An anti-sediment abrasion wear-resistant surfacing welding electrode

A technology for surfacing welding electrodes and sediments, applied in welding medium, welding equipment, welding equipment and other directions, can solve the problems of poor mechanical wear resistance and corrosion resistance comprehensive performance, achieve not easy to roll off and ensure anti-sand wear performance requirements, the effect of excellent stomatal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Weld core: diameter Ф3.2mm 1Cr13 stainless steel

[0024] Skin formula:

[0025] Marble 40%,

[0026] Fluorite 25%;

[0027] Rutile 9%;

[0028] Zircon 5%;

[0030] Ferrochromium nitride 4%;

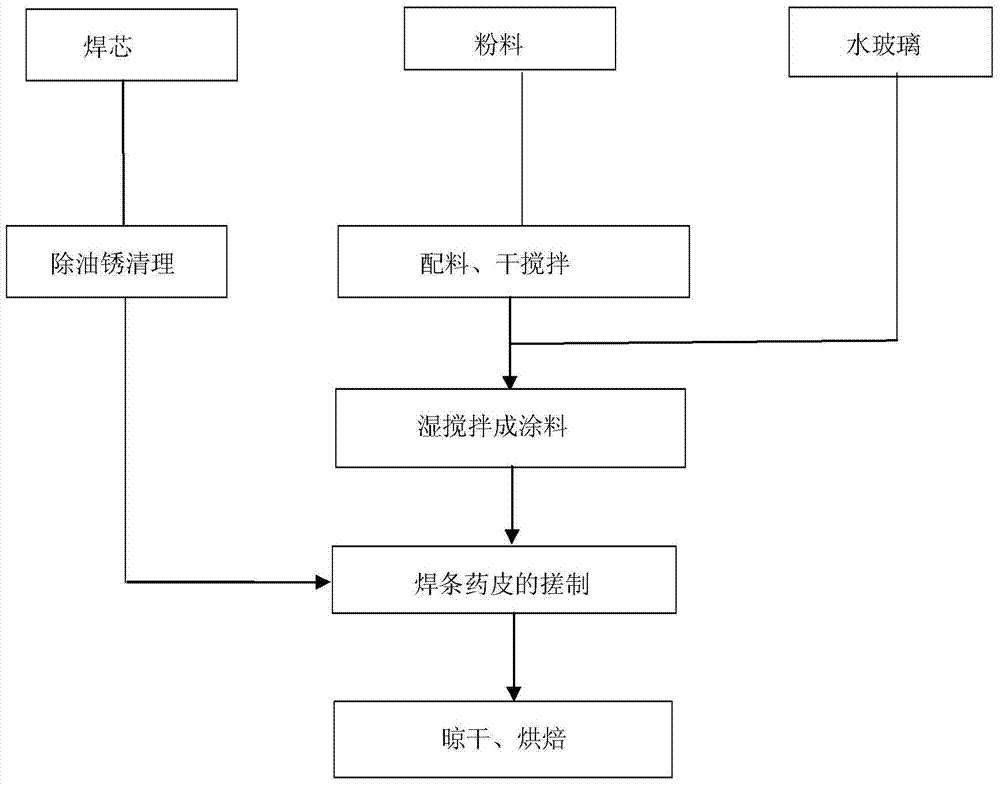

[0031] Titanium iron 12%. Preparation methods such as figure 1 As shown, the thickness of the coating is 1.5-2.0mm, and the average hardness of the electrode surfacing layer is HRC45.

Embodiment 2

[0033] Weld core: diameter Ф4.0mm 2Cr13 stainless steel

[0034] Skin formula:

[0035] Marble 45%,

[0036] Fluorite 20%;

[0037] Rutile 6%;

[0038] Zircon 4%;

[0040] Ferrochromium nitride 6%;

[0041] Titanium iron 15%. The preparation method is the same as in Example 1, the thickness of the coating is 1.7-2.2mm, and the average hardness of the electrode surfacing layer is HRC50.

Embodiment 3

[0043] Weld core: diameter Ф5.0mm 2Cr13 stainless steel

[0044] Skin formula:

[0045] Marble 30%,

[0046] Fluorite 30%;

[0047] Rutile 4%;

[0048] Zircon 3%;

[0049] Potassium feldspar 3%;

[0050] Ferrochromium nitride 10%;

[0051] Titanium iron 20%. The preparation method is the same as in Example 1, wherein the thickness of the coating is 2.0-2.5mm, and the average hardness of the electrode surfacing layer is HRC55.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com