A kind of preparation method for the cellulose composite membrane that is used for adsorbing heavy metal ions

A technology for adsorbing heavy metals and bacterial cellulose membranes, applied in alkali metal compounds, chemical instruments and methods, adsorption water/sewage treatment, etc., can solve problems such as high operating costs, incomplete treatment, secondary pollution, etc., and achieve environmental protection , Saving polymer solution and saving cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

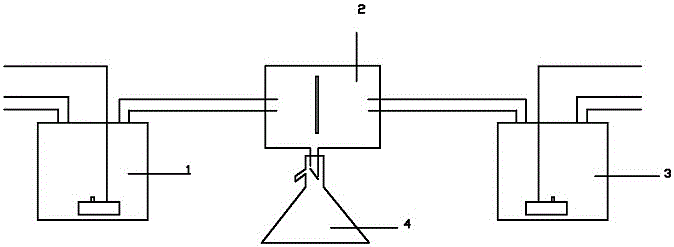

[0032] Wash the bacterial cellulose membrane repeatedly with deionized water according to the above method, put the cleaned bacterial cellulose membrane in 300ml distilled water with 6g sodium hydroxide, 6g azodicarbonamide, 0.6g Span-80, and then in 60 ℃ for 1 h, and then washed with deionized water. Configure 0.5mol / L pyrrole solution and 0.25mol / L FeCl 3 solution. The pyrrole solution with a concentration of 0.5 was charged into the first nebulizer reactor (1), and the first reactor (1) was placed in a cooling water bath, and the FeCl solution with a concentration of 0.25 3 The solution is loaded into the third atomization reactor (3), and the third reactor (3) is placed in a cold water bath, and the treated bacterial cellulose membrane is placed in the middle of the second reactor (2), and the bacterial cellulose The membrane plane is perpendicular to the center line of the atomization pipeline, and the atomizers and gas flow bottles in the first atomization reactor (1) ...

Embodiment 2

[0034] Wash the bacterial cellulose membrane repeatedly with deionized water according to the above method, put the cleaned bacterial cellulose membrane in 400ml distilled water with 8g sodium hydroxide, 8g azodicarbonamide, 0.8g Span-80, and then in 60 ℃ for 1 h, and then washed with deionized water. Configure 1mol / L pyrrole solution and 0.5mol / LFeCl 3 solution. The pyrrole solution is loaded into the first atomizer reactor (1), and the first reactor (1) is placed in a cooling water bath, and the FeCl 3 The solution is loaded into the third atomization reactor (3), and the third reactor (3) is placed in a cold water bath, and the treated bacterial cellulose membrane is placed in the middle of the second reactor (2), and the bacterial cellulose The membrane plane is perpendicular to the center line of the atomization pipeline, and the atomizers and gas flow bottles in the first atomization reactor (1) and the third atomization reactor (3) are opened at the same time, so that...

Embodiment 3

[0036] Wash the bacterial cellulose membrane repeatedly with deionized water according to the above method, put the cleaned bacterial cellulose membrane in 500ml distilled water with 10g sodium hydroxide, 10g azodicarbonamide, and 1g Span-80, and then heat it at 60°C It was treated at constant temperature for 1 h, and then washed with deionized water. Configure 1.5mol / L pyrrole solution and 0.75mol / LFeCl 3 solution. The pyrrole solution is loaded into the first atomizer reactor (1), and the first reactor (1) is placed in a cooling water bath, and the FeCl 3The solution is loaded into the third atomization reactor (3), and the third reactor (3) is placed in a cold water bath, and the treated bacterial cellulose membrane is placed in the middle of the second reactor (2), and the bacterial cellulose The membrane plane is perpendicular to the center line of the atomization pipeline, and the atomizers and gas flow bottles in the first atomization reactor (1) and the third atomiza...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com