A complete set of acid-free descaling equipment for steel strip surface and descaling method thereof

A technology of acid-free descaling and complete sets of equipment, which is applied in the field of hot-rolled steel processing, can solve the problems of acid mist, human hazards, heavy metal discharge, and large land occupation, so as to eradicate environmental pollution, save water resources, and occupy less land. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

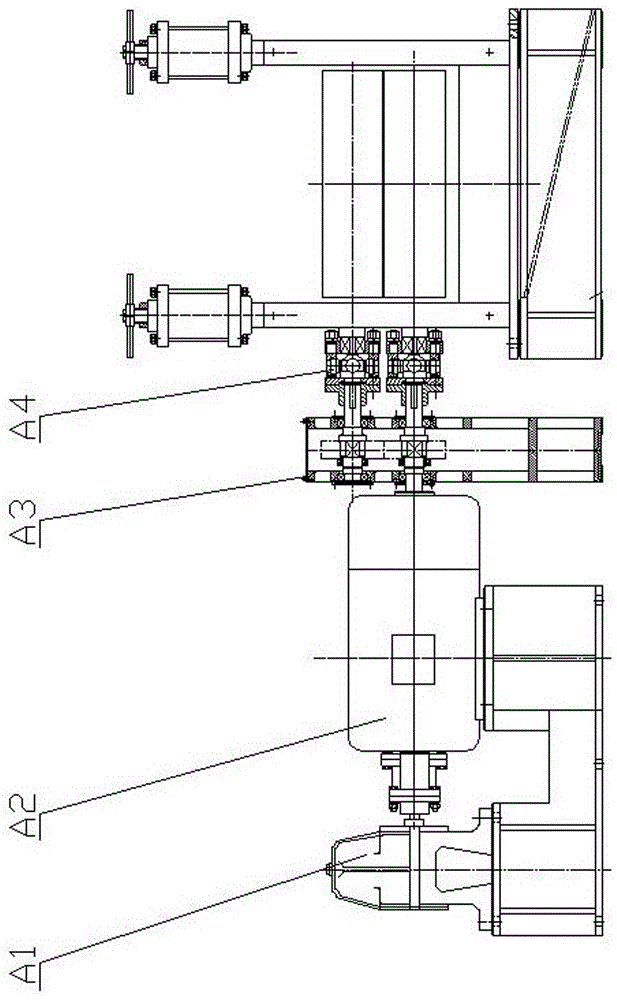

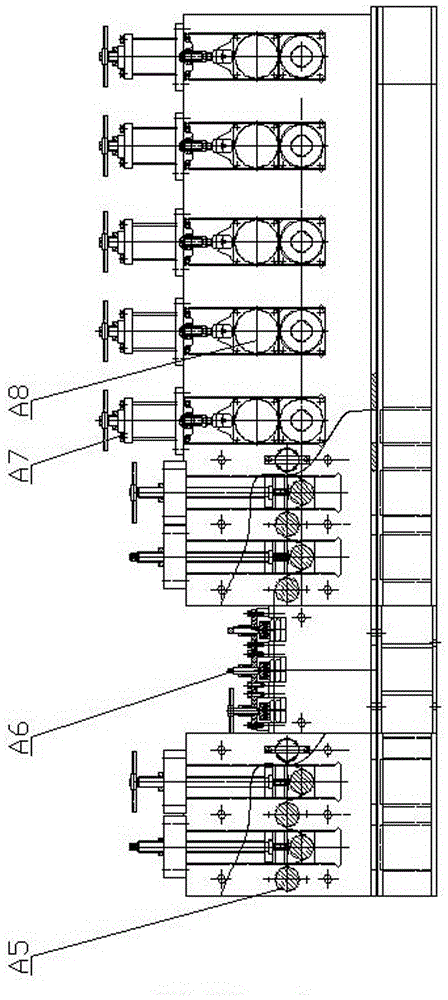

[0033] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 to attach Figure 8 , the strip steel surface acid-free descaling complete set of equipment of the present invention includes unwinding machine 1, feeding and pulling machine 2, hydraulic shear 3, welding machine 4, descaling polishing machine 5, green cloth dust-free Polishing machine 6, automatic balancing steel brush machine 7, six-roller synchronous pulling machine 8, passivation tank 9, winder 10; the descaling polishing machine 5 includes a reducer A1, a reduction motor A2, and ten-roller synchronous transmission Box A3, universal joint A4, multi-roller toothed descaling machine A5, 3M green cloth polishing machine A6, polishing machine adjustment device A7, pull belt friction roller A8; among them, the reducer A1 is installed at one end of the reducer frame to reduce the speed The input s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com