Reverse osmosis membrane with polyvinylamine grafted on surface, and preparation method thereof

A polyvinylamine, reverse osmosis membrane technology, applied in reverse osmosis, semi-permeable membrane separation, chemical instruments and methods, etc. The effect of pollution performance, wide source of raw materials and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

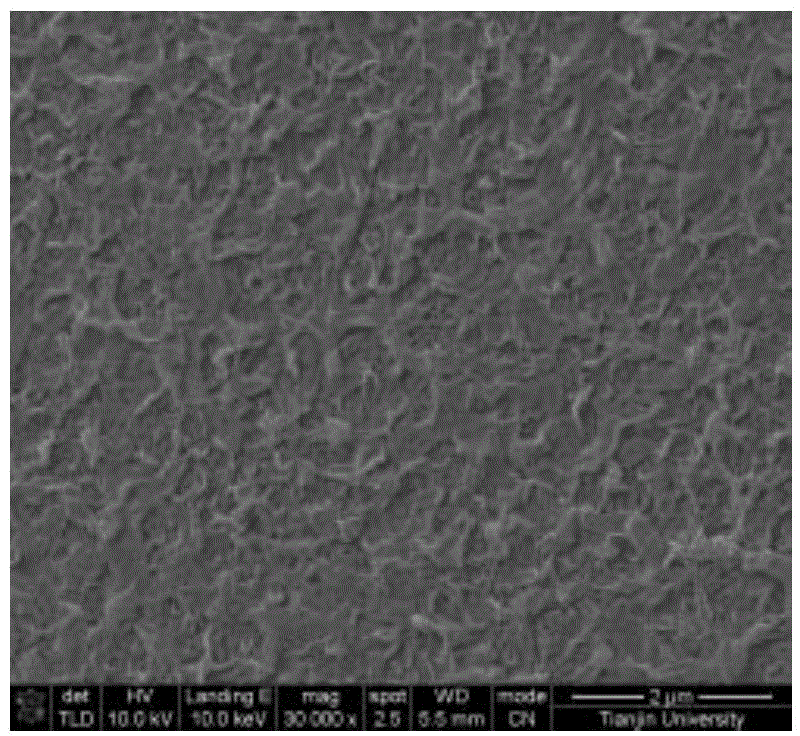

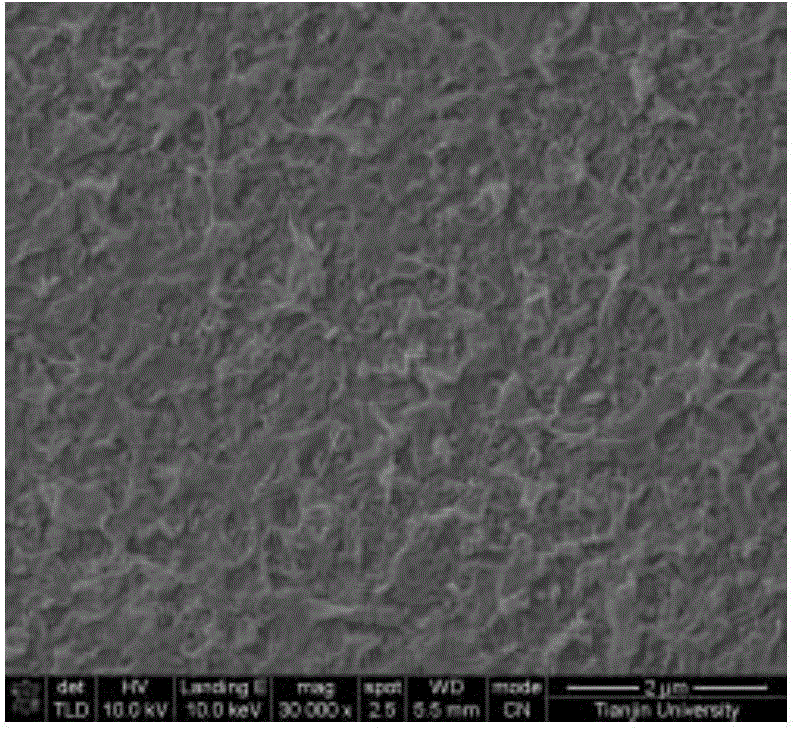

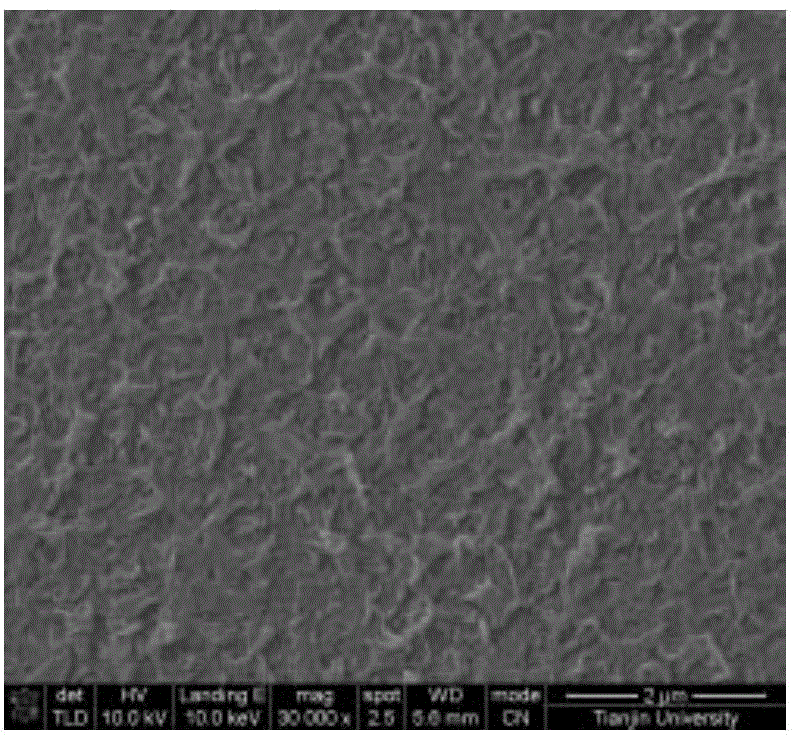

Image

Examples

Embodiment 1

[0023] (1) Fix an aromatic polyamide composite reverse osmosis membrane with a size of 13 × 11 cm between two plexiglass frames and a rectangular hollow silica gel pad. The rectangular hollow silica gel pad has the same size as the plexiglass frame, and fully rinse with deionized water. reverse osmosis membrane surface;

[0024] (2) Prepare 25 mL of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution with a mass fraction of 1%, and quickly pour the aqueous solution on the membrane surface to completely wet the aqueous solution film surface;

[0025] (3) preparation 25ml mass fraction is the N-hydroxyl succinimide aqueous solution of 8%, pours on the reverse osmosis membrane containing 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution On the surface, shake slowly to mix completely;

[0026] (4) Prepare 25ml of an aqueous solution of polyvinylamine with a mass fraction of 0.05%, then pour the solution on the surface of the me...

Embodiment 2

[0034] (1) Fix an aromatic polyamide composite reverse osmosis membrane with a size of 25 × 20 cm between two plexiglass frames and a rectangular hollow silica gel pad. The rectangular hollow silica gel pad has the same size as the plexiglass frame, and rinse thoroughly with deionized water reverse osmosis membrane surface;

