An ultrasonic positioning method for the core of a sic fiber reinforced ti-matrix composite ring

A composite material, fiber-reinforced technology, applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, can solve the problems of high cost, little meaning of control ring processing quality, insufficient image resolution, etc., and achieve the effect of saving manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

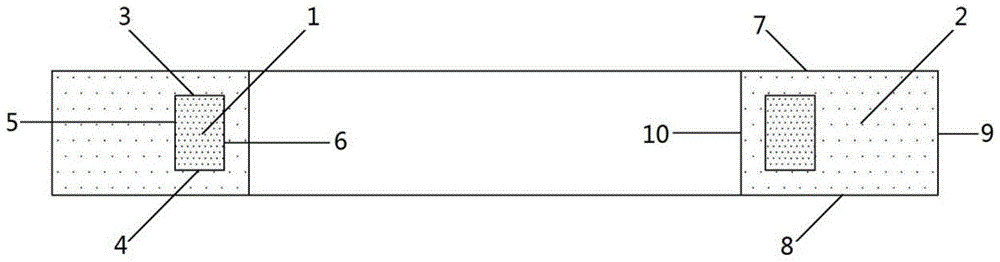

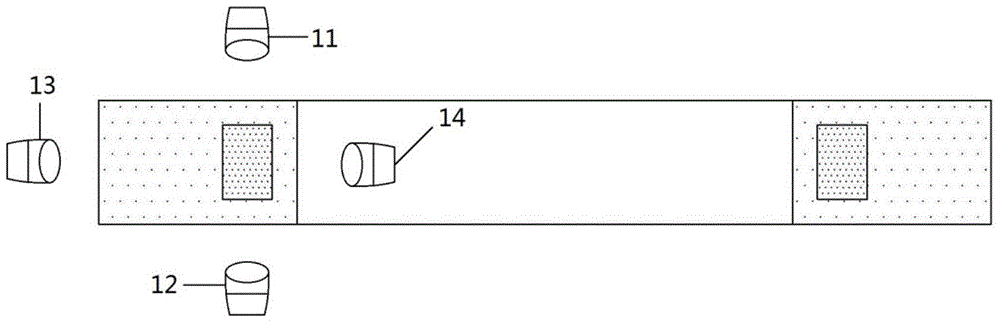

[0025] This embodiment uses SiC f / TC4 composite material ring is the test object. It is a sandwich structure composed of a composite material ring core and a surrounding Ti alloy outer sheath. The main dimensions of the internal structure are shown in Table 1. The interface between the ring core (core) and the Ti alloy outer sheath is diffusion welding. Connection, weld joint is good, no cracking. Such as figure 1 As shown, in the water immersion ultrasonic system, there are four interfaces of the ring from top to bottom (or from outside to inside), followed by the surface (the upper surface of the ring 7 or the outer surface of the ring 9), the ring core-outsourcing Sleeve interface (ring core upper surface 3 or ring core outer surface 5), ring core-outer sheath interface (ring core lower surface 4 or ring core inner surface 6), surface (ring lower surface 8 or ring inner surface 10) , so there are four strong echoes in the A-scan image of water immersion ultrasonic examin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com