Plate heat exchanger having sealed construction

A technology of plate heat exchanger and heat exchange plate, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., and can solve problems such as heat exchanger leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

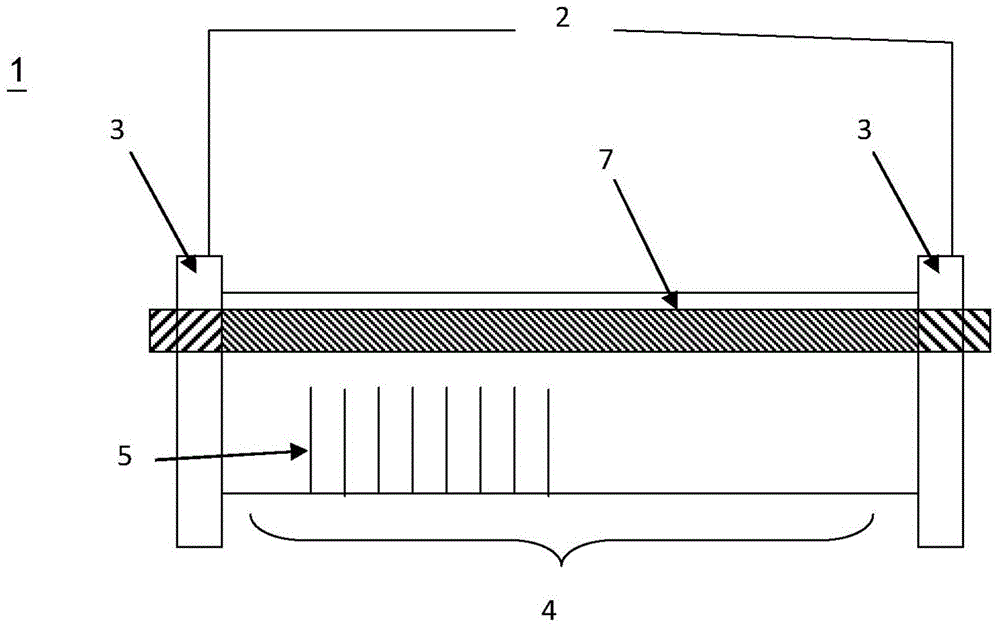

[0051] figure 1 A plate heat exchanger ( 1 ) according to the invention comprising a frame body consisting of two frame plates ( 3 ) is shown. A plate stack (4) of heat exchange plates is arranged between the frame plates (3). Also shown is the force applying means (7).

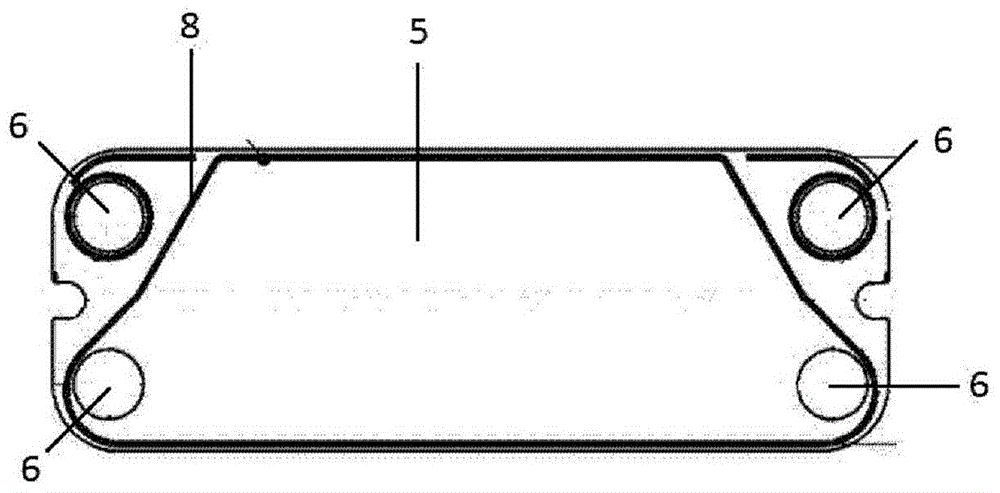

[0052] figure 2 The profile of the heat exchange plates ( 5 ) of the plate stack ( 4 ) (not shown) is shown, including means 6 for feeding and discharging fluid medium and sealing means 8 . It can be seen that the sealing means (8) separate the feed means and the discharge means (6) from each other in a sealed manner.

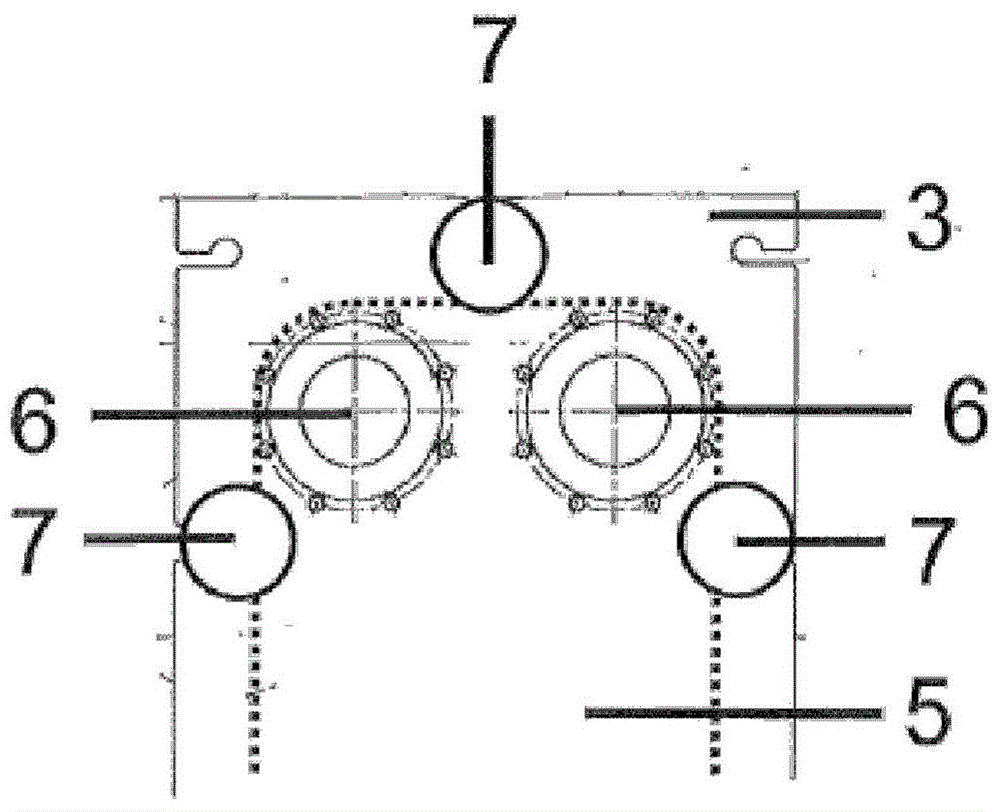

[0053] image 3 The outlines of the frame plate (3) and the heat exchange plate (5) are shown as well as the two devices (6) for feeding and discharging the fluid medium and the three force applying devices (7) indicated by black circles. It can be seen how the center of gravity of the force application surface in all force application devices is outside the area created by the linear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com