[0035] (2) Prepare 50 mL of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution with a mass fraction of 6%, and quickly pour the aqueous solution on the membrane surface to completely wet the aqueous solution film surface;

[0036] (3) preparation 50ml mass fraction is the N-hydroxysuccinimide aqueous solution of 5%, pours on the reverse osmosis membrane containing 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution On the surface, shake slowly to mix completely;

[0037] (4) Prepare 50 ml of an aqueous solution of polyvinylamine with a mass fraction of 0.50%, then pour the solution on the surface of the...

Embodiment 3

[0042] (1) Fix an aromatic polyamide composite reverse osmosis membrane with a size of 50 × 40 cm between two plexiglass frames and a rectangular hollow silica gel pad. The rectangular hollow silica gel pad has the same size as the plexiglass frame, and fully rinse with deionized water. reverse osmosis membrane surface;

[0043] (2) Prepare 150 mL of 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution with a mass fraction of 4%, and quickly pour the aqueous solution on the membrane surface to completely wet the aqueous solution film surface;

[0044] (3) preparation of 150mL mass fraction is 10% N-hydroxysuccinimide aqueous solution, poured on the reverse osmosis membrane containing 1-(3-dimethylaminopropyl)-3-ethylcarbodiimide hydrochloride aqueous solution On the surface, shake slowly to mix completely;

[0045] (4) Prepare 150ml of an aqueous solution of polyvinylamine with a mass fraction of 0.25%, then pour the solution on the surface of the mem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

| Salt rejection | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com