Axial-flow-type inverted inlet flow channel swirler

An inlet channel and axial flow technology, which is applied in the direction of swirling devices and devices whose axial direction can be reversed, can solve the problems of poor removal of fine oil droplets, high cost of membrane separation equipment, and removal of fine oil droplets. To solve problems such as limited capacity, achieve the effect of increasing the probability of collision coalescence and enhancing the effect of oil-water two-phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing:

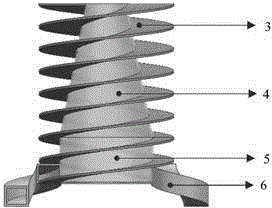

[0024] Such as Figure 1 to Figure 12 As shown, the technical solution involved in the present invention is funded by the National 863 Program Project (2012AA061303). This kind of axial flow reverse inlet channel cyclone is composed of overflow pipe 1, inlet pipe 2, spiral plate 3, hollow conical pipe 4, hollow cylindrical pipe 5, reverse spiral channel 6, enrichment pipe 7, cyclone The flow cavity 8, the cone section 9 and the bottom flow tube 10 are connected to form.

[0025] Among them, the swirl chamber 8 is a cylinder with a closed top, the top of the cone section 9 is sealed and connected to the bottom of the swirl chamber 8, and the bottom flow pipe 10 is fixedly connected to the bottom of the cone section 9; the inlet pipe 2 is a closed bottom The cylinder, the overflow pipe 1, the hollow conical pipe 4, the hollow cylindrical pipe 5 and the enrichment pipe 7 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com