter out the foreign matter;

[0030] Step 2. Pretreatment of different types of tobacco: the flue-cured tobacco fireworks are dried at a low temperature of 40-60°C, preferably 50°C, and the Burley tobacco fireworks and cigar smoke fireworks are dried in a ventilated room;

[0031] Step 3, sterilizing the pretreated dried fireworks with ultraviolet rays, preferably the radiation intensity of the ultraviolet sterilization is 20000-50000 μW / cm 2 , the time is 5-10s;

[0032] Step 4, crushing the sterilized fireworks to 10-80 mesh;

[0033] Step 5. Dissolve the pulverized sample in distilled water, the mass ratio of sample to distilled water is between 1:4 and 1:8, and stir and extract at 60-90°C for 0.5-1.5 hours. The experimental results show that: if the proportion of distill...

Embodiment 2

[0039] Collect the flue-cured tobacco and fireworks smeared by Daejeon, and sieve out the foreign matter. Bake at 50°C for 8h, at 30000μW / cm 2 Ultraviolet sterilization for 7s under irradiation intensity, pulverized and selected samples between 40-60 mesh sieves. The pulverized sample was dissolved in distilled water at a material-to-liquid ratio of 1:5, and stirred and extracted at 70°C for 1 hour. The extract was filtered and concentrated under reduced pressure at 60°C to twice the weight of the raw material. Add 5% raw material weight mixed enzyme (protease: pectinase: cellulase = 2:3:5) to the concentrated solution, and stir for 1.5 hours at a temperature of 50° C. and a pH value of 5.0 for enzymolysis. The obtained reaction solution was inactivated at 90°C, and freeze-dried at ultra-low temperature.

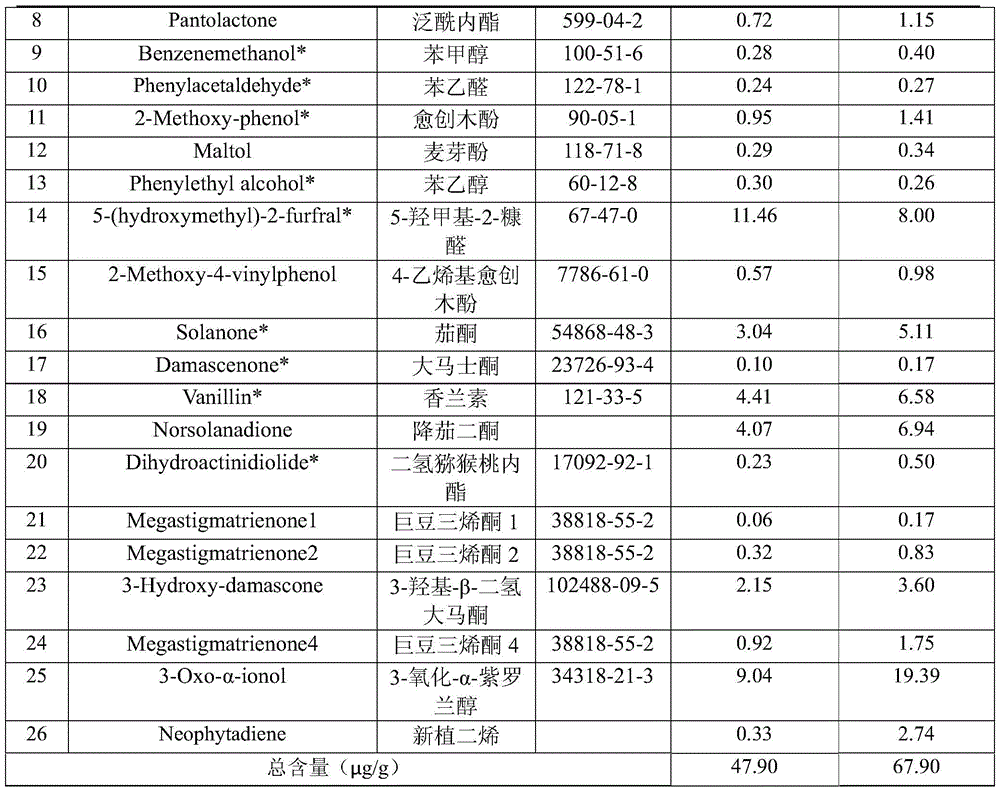

[0040] The content of aroma components in the concentrated solution before and after enzymolysis is shown in Table 1, and the change of nicotine content in the concentrat...

Embodiment 3

[0048] Collect the cigar fireworks wiped by Daejeon, and filter out the foreign matter. Dry overnight in a ventilated room at 50000μW / cm 2Under the irradiation intensity, ultraviolet sterilize for 5s, pulverize and select samples between 20 mesh and 40 mesh sieve. The pulverized sample was dissolved in distilled water at a material-to-liquid ratio of 1:8, and stirred and extracted at 80°C for 1 hour. The extract was filtered and concentrated under reduced pressure at 60°C to twice the weight of the raw material. Add 6% raw material weight mixed enzyme (protease: pectinase: cellulase = 3:2:3) to the concentrated solution, and stir for 1.5 hours at a temperature of 50°C and a pH value of 5.0 for enzymolysis. The obtained reaction solution was inactivated at 100°C, and freeze-dried at ultra-low temperature.

[0049] The content of aroma components in the concentrated solution before and after enzymolysis is shown in Table 3, and the change of nicotine content in the concentrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com