A production method of moisture-absorbing and breathable antibacterial ultra-high molecular weight polyethylene blended core-spun yarn

An ultra-high molecular weight, moisture-absorbing and breathable technology, which is applied in the production field of moisture-absorbing, breathable, antibacterial, and ultra-high molecular weight polyethylene blended core-spun yarns, and can solve the problems of high modulus of ultra-high molecular weight polyethylene fibers, no wearability, and natural fiber comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

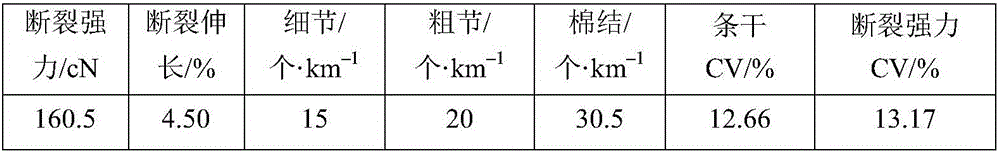

[0042] Taking the production of 18.5tex moisture-absorbing and breathable antibacterial ultra-high molecular weight polyethylene blended core-spun yarn on the QFA1528 compact spinning frame as an example, the specific production plan is as follows: mix bamboo fiber and polyester fiber and make the first cotton lap; The lint cotton is made into the second lap; the first lap is made into raw sliver; the second lap is made into combed sliver; the first raw sliver and combed The roving process is made into roving; the ultra-high molecular weight polyethylene filament is double-twisted to obtain the ultra-high molecular weight polyethylene filament double-twisted yarn; the core-spun yarn production method is adopted in the spinning process, in which the roving is fed by the rear roller through the bell mouth, The ultra-high molecular weight polyethylene filament two-for-one twisted yarn is fed by the front roller through the wire guide device, and the hygroscopic and breathable anti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com