Multiphase flow separation apparatus for semi-coke wastewater

A separation device, the technology of blue carbon wastewater, applied in water/sewage multi-stage treatment, centrifugal separation water/sewage treatment, grease/oily substance/float removal device, etc. The problems of unstable content and suspended solids content, and low efficiency of the method can achieve the effect of speeding up the separation of oil and water, facilitating maintenance and replacement, and improving efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be described in further detail below in conjunction with specific examples, but the embodiments of the present invention are not limited thereto.

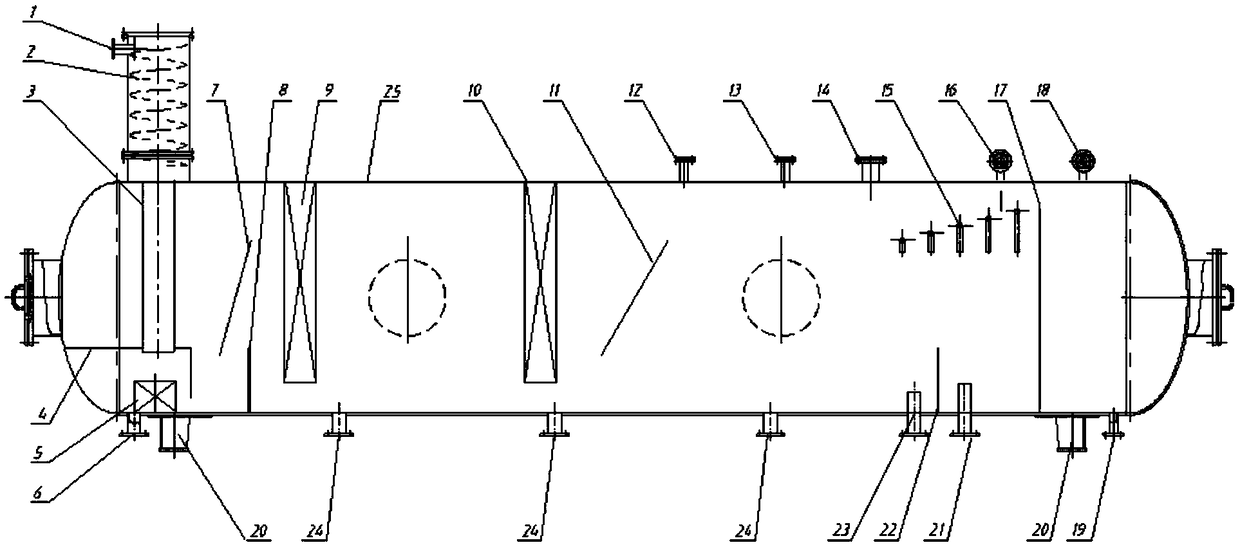

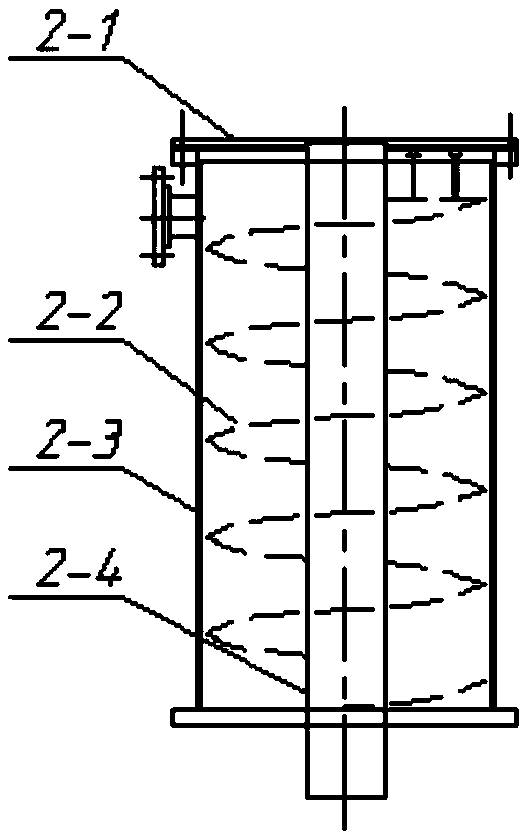

[0059] In order to solve the traditional semi-coke wastewater treatment process, after the semi-coke wastewater is directly settled in the sedimentation tank, the coal tar and solid suspended matter in the water are simply removed and directly used as quenching water, which affects the quality of the semi-coke; and the settlement of the sedimentation tank The treatment efficiency of the method is low, and the indicators of coal tar content and suspended solids content in the treated water are unstable. This embodiment provides a semi-coke wastewater multiphase flow separation device, which can effectively separate the light Oil, heavy oil, and sludge are separated, and the wastewater after the semi-coke wastewater multiphase flow separation device can ensure the oil content index requirements in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| oil removal rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com